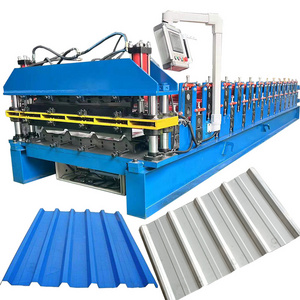

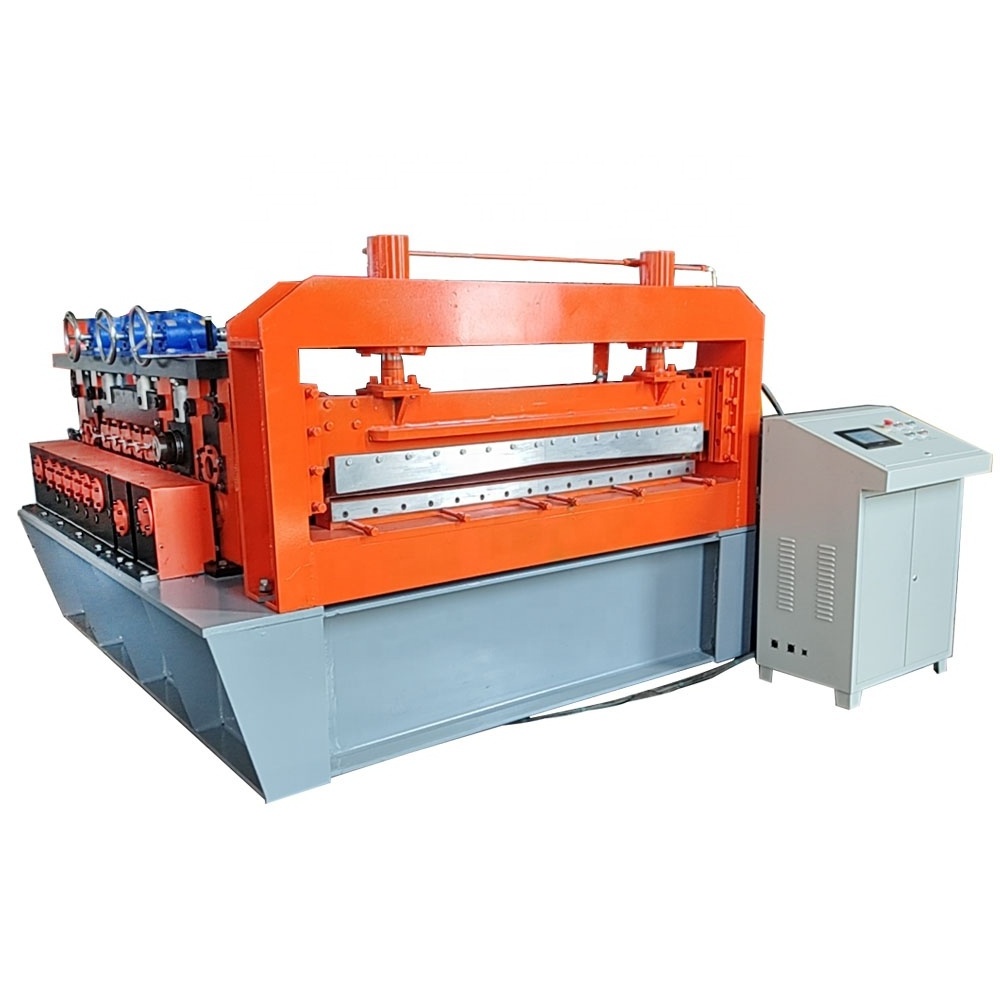

Hydraulic Ibr Trapezoid Roofing Sheet Tile Making Machinery Roll Forming Machine

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Wow

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

860*150*160cm

-

Weight:

-

5 kg

-

Marketing Type:

-

New Product 2021

-

type:

-

1050mm

-

raw material:

-

1250mm

-

main power:

-

4kw

-

control system:

-

PLC(imported Brand)

-

Roller Diameter:

-

85mm

-

Power Supply:

-

as your need

-

thickness:

-

0.3-0.8mm

-

After Warranty Service:

-

Video technical support

-

LocalService Location:

