- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

Customized

-

CrO Content (%):

-

Customized

-

SiC Content (%):

-

Customized

-

Place of Origin:

-

Henan, China

-

Model Number:

-

SK30/32/34/35/36/37/38/40

-

Brand Name:

-

XinJia

-

Product name:

-

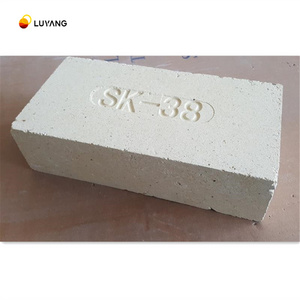

High Alumina Brick

-

Application:

-

Industrial Furnaces

-

Color:

-

Light Yellow

-

Certificate:

-

CE ISO

-

Feature:

-

High Temperature Resistant

-

Sample:

-

Avaliable

-

Package:

-

Wooden Pallet

-

Delivery time:

-

7-15 DAYS

-

Advantage:

-

High Thermal Stability

-

Keyword:

-

High Aluminium Brick

Quick Details

-

SiO2 Content (%):

-

Customized

-

Al2O3 Content (%):

-

48%-85%

-

MgO Content (%):

-

Customized

-

CaO Content (%):

-

Customized

-

CrO Content (%):

-

Customized

-

SiC Content (%):

-

Customized

-

Place of Origin:

-

Henan, China

-

Model Number:

-

SK30/32/34/35/36/37/38/40

-

Brand Name:

-

XinJia

-

Product name:

-

High Alumina Brick

-

Application:

-

Industrial Furnaces

-

Color:

-

Light Yellow

-

Certificate:

-

CE ISO

-

Feature:

-

High Temperature Resistant

-

Sample:

-

Avaliable

-

Package:

-

Wooden Pallet

-

Delivery time:

-

7-15 DAYS

-

Advantage:

-

High Thermal Stability

-

Keyword:

-

High Aluminium Brick

Products Description

High alumina brick

High alumina bricks have an alumina content greater than 46% and are made from high purity bauxite and clay raw materials. High alumina bricks have excellent mechanical strength, good resistance to thermal spalling, and good resistance to chemical attack by volatile alkanes and certain slags, making them suitable for harsh conditions of use. Through quality control, Xinjia Refractories produces and designs high alumina bricks to meet the requirements of various service conditions.

Indicators of high alumina bricks

|

Item/Grade

|

Fire Clay Brick

|

|

|

|

High Alumina Brick

|

|

|

|

|||||||

|

|

SK-30

|

SK-32

|

SK-34

|

SK-35

|

SK-36

|

SK-37

|

SK-38

|

SK-40

|

|||||||

|

AL2O3% (≥)

|

30

|

35

|

38

|

45

|

55

|

65

|

70

|

82

|

|||||||

|

Fe2O3% (≤)

|

2.5

|

2.5

|

2

|

2

|

2

|

2

|

2

|

2

|

|||||||

|

Refractoriness(SK)

|

30

|

32

|

34

|

35

|

36

|

37

|

38

|

40

|

|||||||

|

Refractoriness Under Load, 0.2MPa, °C (≥)

|

1250

|

1300

|

1360

|

1420

|

1450

|

1480

|

1530

|

1600

|

|||||||

|

Apparent Porosity (%)

|

22-26

|

20-24

|

20-22

|

18-20

|

20-23

|

20-23

|

20-22

|

18-20

|

|||||||

|

Bulk Density (g/cm³)

|

1.9-2.0

|

1.95-2.1

|

2.1-2.2

|

2.15-2.22

|

2.25-2.4

|

2.3-2.5

|

2.4-2.6

|

2.5-2.7

|

|||||||

|

Cold Crushing Strength ,MPa (≥)

|

20

|

25

|

30

|

40

|

45

|

50

|

60

|

70

|

|||||||

|

Size

|

Standard: 230*114*65 mm, or Customization accepted

|

|

|

|

|

|

|

|

|||||||

Advantages of high alumina brick

1.High Refractoriness

2.High Temperature Strength

3.High Thermal Stability

4High Compressive Strength

5.Neutral Refractory

6.High Refractoriness Under Load

7.High Temperature Creep Resistance

8.Low Apparent Porosity

9.Long Service Life, Easy Operation

Applications of High Alumina Brick

High Alumina Bricks Application

1.Used for masonry lining of steel making furnaces,glass furnaces ,cement rotary furnaces.

2. Used for blast stoves , electric furnace tops , for hot blast stoves , electric furnace tops ,blast furnaces , reverberatory furnaces ,rotary kiln linings.

3. Alumina Fire Bricks are also widely used as open-air regenerative lattice bricks ,plugs for gating systems , and nozzle bricks.

Production Process of High alumina brick

Hot Searches