- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SONGSHUN

-

Product name:

-

1.2379/ D2/ SKD10 hot Mould Steel

-

Surface:

-

Bright / black

-

Steel making processes:

-

EAF+LF+VD

-

Formed technique:

-

Hot rolled or hot forged

-

Delivery condition:

-

Pre-harden (<=235HBW )

-

MOQ:

-

1TON

-

Heat Treatment:

-

Annealed:760-790℃

-

Main Application:

-

For pre-hardend pouring medium and large plastic mold

Quick Details

-

Steel Grade:

-

Alloy steel

-

Tolerance:

-

±1%

-

Grade:

-

Alloy steel

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SONGSHUN

-

Product name:

-

1.2379/ D2/ SKD10 hot Mould Steel

-

Surface:

-

Bright / black

-

Steel making processes:

-

EAF+LF+VD

-

Formed technique:

-

Hot rolled or hot forged

-

Delivery condition:

-

Pre-harden (<=235HBW )

-

MOQ:

-

1TON

-

Heat Treatment:

-

Annealed:760-790℃

-

Main Application:

-

For pre-hardend pouring medium and large plastic mold

Product name: D2/ 1.2379 Hot tool mold Steel

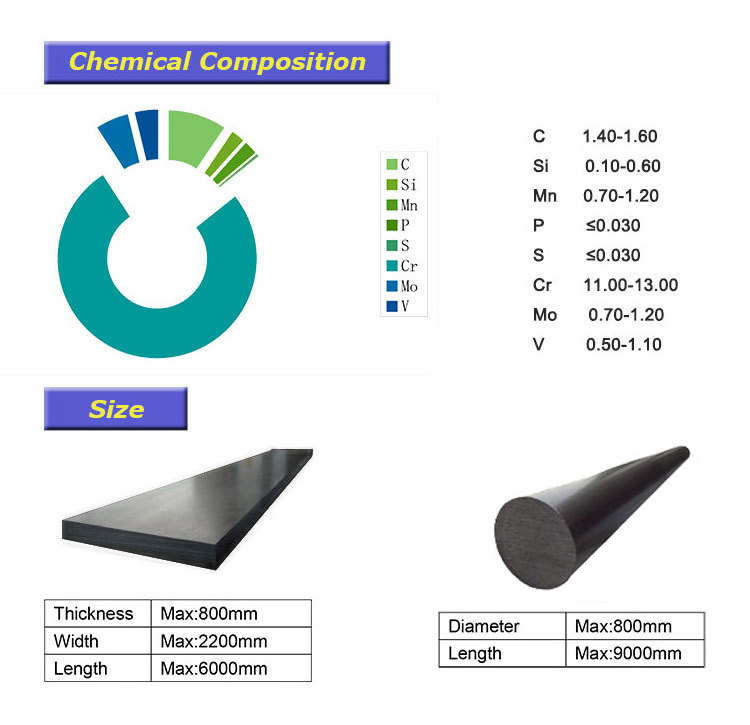

1. Chemical composition

| C | Si | Mn | P | S | Cr |

| 1.4-1.6 | 0.1-0.6 | 0.1-0.6 | ≤0.03 | ≤0.030 | 11-13 |

2. Equivalent Steel Grade

| DIN | ASTM | GB | JIS | TOCT | BS |

|

1.2379 |

D2 | Cr12Mo1V1 | SKD10 |

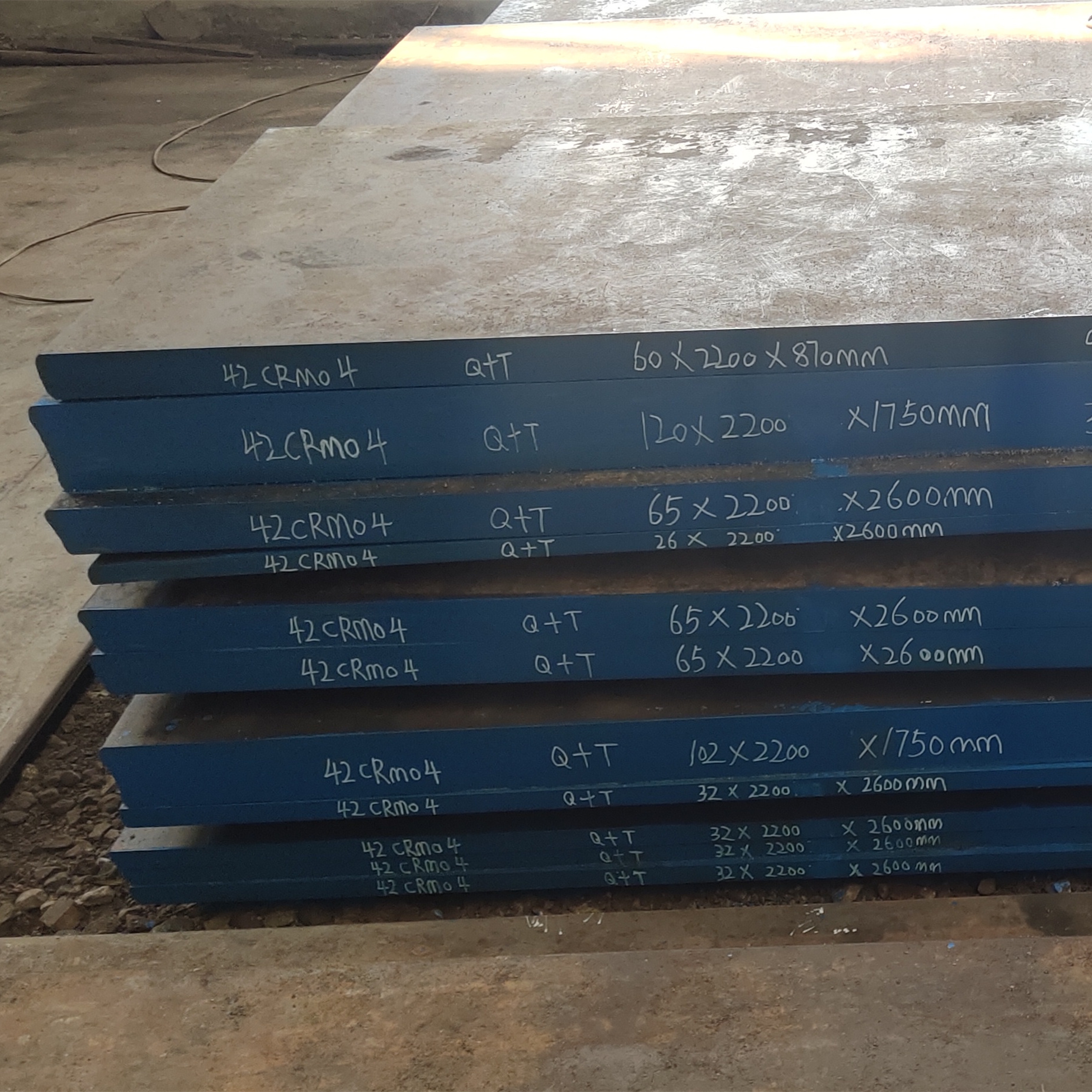

Product Show

3. Surface Treatment

Bar: Turned /Peeled

4. Size

Round bar: Diameter50-70mm; 80-120 MM ...

