- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

Fast

-

Dimension(L*W*H):

-

2800*2100*1200mm

-

Power:

-

12kw

-

Weight (KG):

-

2000

-

Product name:

-

Asphalt curb machine road concrete curb machine

-

Machine type:

-

Asphalt Road Construction Machines

-

Function:

-

curb making machine

-

Key words:

-

curb stone making machine

-

Keywords:

-

curb machine for landscaping

-

Usage:

-

Green Belt

-

Aplication:

-

highway guardrail cold roll forming machine

-

Name:

-

concrete curb machine garden

-

Quality:

-

High Guarantee

-

After-sales:

-

Oneline

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YG

-

Features:

-

Easy opration

-

Production Capacity:

-

Fast

-

Dimension(L*W*H):

-

2800*2100*1200mm

-

Power:

-

12kw

-

Weight (KG):

-

2000

-

Product name:

-

Asphalt curb machine road concrete curb machine

-

Machine type:

-

Asphalt Road Construction Machines

-

Function:

-

curb making machine

-

Key words:

-

curb stone making machine

-

Keywords:

-

curb machine for landscaping

-

Usage:

-

Green Belt

-

Aplication:

-

highway guardrail cold roll forming machine

-

Name:

-

concrete curb machine garden

-

Quality:

-

High Guarantee

-

After-sales:

-

Oneline

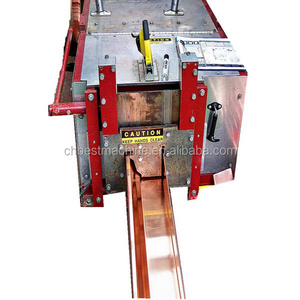

Road concrete curb paver machine curb and gutter machine curb making machine

Concrete curb and gutter machine is a one-time completion of the whole process of laying curbs in site pouring construction, which can improve work efficiency and reduce labor intensity. Plastic concrete can also be used as dry hard concrete. After being compacted by a motor, it is formed by a sliding mold and vibrated continuously while walking. The formed curb has higher impact strength and stability.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Specifications

|

|

1

|

Paving curb size

|

width <900mm, height <500mm, customized size is available

|

|

2

|

Vibrating rod forming

|

suitable for plastic concrete (higher strength of curbs); suitable for dry hard concrete (more beautiful appearance of curbs)

|

|

3

|

Automatic leveling(optional)

|

leveling range: +-5cm (Japanese components, temperature compensation, overvoltage and overcurrent protection)

|

|

4

|

Automatic steering

|

Minimum turning radius: 3.5m (Japanese components, temperature compensation, overvoltage and overcurrent protection)

|

|

5

|

Paving speed

|

1-6m/min (using CVT transmission, convenient to adjust the most suitable paving speed)

|

Working principle:

Spiral blades are installed in front of the forming mold, and the blades continuously rotate to continuously push the cement concrete into the forming mold and squeeze out the curb. The vibrating rod is installed in front of the forming mold. The high-frequency vibration of the rod makes the cement concrete reach a certain degree of compactness, and the machine advances by its own power.

Spiral blades are installed in front of the forming mold, and the blades continuously rotate to continuously push the cement concrete into the forming mold and squeeze out the curb. The vibrating rod is installed in front of the forming mold. The high-frequency vibration of the rod makes the cement concrete reach a certain degree of compactness, and the machine advances by its own power.

Product Overview

Product Packaging

Hot Searches