-

None

-

Aftersales Service Provided:

-

Free spare parts

Quick Details

-

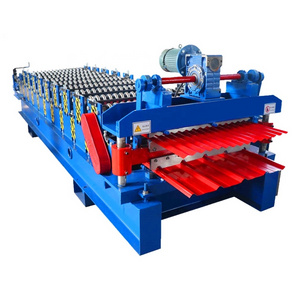

Type:

-

Tile Forming Machine

-

Tile Type:

-

colored

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Wow

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

860*150*160cm

-

Weight:

-

5 kg

-

Marketing Type:

-

New Product 2021

-

type:

-

1050mm

-

raw material:

-

1250mm

-

main power:

-

4kw

-

control system:

-

PLC(imported Brand)

-

Roller Diameter:

-

85mm

-

Power Supply:

-

as your need

-

thickness:

-

0.3-0.8mm

-

After Warranty Service:

-

Video technical support

-

LocalService Location:

-

None

-

Aftersales Service Provided:

-

Free spare parts

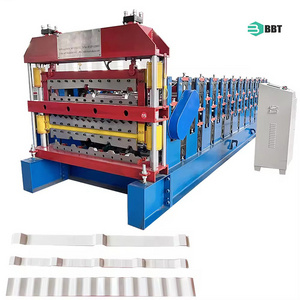

Recommend Products

cnc tile cutting leveling machine

The function of this machine is to cut the plate to the length of the plate you need. It can be used together. Manual operation is required.

