- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

600mm

-

Dimension(L*W*H):

-

325*270*270CM

-

Weight (T):

-

8 T

-

Table Travel (Z) (mm):

-

650mm

-

Positioning Accuracy (mm):

-

0.012mm

-

Repeatability (X/Y/Z) (mm):

-

0.007mm

-

Range of Spindle Speed(r.p.m):

-

4000 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5/11 kw

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 10000 mm/min

-

Rapid Feed Speed(m/min):

-

36/36/30

-

Place of Origin:

-

Ningxia, China

-

Brand Name:

-

DAHE

-

Voltage:

-

380V/220V

-

Marketing Type:

-

New Product 2022

-

Core Components:

-

Control system

-

Product name:

-

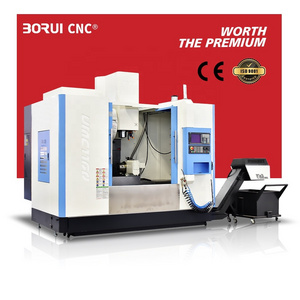

3-axis Vertical Cnc Machining Center

-

Machine Type:

-

Vertical CNC Milling Machine

-

Application:

-

General Machinery Processing

-

Product type:

-

VMC 1060 Machining Center

-

Keywords:

-

VMC1060 Vertical CNC Machining Center

-

Processing:

-

Metal Vertical Milling Machine

-

Controlling Mode:

-

Fanuc Mitsubishi Siemens Gsk System

-

Precision:

-

High Precision Machining Center

-

CNC or Not:

-

CNC Systemn

-

Function:

-

Machining Metal

Quick Details

-

Table Size (mm):

-

1300*600mm

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

1000mm

-

Table Travel (Y) (mm):

-

600mm

-

Dimension(L*W*H):

-

325*270*270CM

-

Weight (T):

-

8 T

-

Table Travel (Z) (mm):

-

650mm

-

Positioning Accuracy (mm):

-

0.012mm

-

Repeatability (X/Y/Z) (mm):

-

0.007mm

-

Range of Spindle Speed(r.p.m):

-

4000 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5/11 kw

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 10000 mm/min

-

Rapid Feed Speed(m/min):

-

36/36/30

-

Place of Origin:

-

Ningxia, China

-

Brand Name:

-

DAHE

-

Voltage:

-

380V/220V

-

Marketing Type:

-

New Product 2022

-

Core Components:

-

Control system

-

Product name:

-

3-axis Vertical Cnc Machining Center

-

Machine Type:

-

Vertical CNC Milling Machine

-

Application:

-

General Machinery Processing

-

Product type:

-

VMC 1060 Machining Center

-

Keywords:

-

VMC1060 Vertical CNC Machining Center

-

Processing:

-

Metal Vertical Milling Machine

-

Controlling Mode:

-

Fanuc Mitsubishi Siemens Gsk System

-

Precision:

-

High Precision Machining Center

-

CNC or Not:

-

CNC Systemn

-

Function:

-

Machining Metal

Specification

|

TABLE

|

Worktable size

|

mm

|

1300*600

|

|

|

T-Slot (Quantity*Width*Distance)

|

mm

|

18*5

|

|

|

Max load of worktable

|

kg

|

1000

|

|

TRAVEL

|

X/Y/Z axis travel

|

mm

|

1000/600/650

|

|

|

X/Y/Z axis guideway type

|

mm

|

Quenched cast iron, plastered construction

|

|

|

Distance from spindle center to column

|

mm

|

650

|

|

|

Distance from spindle nose to table

|

mm

|

130—780

|

|

FEED RATE

|

Rapid traverse of X/Y/Z axis

|

m/min

|

15/15/12

|

|

|

Cutting feed rate

|

mm/min

|

1~10000

|

|

SPINDLE

|

Max spindle speed

|

r/min

|

8000rpm(Two-stage gear drive)

|

|

|

Spindle taper hole (mounting diameter)

