- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Molding Extruding

-

Product name:

-

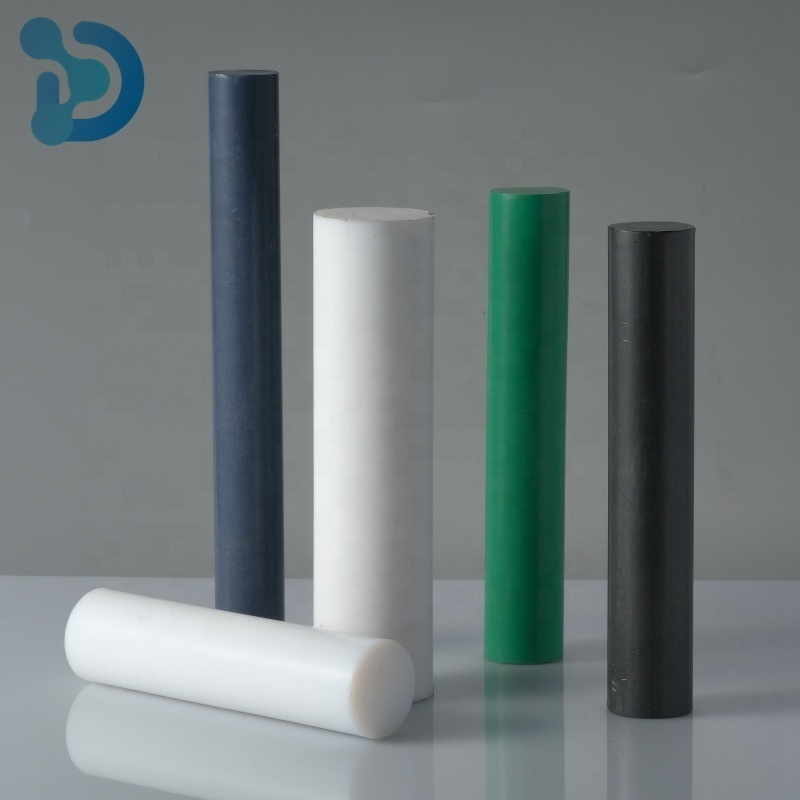

fluoroplastic rod

-

Material:

-

ptfe,pfa,pvdf,pps, peek

-

Color:

-

White; Black; Grey; Bule; Brown; Red

-

Density:

-

2.10-2.30 g/cm^3

-

Usage:

-

Industry use

-

Certificate:

-

ROHS REACH MSDS

-

Advantage:

-

self-lubricating; electric insulating; high-temperature resistant

-

Company Expreience:

-

16 years

-

Company Certificate:

-

ISO9001 ISO14001 IATF16949

Quick Details

-

Processing Service:

-

Cutting, Machining

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dechengwang

-

Model Number:

-

Molding Extruding

-

Product name:

-

fluoroplastic rod

-

Material:

-

ptfe,pfa,pvdf,pps, peek

-

Color:

-

White; Black; Grey; Bule; Brown; Red

-

Density:

-

2.10-2.30 g/cm^3

-

Usage:

-

Industry use

-

Certificate:

-

ROHS REACH MSDS

-

Advantage:

-

self-lubricating; electric insulating; high-temperature resistant

-

Company Expreience:

-

16 years

-

Company Certificate:

-

ISO9001 ISO14001 IATF16949

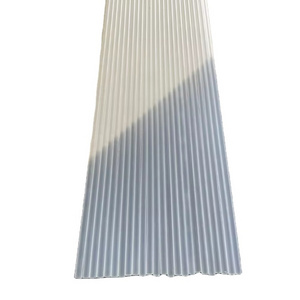

Engineering plastic CNC Machined Parts

PTFE, PTFE Compounds, PEEK, PFA, PVDF, PCTFE and compounding material enables us to generate ideal filler combinations for special requirements.

PTFE compounded with fillers like glass fibers, carbon, graphite, bronze, MoS2, PEEK etc.

* Mechanical properties improved by improving PTFE hardness while typically reducing cold flow or creep.

* Reduce liner coefficient of thermal expansion and increase thermal dimensional stability

* Increase electrical conductivity in strict percentage.

* Reduce wear rate and friction coefficient of PTFE.

* Reduce liner coefficient of thermal expansion and increase thermal dimensional stability

* Increase electrical conductivity in strict percentage.

* Reduce wear rate and friction coefficient of PTFE.

PEEK Features

* Unique physical, thermal & electrical properties

* Ideal stainless steel replacement

* Lightweight

* Biocompatibility

* High tensile strength

* High Temperature performance: continue use to +240°C (464°F), up to +260°C (500 °F)

* Low coefficient of friction and high wear resistance

* Chemically resistant.

