- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5%

-

Applicable Industries:

-

Factory

-

Voltage:

-

AC 220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XQ

-

Dimension(L*W*H):

-

620*700*500mm

-

Weight:

-

50 KG

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Video technical support

-

Filling range:

-

0.1-10 ml

-

Air pressure:

-

0.4-0.6 MPa

-

Power supply:

-

AC 220V

-

Speed:

-

0-35 b/m

-

Filling material:

-

Liquid

-

Bottle type:

-

Refrigeration Pipe / centrifuge tube

-

Pump:

-

Ceramic pump

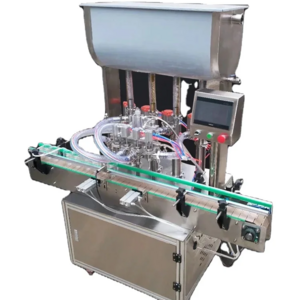

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Paper, Wood

-

Filling Material:

-

Water, Oil

-

Filling Accuracy:

-

0.5%

-

Applicable Industries:

-

Factory

-

Voltage:

-

AC 220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XQ

-

Dimension(L*W*H):

-

620*700*500mm

-

Weight:

-

50 KG

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Video technical support

-

Filling range:

-

0.1-10 ml

-

Air pressure:

-

0.4-0.6 MPa

-

Power supply:

-

AC 220V

-

Speed:

-

0-35 b/m

-

Filling material:

-

Liquid

-

Bottle type:

-

Refrigeration Pipe / centrifuge tube

-

Pump:

-

Ceramic pump

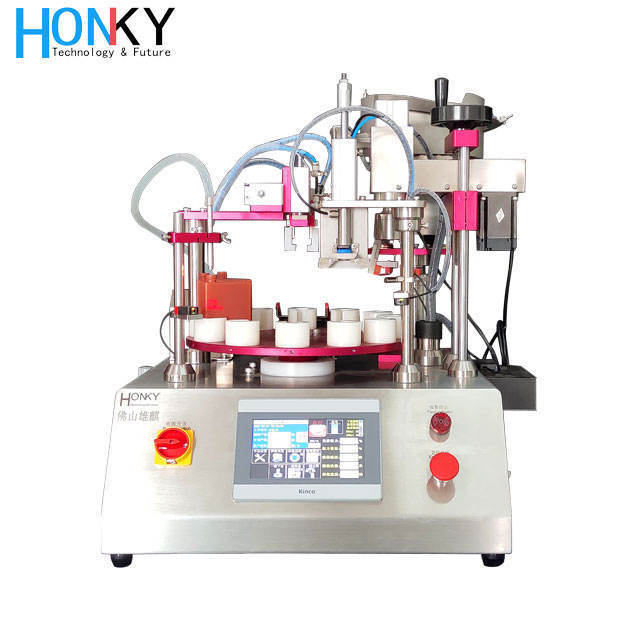

desktop automatic bio-reagent bottle filling and capping machine

XQZGX-12s uses a desktop filling and capping design, specially designed to fill and capping the Cryo tube and reagent filling. The appearance adopts desktop design, whose size is small and the material is 304 stainless steel which is easy to clean. The filling pump applies a high-precision ceramic pump to ensure filling accuracy. The filling speed is up to 2400 bottles per hour. The machine adopts the bottle mold fast loading method, different bottle types can be changed quickly and conveniently.

desktop automatic bio-reagent bottle filling and capping machine

Technical data

| Model | XQZGX-12S |

| Pump type | Ceramic pump |

| Filling accuracy | ±0.5% |

| Filling range | 0.6-6ml |

| Manufacturing speed | 25-30 PCS / minute |

| Power | AC 220V 50-60Hz 550W |

| Air pressure | 0.4-0.6Mpa |

| Machine size | 710*660*670mm (Main machine roughly) |

desktop automatic bio-reagent bottle filling and capping machine

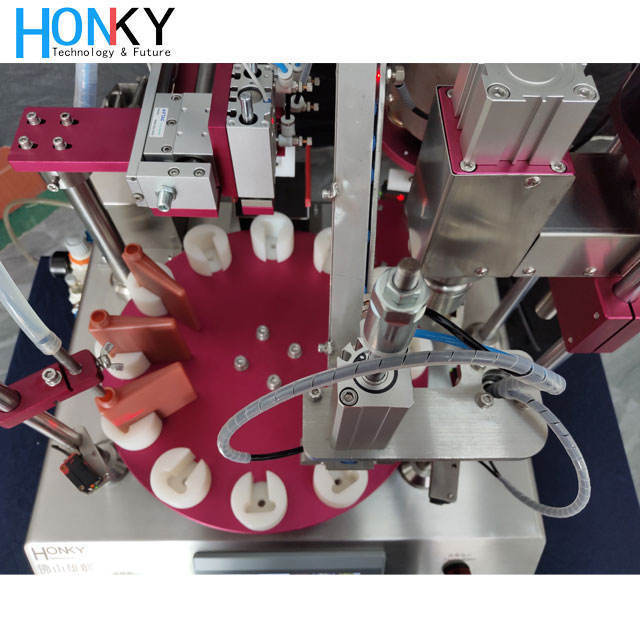

Product Display

This equipment has been tested to meet the requirements of GMP certification. A self-development system is applied to make the machine easy to operate .

the machine adopts a bottle mold fast loading method, different bottle types can be switched quickly and conveniently. Fully desktop design to make operation easy.

Packing Size

| Dimension | G.W. |

| 120*95*90 CM | 150 kg |

desktop automatic bio-reagent bottle filling and capping machine

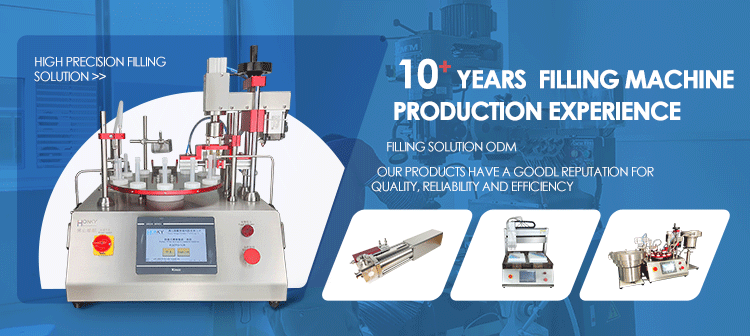

COMPANY PROFILE

Foshan Xiongqi Intelligent Technology Co.,Ltd.

is a manufacturer of precision ceramics metering pump.lt has

10 years

of industry experience in ceramic manufacturing, matching and application, and has strong technical force. Focusing on providing customers with

one-stop precision filling system

, we have

rotary electric plunger pumps series

,

pneumatic plunger pumps series

,

servo driven plunger pumps series

and so on.Aiming to improve the competitiveness of products and providing customers with the most efficient and high-quality services, our company spares no effort in product research and development.and has obtained a number of relevant national patent certificates. Foshan Xiongai lntelligent Technology Co. Ltd. stands in the world with sincerity. which is worthy of your trust.

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support. Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support installing, debugging, operation of the machine, which will indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.