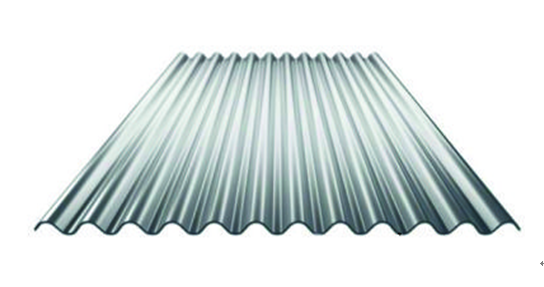

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Liaoning, China

-

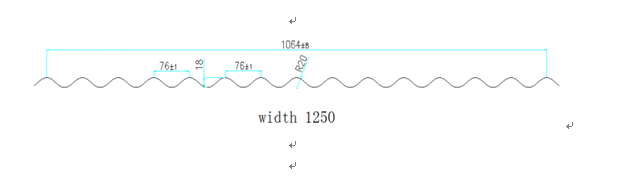

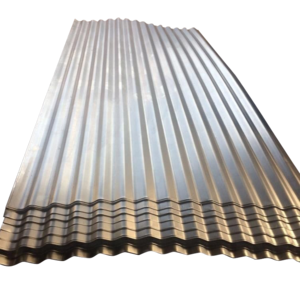

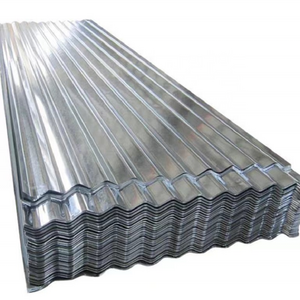

Product name:

-

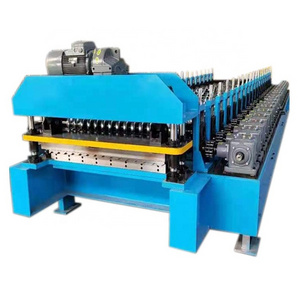

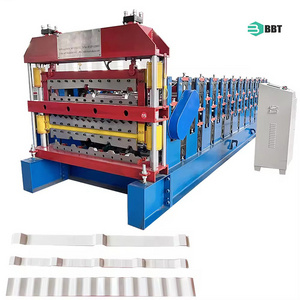

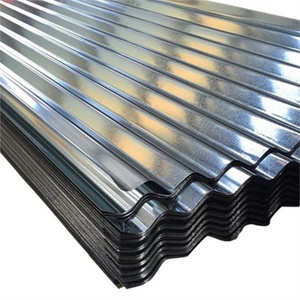

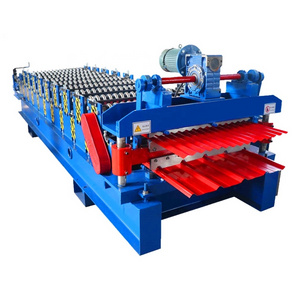

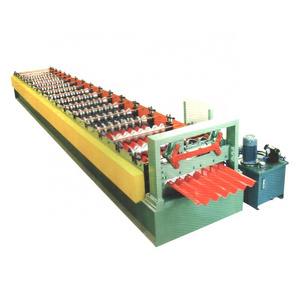

eva foam corrugated iron zinc roofing sheet making machine

-

Cutting blade material:

-

Cr12

-

motor powerof forming machine:

-

5.5KW

-

Hydraulic station motor:

-

3.0 KW, pressure: 8-12Mpa

-

Forming machine type:

-

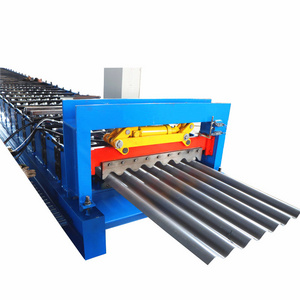

wallboard and chain drive

-

Roller material:

-

superior 45# steel forging

-

Thickness of Chrome plated on roller:

-

0.05mm

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-10m/min

-

Place of Origin:

-

Liaoning, China

-

Product name:

-

eva foam corrugated iron zinc roofing sheet making machine

-

Cutting blade material:

-

Cr12

-

motor powerof forming machine:

-

5.5KW

-

Hydraulic station motor:

-

3.0 KW, pressure: 8-12Mpa

-

Forming machine type:

-

wallboard and chain drive

-

Roller material:

-

superior 45# steel forging

-

Thickness of Chrome plated on roller:

-

0.05mm

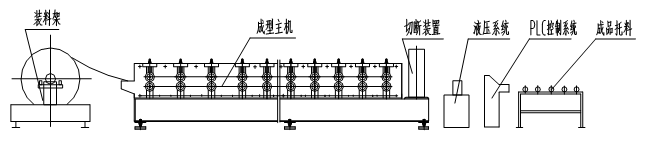

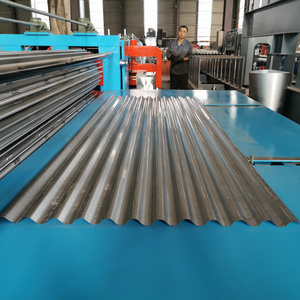

Normal manual De-coiler (5T); Main machine of roll forming; Hydraulic forming cutting; Hydraulic station; PLC computer operation cabinet; Run-out table

Production process

Passively de-coiling → Guiding & Feeding material → Roll Forming → Cutting-to-length → Output panel

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

During the Production

* We will send photo of making machine process detail every once in a while.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Delivery time:

30 working days since receiving buyer's 30% down payment

Payment term:

T/T( 30%TT in advanced, 70%TT before the machine shipped).

Guarantee period:

13 months since the date of B/L.

HS Code:

84552210

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: 7 days if the goods are in stock. or it is 30 days if the goods are not in stock.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment. or 100% L/C

If you have another question, pls feel free to contact us as below: