Spindle unit from 612 to 1824 spindles,prolonged by unit every 36 spindles each. NEW TYPE OVER-PROLONGATION FRAME One-piece intermediate frame,and high-precision spindle rail can meet the requirement of high speed spinning.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGDA

-

Dimension(L*W*H):

-

20300 x1150 x 2315 mm

-

Weight:

-

9000 KG

-

Power:

-

25KW

-

Number of Spindle:

-

from 612 to 1824 spindles

-

Yarn Count:

-

6-12Ne

-

Spinning Equipment:

-

ring spinning frames

-

Output:

-

300-700kg/h

-

Tube inserting rale:

-

100%

-

twisting type:

-

by electronic twisting

-

Auto doffing times:

-

3 minutes

-

Spindle speed r/min:

-

12000-25000(mechanical speed with inverter)

-

Suitable for fiber length:

-

less than 40mm,40-51mm.51-60mm

-

Lifting type of ring plate:

-

by electronic lifting

Quick Details

-

Marketing Type:

-

New Product

-

Application:

-

spinning yarn

-

Production Capacity:

-

99.9%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGDA

-

Dimension(L*W*H):

-

20300 x1150 x 2315 mm

-

Weight:

-

9000 KG

-

Power:

-

25KW

-

Number of Spindle:

-

from 612 to 1824 spindles

-

Yarn Count:

-

6-12Ne

-

Spinning Equipment:

-

ring spinning frames

-

Output:

-

300-700kg/h

-

Tube inserting rale:

-

100%

-

twisting type:

-

by electronic twisting

-

Auto doffing times:

-

3 minutes

-

Spindle speed r/min:

-

12000-25000(mechanical speed with inverter)

-

Suitable for fiber length:

-

less than 40mm,40-51mm.51-60mm

-

Lifting type of ring plate:

-

by electronic lifting

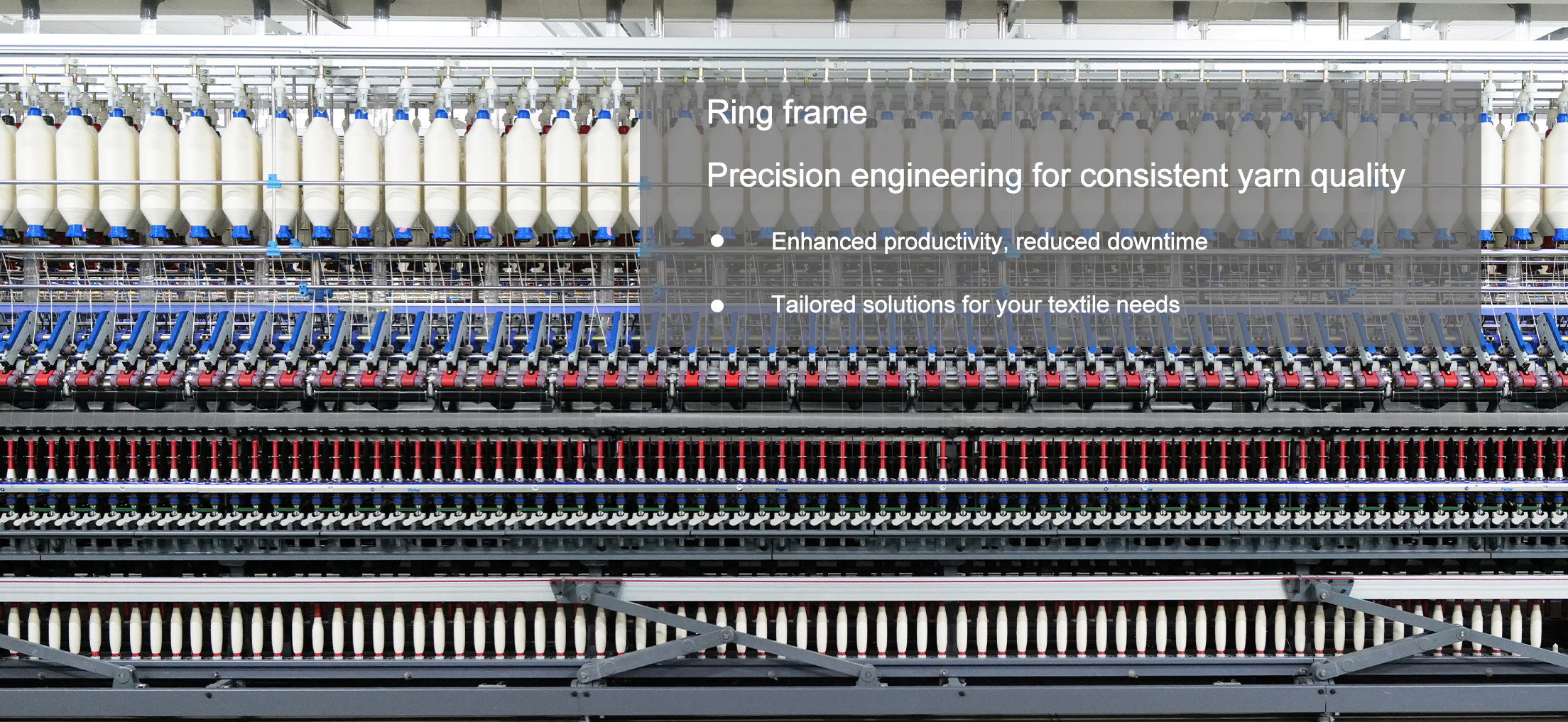

Product display and advantages

Main Feature

Ring spinning machine FA1569 boasts quick installation, doffing, and dual suction technologies at both the headstock and

