- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Online Support

-

Steel strip material:

-

SS

-

Application:

-

Cold rolling

-

Motor power:

-

26.5KW

-

Roller working speed:

-

6 turns/min

-

Steel strip thickness:

-

2 mm -6mm

-

Steel strip width:

-

30 mm-120mm

-

Spiral blade inner diameter:

-

25-110 mm

-

Weight:

-

2500kg

-

Product name:

-

Continuous Helical Flight Spring Blade Forming Machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

bobo

-

Weight (KG):

-

9000

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Online Support

-

Steel strip material:

-

SS

-

Application:

-

Cold rolling

-

Motor power:

-

26.5KW

-

Roller working speed:

-

6 turns/min

-

Steel strip thickness:

-

2 mm -6mm

-

Steel strip width:

-

30 mm-120mm

-

Spiral blade inner diameter:

-

25-110 mm

-

Weight:

-

2500kg

-

Product name:

-

Continuous Helical Flight Spring Blade Forming Machine

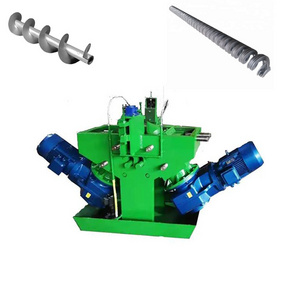

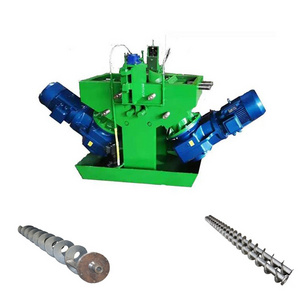

High Quality Wear Resistant Continuous Helical Screw Spiral Auger Feeder

Flight Spring Blade Forming Machine For Poultry Farm

Description

The spiral blade cold rolling mill is a special

cold rolling machine for continuous rolling of spiral blades from coiled strip steel. It can roll the required blades of various specifications by adjusting the adjustment parts (roll offset, feeding height, rolling pressure, guide wheel, etc.). The continuous forming spiral blade cold rolling machine is designed with conical rolls, the strip steel can be cold rolled through the rolls to produce continuous spiral blades, replacing the traditional cold drawing forming process.

Application

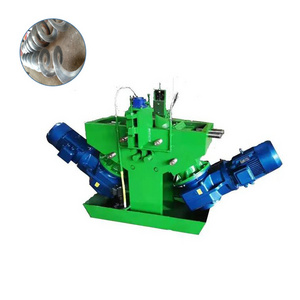

1. Spiral blade cold rollers are suitable for agricultural machinery parts, harvesting machines, bagging machines.

2. Spiral blade cold rollers are applied to spiral flights of concrete mixing machinery.

3. Spiral vane cold rollers are used in spiral flights for food processing machinery.

4. Spiral vane cold rollers are applied to blowers and lifts.

5. Spiral vane cold rollers are applied to shaftless screw conveyors, etc.

Details

Processing Effect Display

Parameter Main Data

|

NO.

|

Item

|

Parameter

|

|

|

||

|

1

|

Model

|

BB-270

|

BB-350

|

BB-400

|

||

|

2

|

Working mode

|

Mechanical

|

Mechanical

|

Hydraulic

|

||

|

3

|

The thickness of rolled strip

|

2-5mm

|

2-6mm

|

2-8mm

|

||

|

4

|

The width of the strip rolling

|

≤90mm

|

≤130mm

|

≤150mm

|

||

|

5

|

ID

|

25-90mm

|

25-110mm

|

30-110mm

|

||

|

6

|

OD

|

90-270mm

|

90-350mm

|

90-400mm

|

||

|

7

|

Pitch of screw thread

|

80-230mm

|

80-300mm

|

80-350mm

|

||

|

8

|

Rolled speed

|

1-6r/min

|

1-6r/min

|

1-6r/min

|

||

|

9

|

Main motor working speed

|

1440r/min

|

1440r/min

|

980r/min

|

||

|

10

|

Main power

|

26.5kw

|

26.5kw

|

34kw

|

||

|

11

|

Gross weight

|

6t

|

6.7t

|

9t

|

||

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Hot Searches