- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2000 KG

-

Product name:

-

Ball Mill Machine

-

After-sales Service Provided:

-

Engineers

-

Keywords:

-

Raymond Vertical Roller Mill

-

Color:

-

Customer Requirement

-

After sale service:

-

Engineers On-site Service

-

Quality:

-

ISO9001:2008 Certificate

-

Output size:

-

150-2500mesh

-

Model:

-

1200B

-

Usage:

-

Crushing Work

-

Price:

-

Platform

Quick Details

-

Capacity(t/h):

-

50 Set/Sets per Month

-

Place of Origin:

-

HENAN

-

Brand Name:

-

ROCKWEEL

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2000 KG

-

Product name:

-

Ball Mill Machine

-

After-sales Service Provided:

-

Engineers

-

Keywords:

-

Raymond Vertical Roller Mill

-

Color:

-

Customer Requirement

-

After sale service:

-

Engineers On-site Service

-

Quality:

-

ISO9001:2008 Certificate

-

Output size:

-

150-2500mesh

-

Model:

-

1200B

-

Usage:

-

Crushing Work

-

Price:

-

Platform

Product Description

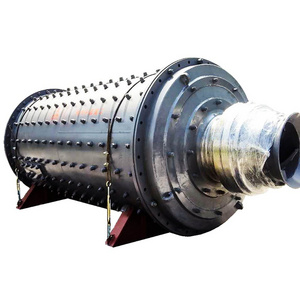

industry. Ball Mills can grind various ores and other materials either wet or dry, depending on requirements.

Baichy Ball Mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such as

cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

Dry type ball grinding mill is to grind feldspar, glass, dolomite, quartz, silica sand etc. Using ceramic lining plate, the raw

material could keep high purity. It also could be get very fine powder such as 1500 mesh together with air classifier machine.

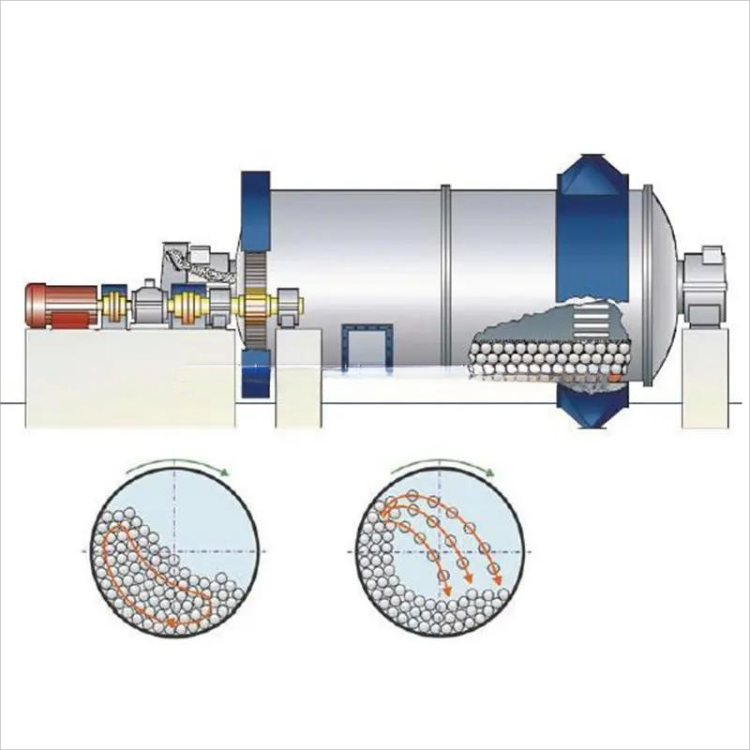

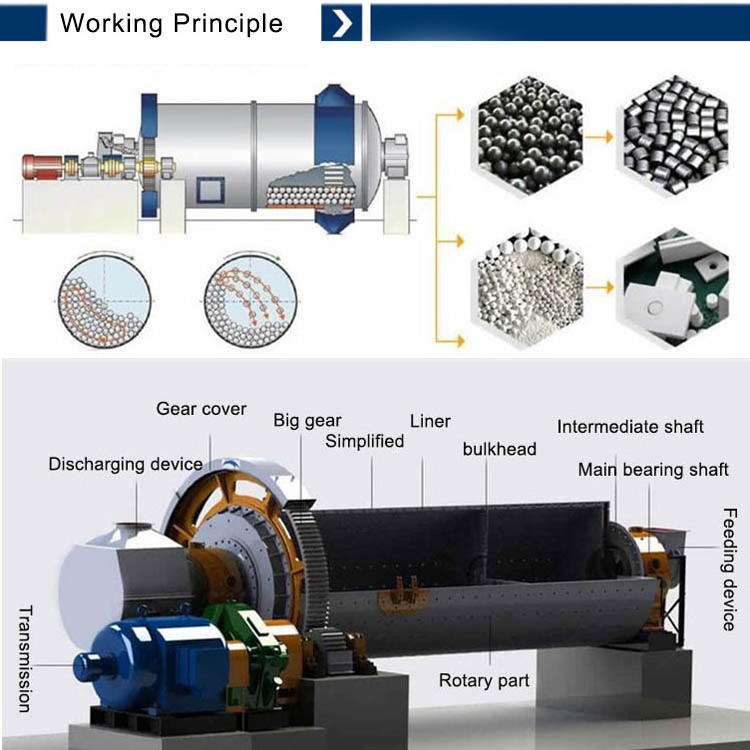

Working principle

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes

evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in

different specifications.Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it

will give a heavy blow to materials, playing a role of grinding. Materials after crushed in the first bin shall enter bin across

single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding. The

ground materials are discharged through the discharging board thus the grinding process is finished.

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes

evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in

different specifications.Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it

will give a heavy blow to materials, playing a role of grinding. Materials after crushed in the first bin shall enter bin across

single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding. The

ground materials are discharged through the discharging board thus the grinding process is finished.

Specification

|

Model NO.

|

6S

|

Tbele Size

|

4520*1850*156mm

|

|

|

|

Stroke

|

8-36mm

|

Motor Power

|

1.1kw

|

|

|

|

Time/min

|

240-380

|

Dimension

|

5630*1850*900mm

|

|

|

|

Landscape

|

0-5°

|

Table Weight

|

650kg

|

|

|

|

Material

|

Feeding Size

|

Mine Density

|

Flushing Water

|

Capacity(t/h)

|

|

|

Coarse Sand

|

2-0.5mm

|

10-30%

|

0.5-3.5t/h

|

1-2.5

|

|

|

Fine Sand

|

0.5-0.074mm

|

|

|

0.8-1.2

|

|

|

Ore Mud

|

0.0774-0.037mm

|

|

|

0.3-0.6

|

|

Packing & Delivery

Can be packed according to user requirements, wooden box, tin

Hot Searches