- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Application:

-

impact crusher

-

Installation:

-

Engineer guide

-

Colour:

-

Optional

-

Certification:

-

DIN

Quick Details

-

Weight (KG):

-

160

-

Marketing Type:

-

Hot Product 2021

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OEM

-

Application:

-

impact crusher

-

Installation:

-

Engineer guide

-

Colour:

-

Optional

-

Certification:

-

DIN

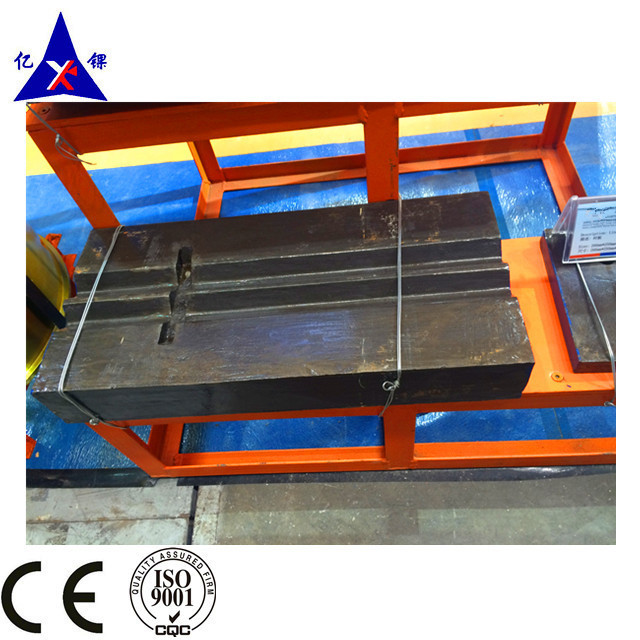

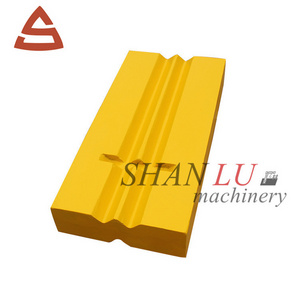

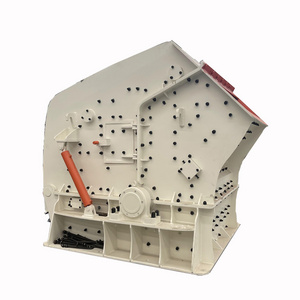

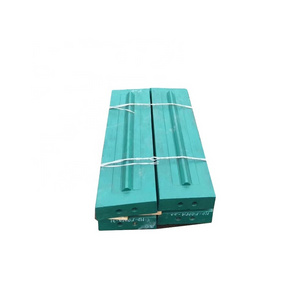

hazemag impact crusher ap4s wear parts blow bar lier plate

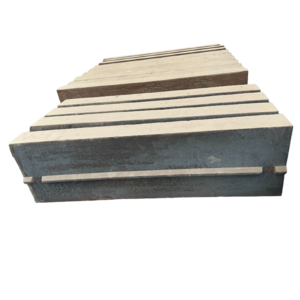

Blow bars for impact crusher(all Chinese brand blow bar and many famous brand in the world are okay )

1.Material Specifications of blow bar :

|

High Chrome Casting Material Chemical Composition(%) |

||||||||||

| Code Elem. | C | Si | Mn | Cr | Mo | Na | Cu | P | S | HRC |

| KmTBCr4Mo | 2.5-3.5 | 0.5-1.0 | 0.5-1.0 | 3.5-4.5 | 0.3-0.5 | - | - | ≤0.15 | ≤0.10 | ≥55 |

| KmTBCr9Ni5Si2 | 2.5-3.6 | 1.5-2.2 | 0.3-0.8 | 8.0-10.0 | 0-1.0 | 4.5-6.5 | 4.5-6.5 | - | - | ≥58 |

| KmTBCr15Mo | 2.8-3.5 | ≤1.0 | 0.5-1.0 | 13-18 | 0.5-3.0 | 0-1.0 | 0-1.0 | ≤1.0 | ≤0.06 | ≥58 |

| KmTBCr20Mo | 2.0-3.3 | ≤1.2 | ≤2.0 | 18-23 | ≤3.0 | ≤2.5 | ≤1.2 | - | - | ≥60 |