|

|

BT40mm

|

|

ATC system |

Tool magazine capacity

|

|

24T/Arm

|

|

|

Tool shank type

|

|

BT40

|

|

|

Max tool weight

|

kg

|

8

|

|

|

Max tool diameter (w/o adjacent tools)

|

mm

|

Φ80*300mm

|

|

|

Max tool length

|

mm

|

300

|

|

|

ool change time(drum/arm opt)

|

s

|

5/2.5sec

|

|

ACCURACY

|

X/Y/Z axis positioning accuracy

|

mm

|

0.012

|

|

|

X/Y/Z axis repeatability accuracy

|

mm

|

0.007

|

|

CONTROL SYSTEM

|

Controller

|

|

FANUC

|

V1060 Vertical Machining center

is Ningxia Yinchuan Dahe CNC Machine Tool Co., LTD. (formerly Dahe Machine Tool Factory) according to the characteristics of modern mold and automatic machining, the advanced automatic machining technology has been successfully applied to the machining industry in China.

Its advantage is that the advanced automatic processing technology has been successfully applied to the global machining industry, which has significantly promoted the improvement of the global machining technology level. It is widely used in the fields of mold, aerospace, aviation, ordnance, automobile and motorcycle, nuclear industry, railway and so on.

Using the machine tool can save the process equipment, shorten the production preparation period, ensure the quality of parts processing, improve the production efficiency.

Electrical system of V1060 vertical machining center:

1.

FANUC 0i MD or 0i mate MD numerical control system.

> Adopt modular structure.

> Use dedicated LSI to improve integration, reliability, size, and cost.

> A wide range of product applications. Each CNC device can be equipped with a variety of control software, suitable for a variety of machine tools.

> Adopt new processes and technologies. Surface mounting technology SMT, multilayer printed circuit board, optical fiber cable, etc.

> CNC device small size, panel assembly, built-in PMC (Programmable Machine tool controller).

> Constantly adding new features in interpolation, acceleration, compensation, automatic programming, graphical display, communication, control, and diagnostics:

1) Interpolation function: In addition to straight line, circular arc and helix interpolation, there are also imaginary axis interpolation, extreme coordinate interpolation, conical plane interpolation, exponential function interpolation, spline interpolation, etc.

2) Automatic acceleration and deceleration function of cutting feed: linear acceleration and deceleration after interpolation, and acceleration and deceleration before interpolation.

3) Compensation function: in addition to pitch error compensation and lead screw reverse clearance compensation, there are slope compensation linearity compensation and various new tool compensation functions.

4) Fault diagnosis function: artificial intelligence is adopted, and the system has reasoning software to find fault causes based on knowledge base.

> User-oriented features of CNC devices. To the user custom macro program, MMC and other functions to achieve.

> Supports multiple languages. Such as Japanese, English, German, Chinese, Italian, French, Dutch, Spanish, Swedish, Norwegian, Danish and so on.

> A variety of peripherals are available.

With: three axis linkage, helix interpolation, rigid tapping, fault diagnosis and record, tool management, overload protection, graphic display, macro program,RS232C and USB communication interface and other main functions.

2. Servo system

>

Βi

series is a kind of reliability and performance of the servo system.

The series is used for the feed shaft and spindle of machine tools, with sufficient performance and function. Through the control of servo HRV control and spindle HRV control, to achieve high speed, high precision and high efficiency control.

1) Smooth feed and fuselage design of compact servo motor

2) High resolution pulse encoder (128,000 /rev)

3) Compact body design, basic performance of the spindle motor

4) Realize the servo amplifier with the integration design of servo 3 axis + spindle 1 axis

5) SERVO, spindle control and servo debugging tool SERVO GUIDE

3. Electrical components

No contact switch, air switch, button and so on are imported famous products.

TH5656 vertical machining center installation environment:

Power supply:

AC 3 diameter 380V +10% ~ -15% 50HZ±1Hz

Air source:

Pressure 0.5 ~ 0.7Mpa, flow 250L/min

Relative humidity

: ≤80%

Ambient temperature:

5° to 40°C

Hot Searches