- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ourscoating

-

Voltage:

-

As requested

-

Power:

-

As requeated

-

Dimension(L*W*H):

-

As requested

-

Weight (KG):

-

30

-

Color:

-

Avaliable

-

Application:

-

Metal Surface Finishing

-

Control System:

-

Electric Control Cabinet

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Product name:

-

Paint Coating System

-

Keywords:

-

Powder Production Line

-

Function:

-

High Coating Efficiency

-

Used for:

-

Powder Coated Parts

-

Usage:

-

Powder Coating Workpieces

-

Advantage:

-

High Efficiency Low Cost

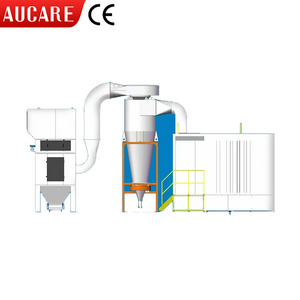

Quick Details

-

Machine Type:

-

Coating machine, Spray Booths, Painting Equipment, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Sandblasting Machine

-

Marketing Type:

-

Hot product 2019

-

Place of Origin:

-

Jiangsu,China

-

Brand Name:

-

ourscoating

-

Voltage:

-

As requested

-

Power:

-

As requeated

-

Dimension(L*W*H):

-

As requested

-

Weight (KG):

-

30

-

Color:

-

Avaliable

-

Application:

-

Metal Surface Finishing

-

Control System:

-

Electric Control Cabinet

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Product name:

-

Paint Coating System

-

Keywords:

-

Powder Production Line

-

Function:

-

High Coating Efficiency

-

Used for:

-

Powder Coated Parts

-

Usage:

-

Powder Coating Workpieces

-

Advantage:

