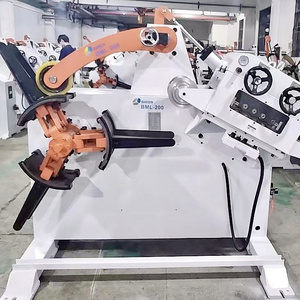

Decoiler/uncoiler, straightener, NC servo roll feeder, 3 in 1.

Saving space in work shop.

Full automatic feeding.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Optional

-

Dimension(L*W*H):

-

Customization

-

Weight (KG):

-

7000

-

Certification:

-

CE Certificate

-

Usage:

-

Metal Sheet Strip Coil

-

uncoiler/decoiler:

-

decoil metal strip coil

-

straightener/leveller:

-

flatten metal strip

-

feeder:

-

clamp and feed metal strip forward

-

feeder motor type:

-

servo motor

-

PLC control:

-

full autoamtic

-

Material thickness:

-

0.4-3.2mm

-

Feed speed:

-

20mm/min

-

Item:

-

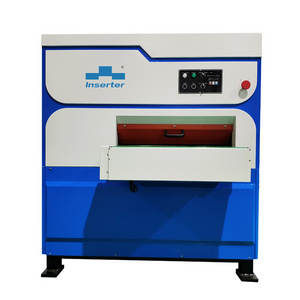

NC servo roll feeding machine

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIHAO or OEM

-

Voltage:

-

380V or Optional

-

Power:

-

Optional

-

Dimension(L*W*H):

-

Customization

-

Weight (KG):

-

7000

-

Certification:

-

CE Certificate

-

Usage:

-

Metal Sheet Strip Coil

-

uncoiler/decoiler:

-

decoil metal strip coil

-

straightener/leveller:

-

flatten metal strip

-

feeder:

-

clamp and feed metal strip forward

-

feeder motor type:

-

servo motor

-

PLC control:

-

full autoamtic

-

Material thickness:

-

0.4-3.2mm

-

Feed speed:

-

20mm/min

-

Item:

-

NC servo roll feeding machine

Product Application

1. This big machine combines uncoiler function, straightener function, NC servo roll feeder function together, so as 3 in 1feeder.

2. It can decoil suitable metal stript coil, then straighten the metal strip, then feed the metal strip to press machine automatically, for automatic stamping processing.

Main Features

1. Flexible operation:

All the functions of the feeder are centered on the PLC and a hand-held knob. The operator can implement all the motion functions of the equipment at one location. This can save time.

2. High efficiency, strong security:

To maximize the use of mechanical action instead of manual operation.Reduce unnecessary auxiliary time, improve work efficiency. Powerful auxiliary function, so that the operator can stay away from the uncoiler。

3. Easy to operate:

According to user needs, you can switch between the press or the device to control. Improve the equipment to adapt to the scope for the customer to save costs.

4. Area is reasonable:

Li Hao NCMF series is the powerful also have the most reasonable size in the industry, we can save space occupancy costs for the customers.

5. Control system compatibility:

NCMF series using a full set of Japan's Mitsubishi control system, and the standard system at home and abroad compatible, users do not need to worry about data conversion and other issues can be directly used to operate.

6. The design is harmonious and reasonable:

Li Hao’s NCMF series is the first on the industry to introduce industrial design into product. Li Hao and the most well-known industrial design cooperation, while ensuring the basic performance of equipment at the same time, maximize the visibility of the equipment to improve the operational comfort.

|

Basic parameters

|

|

|

|

|

||||

|

Name

|

Uncoiler, straightener, NC servo roll feeder, 3 in 1

(including hydraulic expansion, coil car)

|

|

|

|

||||

|

Model

|

NCMF-400B

|

NCMF-600B

|

NCMF-800B

|

NCMF-1000B

|

||||

|

Width of the material

|

50mm~400mm

|

50mm~600mm

|

50mm~800mm

|

50mm~1000mm

|

||||

|

Thickness of the material

|

0.4mm~3.2mm

|

|

|

|

||||

|

Straightening capacity (σs≤250MPa)

|

400×1.0mm

400×1.2mm 400×1.6mm 360×2.0mm 300×2.3mm 230×2.5mm 150×2.8mm 110×3.2mm |

600×1.0mm

600×1.2mm 400×1.6mm 360×2.0mm 300×2.3mm 230×2.5mm 150×2.8mm 110×3.2mm |

800×1.0mm

600×1.2mm 400×1.6mm 360×2.0mm 300×2.3mm 230×2.5mm 150×2.8mm 110×3.2mm |

1000×0.8mm

800×1.0mm 600×1.2mm 400×1.6mm 360×2.0mm 300×2.3mm 230×2.5mm 150×2.8mm 110×3.2mm |