tailstock. It also features intelligent spinning, reducing energy consumption by 10% compared to current rings. This series of super long ring spinning frames caters to customer demands for long, automated, easy-to-control, and labor-saving equipment,specially designed for high-quality production.

tailstock. It also features intelligent spinning, reducing energy consumption by 10% compared to current rings. This series of super long ring spinning frames caters to customer demands for long, automated, easy-to-control, and labor-saving equipment,specially designed for high-quality production.

·

Higher Performance Ring Spinning Machine Since 1952 From TONGDA China

· Lasted technology-Electric Cam system for lifting & Oil bathgear system for driving.

· High Speed & Low Power consumption 16 Steps Inverter drive system

· Machine Speed up to12000-25000 RPM

· Higher CSP & Low IPI Efficiency up to 90-93% Nos Of Spindles: 612-1824

· High Quality Precession & Fittings For Smoothly Operationwith low Noisy

· Lasted technology-Electric Cam system for lifting & Oil bathgear system for driving.

· High Speed & Low Power consumption 16 Steps Inverter drive system

· Machine Speed up to12000-25000 RPM

· Higher CSP & Low IPI Efficiency up to 90-93% Nos Of Spindles: 612-1824

· High Quality Precession & Fittings For Smoothly Operationwith low Noisy

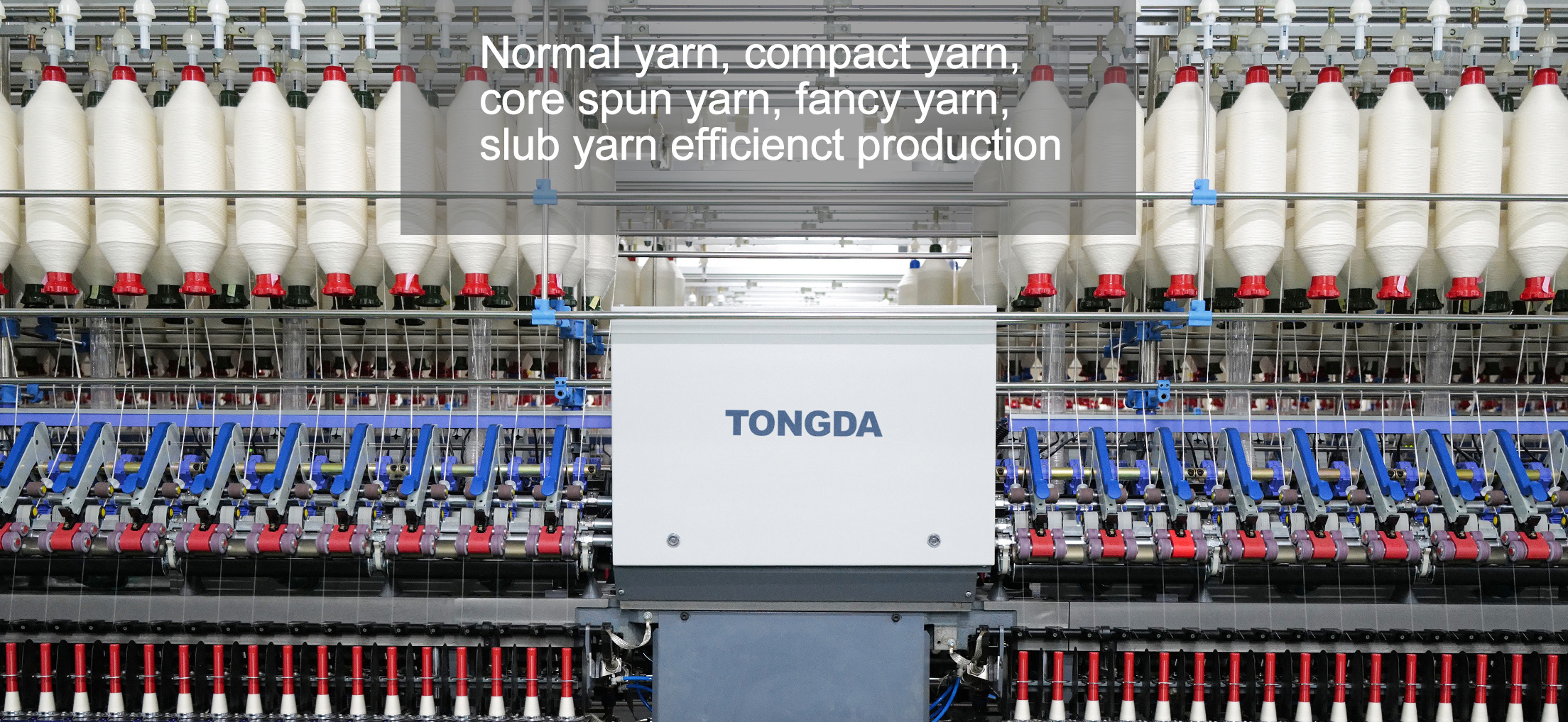

Product details

SUPER LONG

QUICK-INSTALLING TECHNOLOGY

Quick-installing can be realized by positioned pin and hole. ADJUSTMENT FREE FOR COLUMN OF RING LIFT IT IS A DOMESTIC INNOVATION DUAL-SUCTIONING AT BOTH HEADSTOCK AND TAILSTOCK

NEW TYPE OVER-PRSYNCHRONIZING TECHNOLOGYFOR INTERMEDIATE DRIVE FOR BOTTOM ROLLEROLONGATION FRAME

To be suitable for spinning different category of yarns. QUICK-DOFFING TECHNOLOGY Doffing duration 3 mins

ELECTRONIC DRAFTING SYSTEMIS PRECISE AND STABLE

Adopt high-precision controlling technology,it has the same precise level with mechanical transmission system; Bottom rollers can

be stopped first, then started in order to improve the auto-doffing performance with less end-breaks INTELLIGENT SPINNING EXPERT SYSTEM Yarn data can be stored,standard design for u-shape connection, failure illustrated on screen

be stopped first, then started in order to improve the auto-doffing performance with less end-breaks INTELLIGENT SPINNING EXPERT SYSTEM Yarn data can be stored,standard design for u-shape connection, failure illustrated on screen

High Speed Package

The highest speed for ring spinning equipped with TONGDA TD8100 Spindle, Bearing steel ring cup PG1-3854, TONGDA super light