-

High Efficiency Low Cost

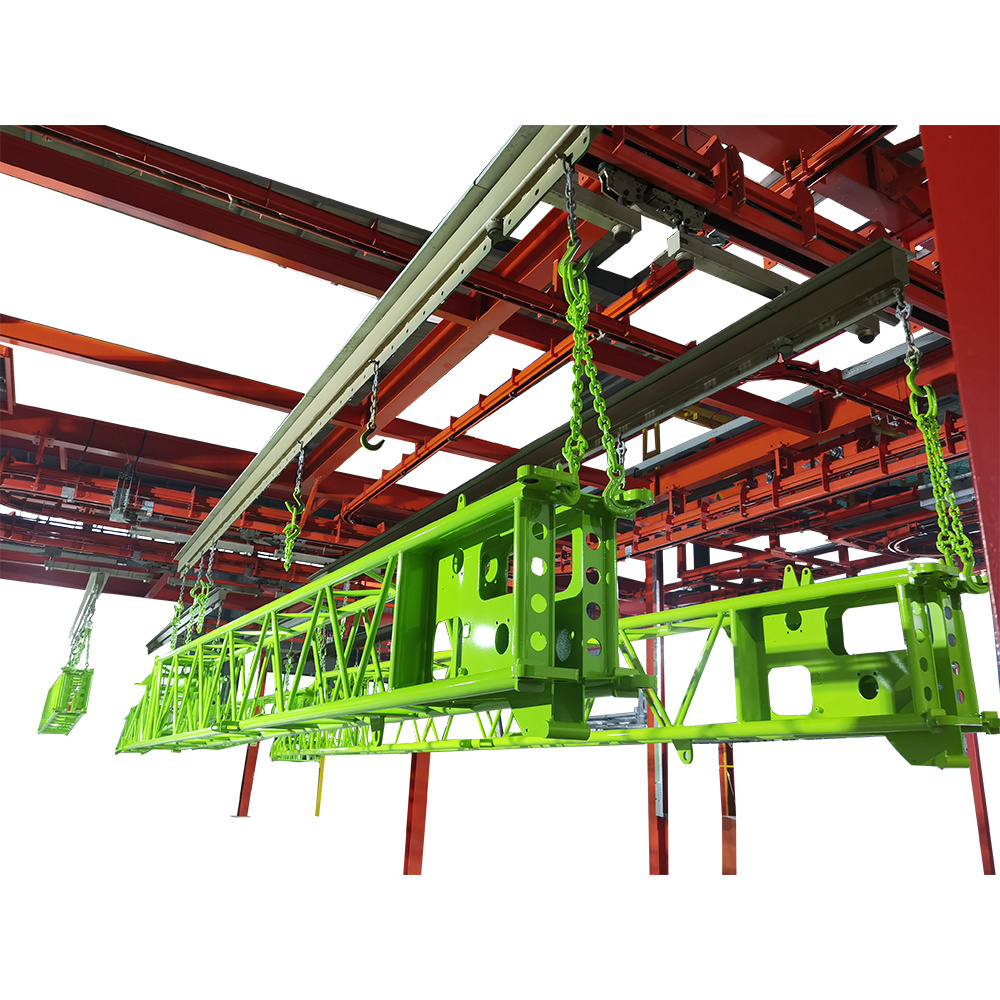

Our Projects

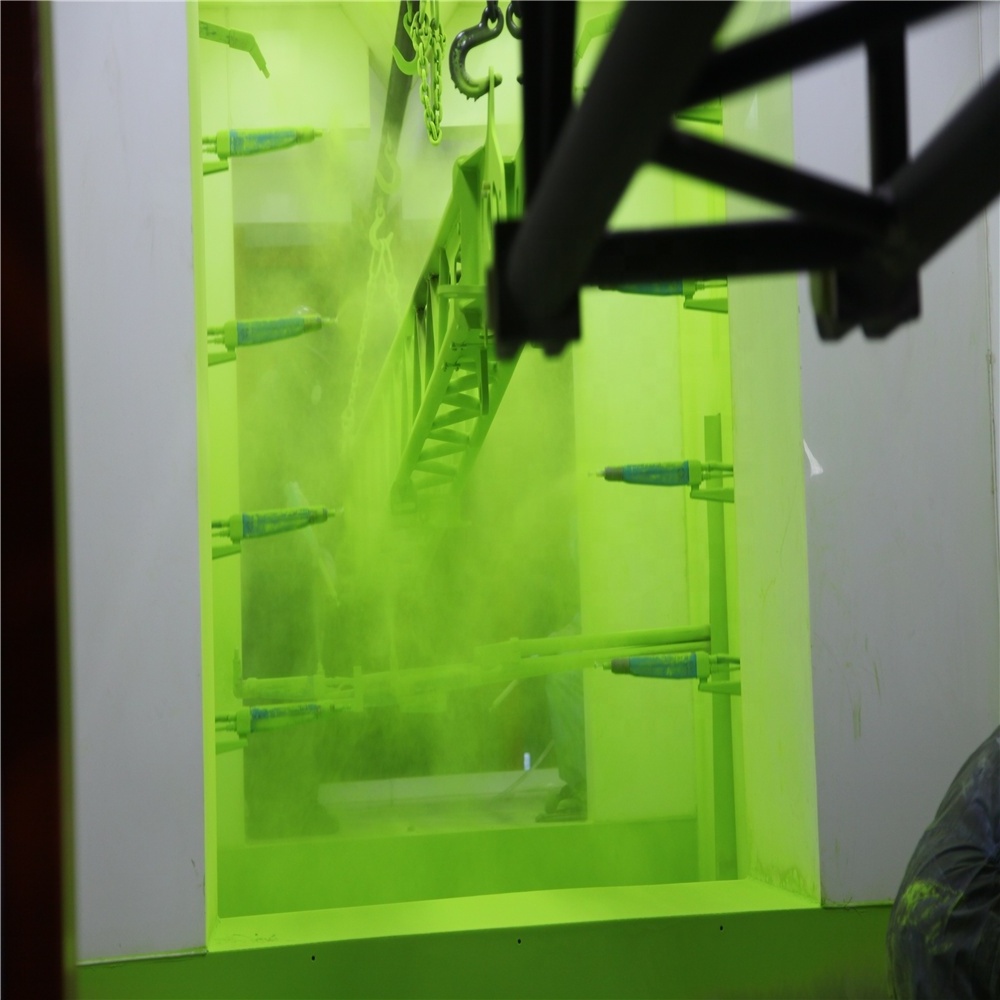

Powder Coating is an advanced method of applying a decorative and protective finish to virtually any type of metal that can be used both by industry and consumers. The powder used in the process is a mixture of finely ground particles of pigment and resin, which is electrostatically sprayed onto the surface to be coated. The charged powder particles adhere to the electrically grounded surfaces until the powder is heated and fused into a smooth coating in the curing oven. The result is a uniform, durable, high quality and attractive finish. Powder coating is the fastest growing finishing technology in North America, representing over 10% of all industrial finishing applications.

Products Description

* Coating booth

Powder coating booth with large cyclone; Powder coating booth with small cyclone; Powder coating booth with recycling system; Painting booth; Water curtain painting booth, Sand blasting booth; Shot blasting booth etc.

*

Manual powder booth

*

Automatic + manual powder booth

* Automatic powder booth

Our Customers

Certifications

Our company

|

Ours coating

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Until now we have successively provided more than 300sets of turn-key projects for automotive, construction machinery, medical equipment, home appliances, security equipment, firefighting equipment, electrical equipment, metal furniture, logistics, building materials, hardware, fitness equipment, outdoor recreation machinery and motorcycle industries.

Our Service

Pre-sales: close contact, better understanding

Freely provide pre-sale technical services including technical consultation, technical exchange, etc., and accompany domestic and foreign customers to visit OURS's existing powder coating line, painting line and ED coating line.

During sale: quality insurance, on-time delivery

The company pays attention to digesting and absorbing international and domestic advanced coating technology and process. The products are all designed and manufactured by ourselves, this not only guarantees the quality, but also reduces the equipment manufacturing cost, operation cost; so that we can deliver on time, provide better service to our customers.

After-sales: regular return visits, timely maintenance

Send skilled and experienced engineers to install the equipment and provide training services, including on-site training and professional training, theoretical training and practical training, technical training and management training. One-year warranty is available. If problem occurs, we will respond promptly: guide online or dispatch engineers for inspection.

Hot Searches