Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

15 kN

-

Theoretical Shot Volume(cm³):

-

97 cm³

-

Injection Rate (g/s):

-

53 g/s

-

Injection Weight (g):

-

89 g

-

Screw diameter (mm):

-

32 mm

-

Distance between Tie Bars:

-

110*110mm

-

Weight (KG):

-

2000

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

BOBO-ZJ

-

Brand Name:

-

BOBO

-

Power (kW):

-

5.5 kW

-

Power supply:

-

380V/50Hz

-

Installed power:

-

23 kW

-

Actual power consumption:

-

12kw/h

-

Air supply:

-

0.6MPa

-

Air consumption:

-

0.6 m3/min

-

Production speed:

-

≥100 pieces/minute

-

Tube diameter:

-

16~50mm

-

Applicable tube:

-

PE laminated and PE tubes

-

Machine dimensions:

-

3.2*3.1*2.3m

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2020

Quick Details

-

Plasticizing Capacity(g/s):

-

53

-

Mold Height(mm):

-

150 - 200 mm

-

Ejector Stroke(mm):

-

200 mm

-

Ejector Force(kN):

-

15 kN

-

Theoretical Shot Volume(cm³):

-

97 cm³

-

Injection Rate (g/s):

-

53 g/s

-

Injection Weight (g):

-

89 g

-

Screw diameter (mm):

-

32 mm

-

Distance between Tie Bars:

-

110*110mm

-

Weight (KG):

-

2000

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

420 mm

-

Model Number:

-

BOBO-ZJ

-

Brand Name:

-

BOBO

-

Power (kW):

-

5.5 kW

-

Power supply:

-

380V/50Hz

-

Installed power:

-

23 kW

-

Actual power consumption:

-

12kw/h

-

Air supply:

-

0.6MPa

-

Air consumption:

-

0.6 m3/min

-

Production speed:

-

≥100 pieces/minute

-

Tube diameter:

-

16~50mm

-

Applicable tube:

-

PE laminated and PE tubes

-

Machine dimensions:

-

3.2*3.1*2.3m

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2020

Product Description

Summary

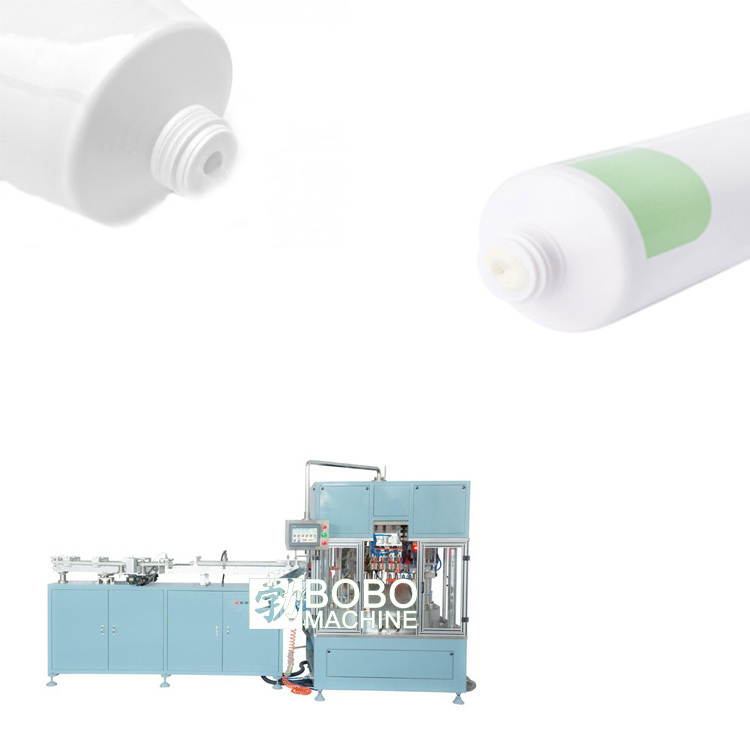

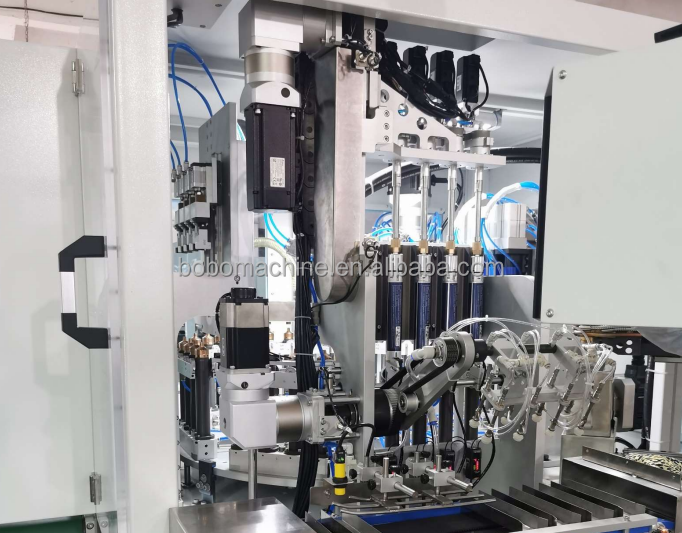

This machine is composed of gap index positioning device, tube feeding device, plastic injection device, shoulder forming device, cooling device, tube discharge device, automatic control system, etc. The tube feeding device consists of a tube distribution mechanism connecting with the tube body making machine, tube-feeding manipulators, and fixed or color code aligning positioning device. With the integration of mechanism, electric, pneumatics and IOT (The Internet of Things)communication, it is a high-speed tube shoulder injection machine which completely realizes intelligent control.

Specification

|

Power supply

|

380V/50Hz

|

|

Installed power

|

23 kW(including heater power: 11 kW)

|

|

Actual power consumption

|

12kw/h

|

|

Air supply

|

0.6MPa

|

|

Air consumption

|

0.6 m3/min

|

|

Production speed

|

≥100pieces/minute

|

|

Tube diameter

|

∅16~∅50mm

|

|

Applicable tube

|

laminated and PE tubes

|

|

Machine dimensions

|

3.2×3.1×2.3m(L×W×H)

|

|

Machine weight

|

3tons

|

Packing and Shipping

Packaging:

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

About Us

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Hot Searches