- Product Details

- {{item.text}}

Quick Details

-

Power:

-

170kw

-

Dimension(L*W*H):

-

Based

-

Weight:

-

15 kg, Based on design

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

75m3/h concrete batching plant for sale

-

Discharging Height:

-

3.8m

-

Color:

-

Customer Request

-

Capacity:

-

75m3 /h

-

Application:

-

Construction Projects

Quick Details

-

Machine Type:

-

Production line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Conele

-

Power:

-

170kw

-

Dimension(L*W*H):

-

Based

-

Weight:

-

15 kg, Based on design

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

75m3/h concrete batching plant for sale

-

Discharging Height:

-

3.8m

-

Color:

-

Customer Request

-

Capacity:

-

75m3 /h

-

Application:

-

Construction Projects

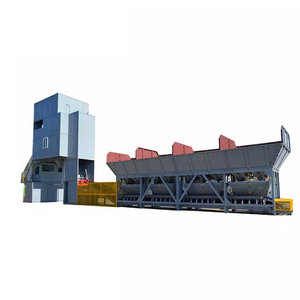

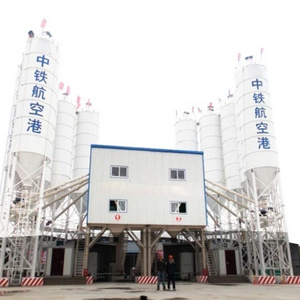

75m3/h Mobile concrete batching plant for sale, mobile concrete plant price

ready concrete batching plant is mainly composed 0f PLD batching machine, twin shaft concrete mixer or CMP planetary concrete mixer ,cement silos, automatic computer control system, electronic weighing, screw conveyor and others.It can mix fluidity concrete, plastic concrete, hard concrete and other proportioning concrete.

| Concrete Batching Plant | ||||||

| Model | HZS25 | HZS35 | HZS60 | HZS90 | HZS120 | HZS180 |

| Productivity (m³/h) | 25 | 35 | 60 | 90 | 120 | 180 |

| Discharge Height (mm) |

3800 |

3800 | 4000 | 4200 | 4200 | 4200 |

| Mixer Model | JS500 | JS750 | JS1000 | JS1500 | JS2000 | JS3000 |

| Working Cycle Time (s) | 72 | 72 | 60 | 60 | 60 | 60 |

| Batching Machine Model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Affregate Number | 3 | 3 | 4 | 4 | 4 | 4 |

| Max.Aggregate Size (pebble/gravel) | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm |

| Aggregate Weighing Accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement Weighing Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Water Supply Weighing Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Admixtures Weighing Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Note: Any change of technical data shall not be advised additionally. | ||||||

Application

The Fixed Concrete Batching Plant can be used for industry, construction, road, railway, bridge, water conservation, ports, and so on.

Prefabricated parts:

Cement pipe,

Block brick

Subway tube

Pipe pile

Pavement brick

Wall panel

Main parts

Planetary concrete mixer

Twin shaft concrete mixer

Aggregate batching machine

Control system

Screw conveyor

Features of belt conveyor concrete batching plant

Combining our domestic costruction situation, we designed the belt conveyor concrete batching plant. It adopts the world popular quick installation modular structure, efficient imported concrete mixer, computerized controlled system and environment friendly design. this series of concrete batching plant is mainly used for porjects like bridge, water conservancy, airport, dock and premixed concrete product factories where large quantity of concrete is needed.

Aggregates batcher

1. The batcher,with 3-5 aggregate hoppers,can be designed as per customer’s requirements. There are independent weighing hoppers and belt conveyor under the aggregate hoppers that could be designed as steel structure type, underground and half-underground types. the aggregates can be fed into the aggregate hoppers by wheel loader or belt conveyor;

2. The hopper discharging gates and discharging speed are controlled by computer via cylinder.After weighing, the aggregates will be conveyed to the transitional hopper above the mixer.

3. Each of the aggregate is weighed individually, the weighing accuracy is guaranteed. The accuracy of aggregate proportional ratio is realized through computer controlled system which automatically add the aggregates if there is a shortage of them, it also warns us if the aggregates are overweight.

Aggregate conveyor

1. The weighed aggregates are conveyed into the transitional hopper by belt conveyor. We can use trough belt conveyor to save place.

2. The closed aggregates belt conveyor are designed to protect the machine and enable the plant to work under all-weather condition

.

Mixing tower

1. Modern modular structure designed mixing tower. All parts of the mixing tower are connected by bolt and nuts structure. it is easy and fast to install and dismantle the whole plant.

2. It is equipped with maintenance and repair platforms and stairs.

3. Closed structure design, closed aggregate belt conveyor and external 360 degree lighting enable the all-weather operation.

Water and liquid weighing

1. Water weighing and supplying are controlled by precise weighing sensor,pneumatic butterfly valves and spherical valves, which guarantee the weighing accuracy;

2. The pressurized water by water pump can spray out and mix with the materials rapidly in the mixer, it can also wash the mixer thoroughly at the same time;

3. The liquid additive weighing system, with weighing sensor has unique leakage-proof device. the liquid additive is mixed with water and sprayed out in the mixer;

Cement and fly ash weighing and conveying

1. Cement and fly ash are stored in cement silos, conveyed to transitional hopper by screw conveyor,weighed by high-precision weighing sensor,controlled by computer.

2. The weighing hopper will discharge the cement and fly ash into the mixer by opening the pneumatic butterfly valve, when the weight reaches the set perimeter and the computer will stop the screw conveyor.

Control system

1. Automatic and manual control are available;

2. Dynamic display of the production process and monitoring in real time;

3. Saving the data of production parameters in the computer, printing of the daily, monthly and yearly statistic reports of production.

4. Weighing accuracy:automatically re-feeding if there is a shortage of aggregate and warning if the aggregates are overweight.

The first company who got CE certificate in the same industry in China.

50+patents

More than 15 years of manufacturing experience, our quality is trust worth.