Product Paramenters

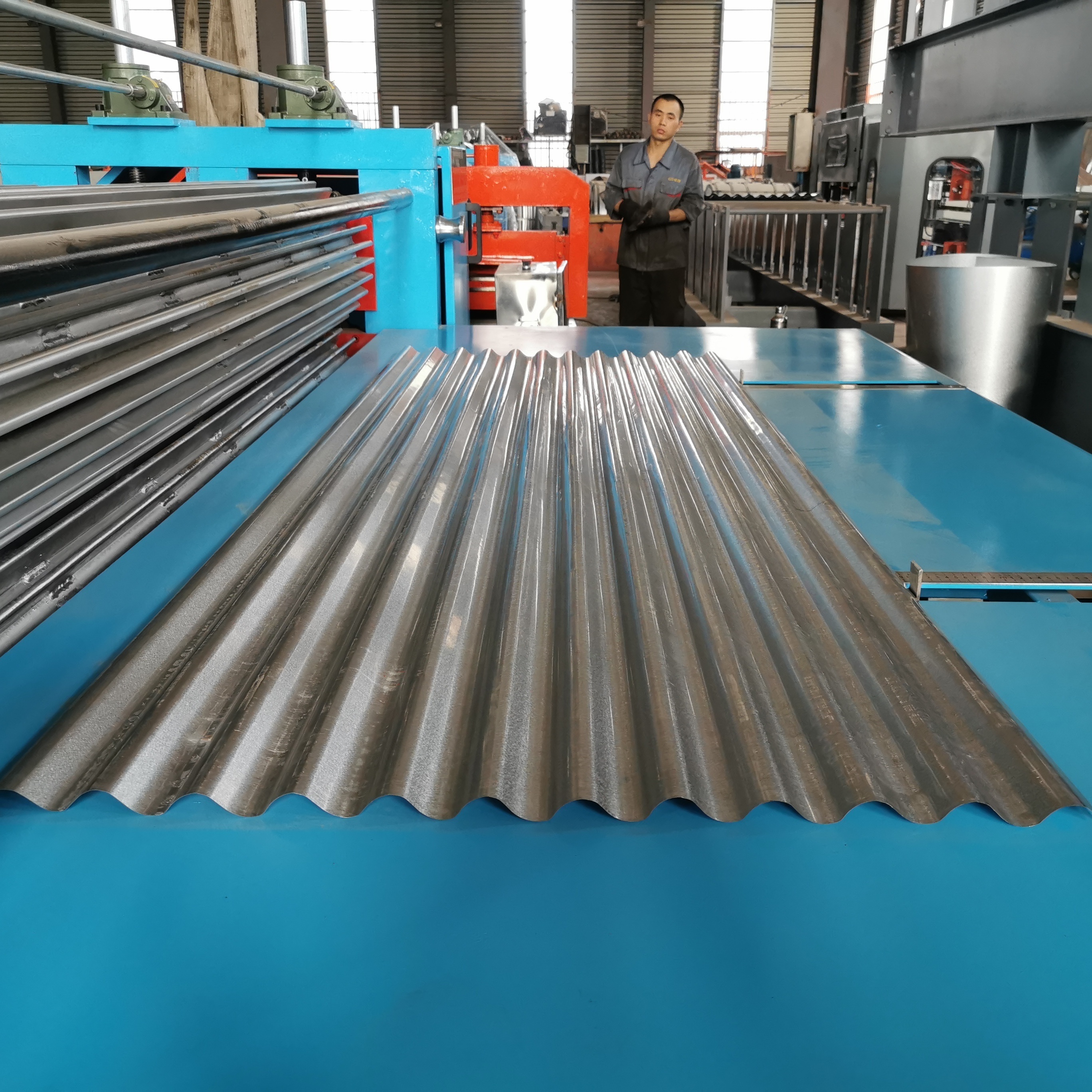

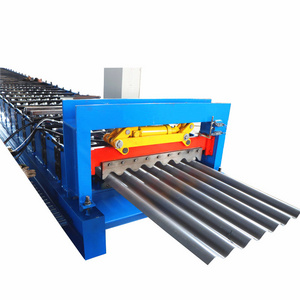

corrugated iron roofing zinc sheet roll forming machine

|

1

|

Suitable to process

|

Color steel plate

|

|

2

|

Width of the plate

|

914mm/1000mm/1200mm/1220mm/1250mm

|

|

3

|

Thickness of the plate

|

0.3-0.8mm

|

|

4

|

De-coiler

|

Manual one, can load 5 tons raw material

|

|

5

|

Rollers for forming

|

16 rows

|

|

6

|

Diameter of the roller

|

80mm

|

|

7

|

Rolling material

|

Carbon Steel 45#

|

|

8

|

Main motor power

|

5.5kw

|

|

9

|

Material of the cutting blade

|

Cr12 mov

|

|

10

|

Hydraulic cutting power

|

4kw

|

|

11

|

Processing precision

|

Within 1.00mm

|

|

12

|

Control system

|

Delta PLC control

|

|

13

|

Side panel of machine

|

16mm

|

|

14

|

Main structure of the machine

|

350 H steel

|

|

15

|

Weight

|

About 5T

|

|

16

|

Dimensions

|

8.5*1.6*1.6m

|

|

17

|

Voltage

|

380V 50Hz 3phases(changeable as needs)

|

|

18

|

Certificate

|

CE/ISO

|

|

19

|

Custom

|

According to customer's requirements

|

The production process

Raw material → machining → base plate production→shot blasting → painting → assemby →debugging → packed product → shipments.

Picture Details

product application

Machine product application

1.

A minimum workshop area of 100 square meters is recommended for the purchase of the machine.

2.

The production speed is 500-720 meters per hour, and 1-2 workers are required to support the work of the machine.

Our Advantages

NEW CNC MILLING

It make the backboard of purlin machine, also make the holes on backboard. This milling machine can milling the backboard more level, hole place is more precious. This can make the roller more level after installing,and then the purlin will be more straight.

ELECTRICAL CONTROL

All the control system of our machines we make by ourselves. we have a professional engineer to design and make the control system. This can make sure the after-sale service, when customer have problem with control, we can solve it timely.

LARGE CNC MILLING MACHINE

it is a unique plant in Hebei Province.It directly mills the entire frame. The milling machine can make the ‘machine's large surface smoother and the machine is more perfect.

MACHINING

This line, have high precious CNC grinders and milling machines, to make the rollers and shafts of the machine.After produce, have professional engineer to check if these are qualified.

From one roller to one machine, we do every step carefully to make sure the quality.

ENVIRONMENT-FRIENDLY SPRAYING EQUIPMENT

The electrostatic spraying equipment meets the environmental protection regulations of the Chinese government and guarantees the delivery time of the machine.

Hot Searches