- Product Details

- {{item.text}}

Quick Details

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Chemxin

-

Model Number:

-

CMS-220

-

Diameter:

-

1.1-1.3MM

-

Adsorbent pressure:

-

0.75-0.8 Mpa

-

Dust level:

-

≤100 PPM

-

Bulk Density:

-

630-680 KG/M3

-

Crushing strength:

-

≥100 N/P

-

Nitrogen purity:

-

99.999 N2%

-

Certification:

-

BV

-

Quality Management:

-

ISO9001, ISO14001, OHSAS18001

-

Keywords:

-

CMS 220 carbon molecular sieve

-

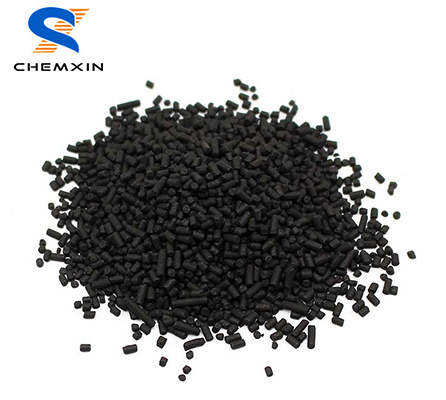

Appearance:

-

Black, Extruded (Pellet)

Quick Details

-

CAS No.:

-

1318-02-1

-

Purity:

-

100%

-

Other Names:

-

CMS

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Chemxin

-

Model Number:

-

CMS-220

-

Diameter:

-

1.1-1.3MM

-

Adsorbent pressure:

-

0.75-0.8 Mpa

-

Dust level:

-

≤100 PPM

-

Bulk Density:

-

630-680 KG/M3

-

Crushing strength:

-

≥100 N/P

-

Nitrogen purity:

-

99.999 N2%

-

Certification:

-

BV

-

Quality Management:

-

ISO9001, ISO14001, OHSAS18001

-

Keywords:

-

CMS 220 carbon molecular sieve

-

Appearance:

-

Black, Extruded (Pellet)

Product Description

Carbon Molecular Sieve

Customer Case

On-site guidance for carbon molecular sieves replacement

Chemxin 3 technicians went to ZhuHai electronics factory to guide replacement of carbon molecular sieve according to the customers' requirements. The nitrogen production of the generator is 100 m3 / h, and the nitrogen purity is required to be more than 99.9%.

Specification

|

Model

|

|

|

Carbon Molecular Sieve

|

|

|||

|

Appearance

|

|

|

Black, extruded(pellet)

|

|

|||

|

Nominal pore diameter

|

|

|

4 angstroms

|

|

|||

|

Diameter (mm)

|

|

|

0.95mm, 1.1-1.3mm, 1.3-1.5mm, 1.5-1.8mm

|

|

|||

|

Crushing strength (The test temperature≤20℃)

|

|

|

>50 N/PC

|

|

|||

|

Bulk Density

|

|

|

630-680 KG/M3

|

|

|||

|

Dust level

|

|

|

100PPM Max

|

|

|||

|

Adsorbent time (S) (The test temperature≤20℃)

|

|

|

2*50(can be adjusted)

|

|

|||

|

Type

|

Adsorption Pressure (MPa)

|

N2 Purity(%)

|

N2 quantity (M3/T.MT)

|

Air/N2 (%)

|

|||

|

CMS-220

|

0.75-0.8

|

99.999

|

55

|

6.8

|

|||

|

|

|

99.99

|

100

|

4.8

|

|||

|

|

|

99.9

|

145

|

3.7

|

|||

|

|

|

99.5

|

220

|

2.6

|

|||

|

|

|

99

|

260

|

2.4

|

|||

|

|

|

98

|

300

|

2.3

|

|||

|

|

|

97

|

340

|

2.2

|

|||

|

|

|

96

|

380

|

2.1

|

|||

|

|

|

95

|

420

|

2.0

|

|||

Typical Application

a) Be used to separate air into N2 and O2.

b) Be applied in petroleum chemical, heat treatment, electronic and food preservation industries.

How a PSA Nitrogen Generator System Works:

Recommend Products

Hot Searches