Length(mm) 3000-5800mm

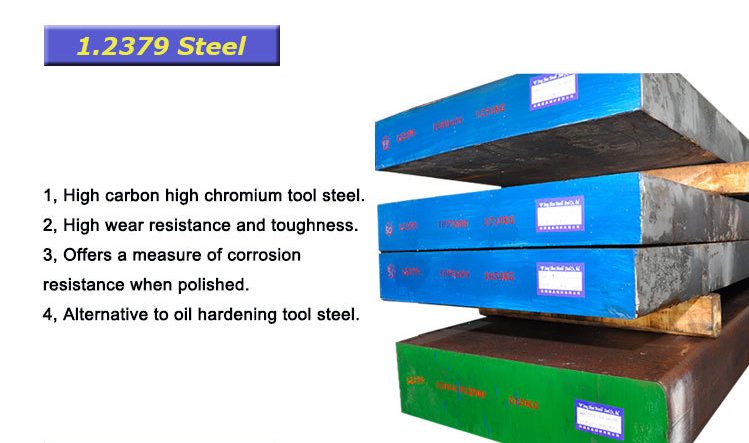

AISI D2/DIN 1.2379 Introduction:

D2 steel is an air-hardening, high-carbon, high-chromium tool steel. It has high wear and abrasion-resistant properties. It is heat treatable and machinable in annealed conditions. D2 steel shows little distortion on correct hardening. D2 steel’s high chromium content gives it mild corrosion-resisting properties in hardened conditions.

5. Fabrication and Heat Treatment

Heat Treatment

D2 steels should be preheated very slowly to 815ºC (1500ºF) and then the temperature can be increased to 1010ºC (1850ºF). They are then held at 1010ºC (1850ºF) for 20 to 45 minutes and air-cooled (air quenched).

Forging

Forging of D2 steels can be done from 1065ºC (1950ºF) down to 954ºC (1750ºF). Do not forge below 926ºC (1700ºF).

Annealing

Annealing of D2 steels should be done at 871 to 898ºC (1600 to 1650ºF) followed by slow furnace cooling at 4.4ºC (40ºF) per hour or less.

Tempering

D2 steels can be tempered at 204ºC (400ºF) for achieving a Rockwell C hardness of 61 and at 537ºC (1000ºF) for a Rockwell C hardness of 54.

Applications

D2 tool steels are used for long-run tooling applications, where wear resistance is important, such as blanking or forming dies and thread rolling dies.

6. Applications

For pounch mold, knife mold, screw mold, chinaware mold .

7. PACKING

8. CONTACT PERSON