| KmTBCr26 | 2.3-3.3 | ≤1.2 | ≤1.0 | 23-30 | ≤3.0 | ≤2.5 | ≤2.0 | - | - | ≥60 |

2.Model: for all Chinese brand and many other OEM brand such as hazmag,hartl.etc

| Model |

Roller size

(mm) |

Feeding

opening(mm) |

Max. feed

size (mm) |

Capacity (t/h) |

Power

(kw) |

Weight (t) | |

| PF-1007 | Φ 1000x700 | 400x730 | 300 | 35~50 | 55 | 9.5 | |

| PF-1010 | Φ 1000x1050 | 400x1080 | 350 | 50~80 | 75 | 10 | |

| PF-1010V | Φ 1000x1050 | 400x1080 | 350 | 50-80 | 55-75 | 13.2 | |

| PF-1210 | Φ 1250x1050 | 400x1080 | 350 | 70~120 | 110 | 14 | |

| PF-1210V | Φ 1250x1050 | 400x1080 | 350 | 70-120 | 110-132 | 15.2 | |

| PF-1214 | Φ 1250x1400 | 400x1430 | 350 | 80~160 | 132 | 18 | |

| PF-1214V | Φ 1250x1400 | 400x1080 | 350 | 130-180 | 132-160 | 20 | |

| PF-1315 | Φ 1300x1500 | 860x1520 | 500 | 160~260 | 200 | 19.3 | |

| PF-1315V | Φ 1320x1500 | 860x1520 | 500 | 150-220 | 180-220 | 20.5 | |

| PF-1316 | Φ 1300x1600 | 860x1520 | 500 | 170~270 | 200 | 19.5 | |

| PF-1516 | Φ 1500x1600 | 860x1580 | 500 | 240~290 | 280 | 26.5 |

3.World Most Popular Blow Bar Feature

- Emply the external refining technology, effectively reduced the harmful elements, impurity and oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel.

- Using proprietary metamorphic agent for modification treatment, fine grains, improve carbide configuration and distribution, and to improves the abrasion resistance and tenacity.

- Optimizing heat treatment process, make the product of uniform hardness especially, impact abrasion resistance becoming stronger.

-

Manufactured with hypereutectic super high chromium, our blow bar has a service life 50~100% longer than those made of traditional high chromium iron. The special processing techniques ensure that our flat hammer has leading performance.

4 . More crusher spare parts:

Shanghai Yike Road & Bridge Machinery Co., Ltd supply all kinds of good quality crusher spare parts for many Chinese brand and meto,telsmith,hartl etc

4.1Jaw crusher parts:

jaw plate(jaw liner) , toggle plate, up guard plate, down guard plate, set adjustment, tension rod,toggle gasket, spring, tension rod,eccentric shaft,end cover, block, moving jaw, frame, spring, bolt and nuts,washer.

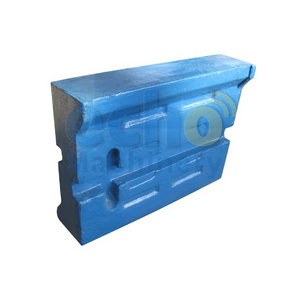

4.2 Impact crusher parts:

Blow bar(flat hammer) ,adjustment bar, impact plate,liner plate, frame(impact rack), cover,,bolts,nuts, washer,etc

Beijing Sino-Aero Construction Engineering Company Limited is one of member companies of China Aviation Suppliers Holding Company and one of major contractors in China civil aviation airport construction, including airfield construction, airfield lighting installation, machinery&electrical equipment, and information and control system installation in terminal area, as well as air traffic control system installation.

In recent years, the Company has completed more than 430 projects for over 60 major airports in Beijing, Shanghai, Guangzhou, Tianjin, Shenzhen, Kunming, Shenyang, Hangzhou, Wuhan, Changsha, Chengdu, Chongqing, Xi’an and etc., emergency projects for airports in Lhasa and Yushu, as well as those for airports in Sudan, Togo and Angola. Many of those projects won top engineering awards in China.

The Company has devoted itself to developing new techniques and materials for providing better quality and more cost effective engineering solutions for airfield construction. Slip-form concreting technique applied in concrete runway construction sets a good example of such. While technique for runway resurface with asphalt concrete overlay without interruption of flight operation, as the other example, makes an impossible otherwise and cost effective solution for runway ‘face lifting’ for those busy airports. The Company has also developed IT Operation Management System for civil aviation airport.

The Company aims to provide with its professional engineering solutions and the best service to a total satisfaction of the clients.