bobbin spindle speed can reach 25000 rpm plus Production capacity increasing 10% More Energy consumption will be reduced by 7%-10% Low noise level which is 3-5dB lower than othermachines

bobbin spindle speed can reach 25000 rpm plus Production capacity increasing 10% More Energy consumption will be reduced by 7%-10% Low noise level which is 3-5dB lower than othermachines

Inside the spindle

1.Due to special double elasticity structure design, under high-speed spinning conditions, the spindle tube has multi-level shock-absorbing and noise-reducing functions.

2.Multi-level shock absorption can effectively reduce the pressure on the bearings and extend life time of the spindles, under high-speed spinning conditions.

3.Under the same working conditions, compare with other types of spindles, energy consumption is reduced by 7%-10% with TD8100.

4.At a mechanical speed of 25,000rpm, after testing,the noise of this spindle is 3-5dB lower than other type of spindles.

5. Spindle wharve diameters are available in various specifications: 18.5, 19, 19.5, 20.5

6. Equipped with suitable packages, spindle speed can reach 25000 rpm Plus.

7. Can be equipped with new model yarn grippers.

8. A special sealing structure(patent) is installed with high-quality lubricating oil, and the oil changing cycle is more than 12 months.

Main Technical Data

|

Spindle gauge

|

70

|

|

Spindle number

|

from 612-1824.expanded by unit 36 spindles each

|

|

Roller

|

Φ27XΦ27XΦ27orΦ27XΦ30XΦ27 box length 6 spindles

|

|

Lift

|

160,180(with aluminum spindle)

|

|

Ring diameter mm

|

38,40,42,45(PG type)

|

|

Suitable for fiber length

|

less than 40mm,40-51mm.51-60mm

|

|

Suitable for yarn density Tex(Ne)

|

36.4-4.86(16-120)

|

|

Suitable for Twist(turns per meter)

|

230-3000(Wharf diameter 19)

|

|

Twist direction

|

Z with singletension disc,Z and S with dual tension disc

|

|

Draft

|

Total draft 10-60(standard),total draft10-80(optional)

|

|

Spindle speed r/min

|

12000-25000(mechanical speed with inverter)

|

|

Spinning driving

|

driving by disc

|

|

Drafting type

|

3-lineroller,cradle apron(short)plus bottom apron (long).top weighting

|

|

Lifting type of ring plate

|

arm by electronic lifting

|

|

Twisting type

|

by electronic twisting

|

|

Doffing type

|

Auto-doffing

|

|

Bobbin lifting rate when doffing

|

>99.5%

|

|

Tube inserting rate

|

100%

|

|

None-endbreak rate when auto-doffing finished

|

≥97%(for medium count yarn)

|

|

Auto-doffng duration

|

3 minutes

|

Why Choose Us

Regarding the package & delivery

Hot Searches