* Ideal stainless steel replacement

* Lightweight

* Biocompatibility

* High tensile strength

* High Temperature performance: continue use to +240°C (464°F), up to +260°C (500 °F)

* Low coefficient of friction and high wear resistance

* Chemically resistant.

PCTFE Features

* Good dimensional stability and rigidity

* Low deformation under load

* Near zero moisture absorption

* Non-flammable

* Resistant to radiation

* Excellent chemical resistance

* Good corrosion resistance

Low outgassing

* Low deformation under load

* Near zero moisture absorption

* Non-flammable

* Resistant to radiation

* Excellent chemical resistance

* Good corrosion resistance

Low outgassing

PVDF Feature

* High Purity and low extractables

* Nuclear radiation resistant

* Excellent creep resistance

* Low permeability

* Great dielectric properties

* Chemically resistant to most common solvents including acids, salts, oils and steam

* Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

* Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

* Wide service temperature ranges: (-50°C (-58°F) to 150°C (302°F)

* Nuclear radiation resistant

* Excellent creep resistance

* Low permeability

* Great dielectric properties

* Chemically resistant to most common solvents including acids, salts, oils and steam

* Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

* Resistance to ultraviolet, nuclear radiation, and standard sterilization methods

* Wide service temperature ranges: (-50°C (-58°F) to 150°C (302°F)

PFA Feature

* Chemically inert to most industrial chemicals & solvents

* Good creep resistance at upper service temperature

* High melt strength, stability at high processing temperatures

* Excellent crack and stress resistance

* Low coefficient of friction and higher flex life

* Exceptionally low dielectric constant & dissipation factor

* Resists ignition and does not promote flame spread

* Wide range of temperatures: from -200°C (-328°F) to 260°C (500°F)

* In comparison to other fluoropolymers, it demonstrates greater mechanical strength, stiffness and wear resistance

* Good creep resistance at upper service temperature

* High melt strength, stability at high processing temperatures

* Excellent crack and stress resistance

* Low coefficient of friction and higher flex life

* Exceptionally low dielectric constant & dissipation factor

* Resists ignition and does not promote flame spread

* Wide range of temperatures: from -200°C (-328°F) to 260°C (500°F)

* In comparison to other fluoropolymers, it demonstrates greater mechanical strength, stiffness and wear resistance

Products - examples

FLOW CHART

OUR MATERIALS

|

Material Name

|

Main Properties

|

Compliant

|

Temperature Range

|

|

PTFE

|

This synthetic fluoropolymer of tetrafluoroethylene is known for being one of the most versatile plastics available. Being

hydrophobic, non-wetting, high density and resistant to high temperatures, it is a material with a wide variety of applications across a range of different industries. |

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-180°C to 260°C

|

|

Modified PTFE

|

Modified PTFE or TFM, is a high-density copolymerized material. It has low gas permeation and reduces cold flow. Often used in the medical field and in other applications where biocompatibility is required.

|

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-180°C to 260°C

|

|

PTFE Compounds

|

PTFE compounded with fillers like glass fibers, carbon, graphite, bronze, MoS2, PEEK etc. to improve physical, mechanical, thermal, wearing, electrical and chemical properties.

|

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-70°C to 250°C

|

|

PEEK

|

PEEK is a high-performance engineering plastic with outstanding chemical resistance, excellent mechanical strength and dimensional stabilization.

|

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-70°C to 250°C

|

|

PEEK Compounds

|

Standard PEEK virgin grade is suitable for laboratory and medical use. After being reinforced with glass fibers and carbon, its expansion rate is significantly reduced and the flexural module is increased. This makes it ideal for applications requiring increased stability, strength and rigidity at temperatures above 300°F.

|

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-70°C to 250°C

|

|

PFA

|

PFA has most of the physical and chemical properties of PTF, which is commonly used as material for piping and fittings, as well as corrosion-resistant lining of vessels.

|

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-200°C to 260°C

|

|

PVDF

|

PVDF is a special material in fluoropolymer. Maximum purity, strength, and resistance to solvents, acids, bases and heat, all those characteristics make PVDF popular in some critical applications.

|

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-50°C to 150°C

|

|

PCTFE

|

PCTFE (polychlorotrifluoroethylene) is a fluoropolymer material with exceptional strength, rigidity and stability in dimensions.

|

FOOD CONTACT AVAILABLE, RoHS, REACH

|

-400°C to 150°C

|

DCW PRODUCTION EQUIPMENT

INSPECTION STANDARD

TOP 5 Advantage of DCW

PACKAGE

Hot Searches