||||

|

Coil inside diameter

|

Φ460mm~Φ530mm

|

|

|

|

||||

|

Max.coil outside diameter

|

Φ1400mm

|

|

|

|

||||

|

Max.coil weight

|

5000KG

|

|

|

7000KG

|

||||

|

Straightening roll diameter

|

Φ64mm×9(up 5/down 4)

|

|

|

|

||||

|

Material of straightening roll

|

GCr15(HRC58-62)

|

|

|

|

||||

|

Feeding roll diameter

|

Φ84mm

|

|

|

|

||||

|

Decoiler power

|

2.2Kw

|

|

|

3.7Kw

|

||||

|

Straightening power

|

2.9Kw

|

4.4Kw

|

|

5.5Kw

|

||||

|

Feeding speed

|

0~20m/min

|

|

|

|

||||

|

Feeding precision

|

<±0.2mm

|

|

|

|

||||

|

Other configuration

|

|

|

|

|

||||

|

Straightening adjustment type

|

Eccentric shaft adjust by worm and gear

|

|

|

|

||||

|

Load material type

|

coil car

|

|

|

|

||||

|

Feed discharging line adjustment method

|

Electric

|

|

|

|

||||

|

Press material for decoiling part

|

By pneumatic

|

|

|

|

||||

|

Feeding guide arc drivemode

|

By pneumatic

|

|

|

|

||||

|

Block arm drive mode

|

Manual

|

|

|

|

||||

|

Front block arm opening and closing method

|

Pneumatic

|

|

|

|

||||

|

Feeding device movement mode

|

Two-way screw hands

|

|

|

|

||||

|

Operation control mode

|

Main control cabinet + action unit remote control switch

|

|

|

|

||||

|

Tail of material detector

|

Exist

|

|

|

|

||||

|

Purchased parts brand

|

|

|

|

|

||||

|

Main bearing

|

HRB,ZWZ

|

|

|

|

||||

|

Servo motor

|

Japan YASKAWA(SGMGH)

|

|

|

|

||||

|

Man-machine interface

|

Taiwan WEINVIEW(Colored)

|

|

|

|

||||

|

Common motor

|

Taiwan Wanxin

|

|

|

|

||||

|

Frequency changer

|

Taiwan DELTA

|

|

|

|

||||

|

Pneumatic unit

|

Taiwan Airtac

|

|

|

|

||||

|

PLC

|

Japan Mitsubishi

|

|

|

|

||||

|

Relay

|

Japan Omron

|

|

|

|

||||

|

Hydraulic fittings

|

Guangdong Lishiyuan

|

|

|

|

||||

|

Other technical data

|

|

|

|

|

||||

|

Pneumatic pressure

|

0.5Mpa

|

|

|

|

||||

|

Hydraulic pressure

|

7Mpa

|

|

|

|

||||

|

voltage

|

3phase 380V

|

|

|

|

||||

|

Feeding line height

|

1050mm-1250mm

|

|

|

|

||||

|

Input material type

|

From down to up

|

|

|

|

||||

|

Standard direction

|

From left to right, or from right to left.

|

|

|

|

||||

|

Equipment length

|

≈4.5m

|

|

|

|

||||

Decoiler straightener feeder, 3 in 1

Mandrel of uncoiler

Four pieces of plates.

Each plate is fixed by screws very well.

Cantilever type.

Round mandrel of uncoiler

Automatic expansion, by hydraulic cylinder drive.

Full round, for better loading.

Ruler at plate of mandrel

It can indicate width of coil material.

Ruler at plate of mandrel

..., 400, 300, 200, 100, 0 | 0, 100, 200, 300, 400, ...

User can put coil material at center line position of this machine very easiliy.

Arm shape pressing device.

Drived by pneumatic cylinder or hydraulic cylinder.

Coil material will not become loosed.

Retainers of uncoiler

They can keep coil material at center line position.

Easy to use.

Motor for hydraulic pump.

Powerful AC motor make sure of hydraulic pressure.

Cooling system is optional.

Motor for uncoiler

Powerful AC motor is adopted.

Cover is adopted to protect the motor.

Hydraulic cylinder for uncoiler

Hydraulic cylinder drives for automatic expansion, for mandrel of uncoiler.

Cover is adopted to protect it.

Guiding device for straigntener and feeder

While uncoiler decoil coil material, so material can get into entrance of feeder easily.

Entrance of straightener and feeder

Guiding device, let material at center line position.

Good design, safe and easy to use.

HMI controller

Touch screen and buttons.

User touch numbers and input feeding length numbers.

User touch order menu for the machine.

Dial gauge for straightener

Straightener has upper staightening rollers and lower straightening rollers.

As per various thickness of coil material, user need to adjust distance between upper rollers and lower rollers.

With the dial gauge, user can adjsut distance easily.

Gear set of straightener and feeder

Precise gear set is adopted, for high speed and high precision feeding.

Discharge exit of feeder

Rollers, limiting stopper, etc, are adopted for straight feeding also.