- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depending on capacity

-

Weight:

-

20-50ton

-

Product name:

-

Single Drum Coal Biomass Wood Pellet Fuel Fired Steam Boiler

-

Rated steam capacity:

-

4-35 ton/h

-

Rated steam pressure:

-

1.25/1.6/2.5 Mpa

-

Rated steam temperature:

-

194/204/225 Degree

-

Thermal efficiency:

-

84 - 85%

-

Effective area of grate:

-

3.22-30 M2

-

Fuel consumption:

-

300-1100 kg/h

-

Exhaust flue gas temperature:

-

135-145 C

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Overseas service center available

Quick Details

-

Steam Production:

-

Max. 35t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinli

-

Dimension(L*W*H):

-

Depending on capacity

-

Weight:

-

20-50ton

-

Product name:

-

Single Drum Coal Biomass Wood Pellet Fuel Fired Steam Boiler

-

Rated steam capacity:

-

4-35 ton/h

-

Rated steam pressure:

-

1.25/1.6/2.5 Mpa

-

Rated steam temperature:

-

194/204/225 Degree

-

Thermal efficiency:

-

84 - 85%

-

Effective area of grate:

-

3.22-30 M2

-

Fuel consumption:

-

300-1100 kg/h

-

Exhaust flue gas temperature:

-

135-145 C

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Overseas service center available

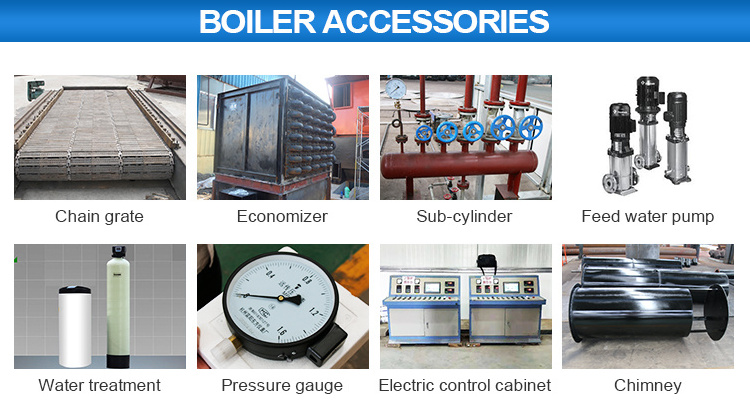

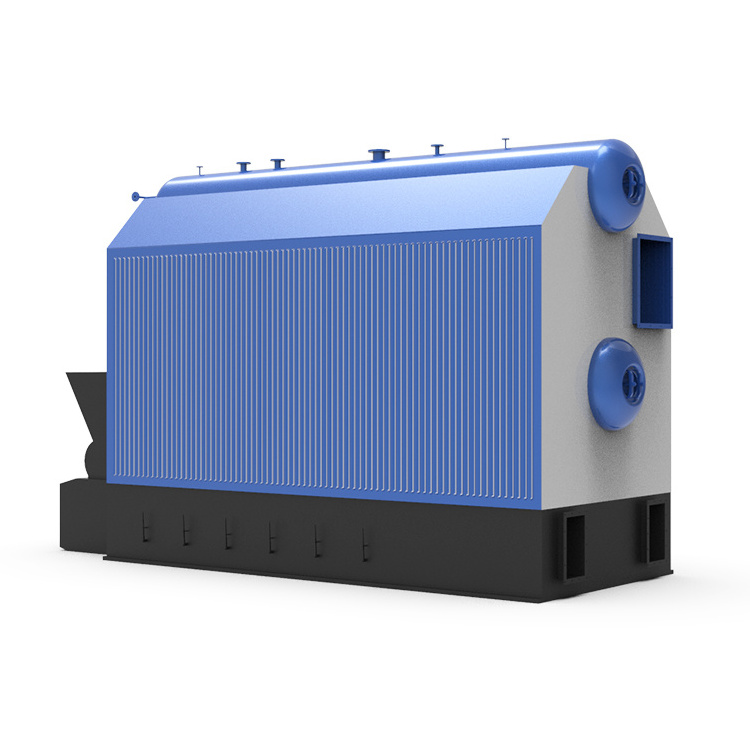

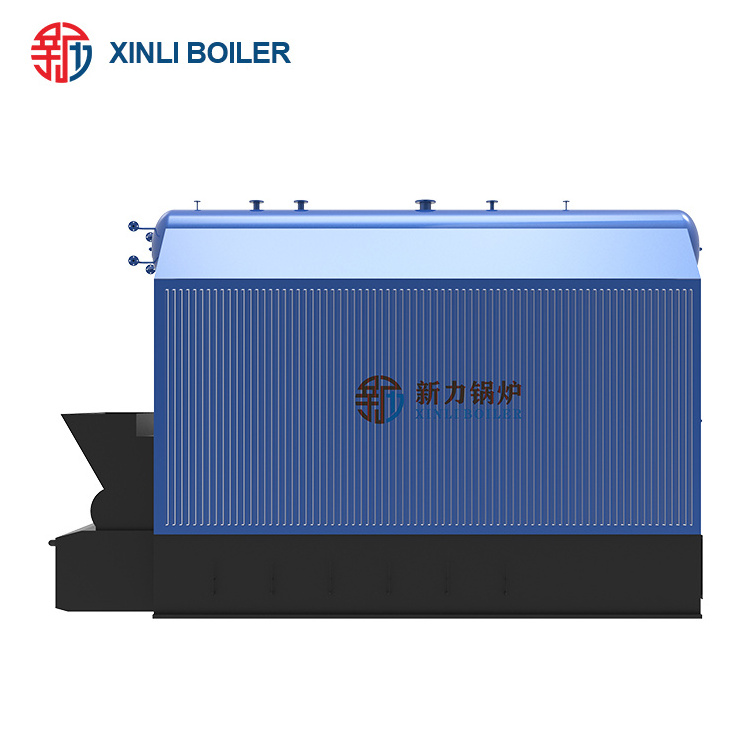

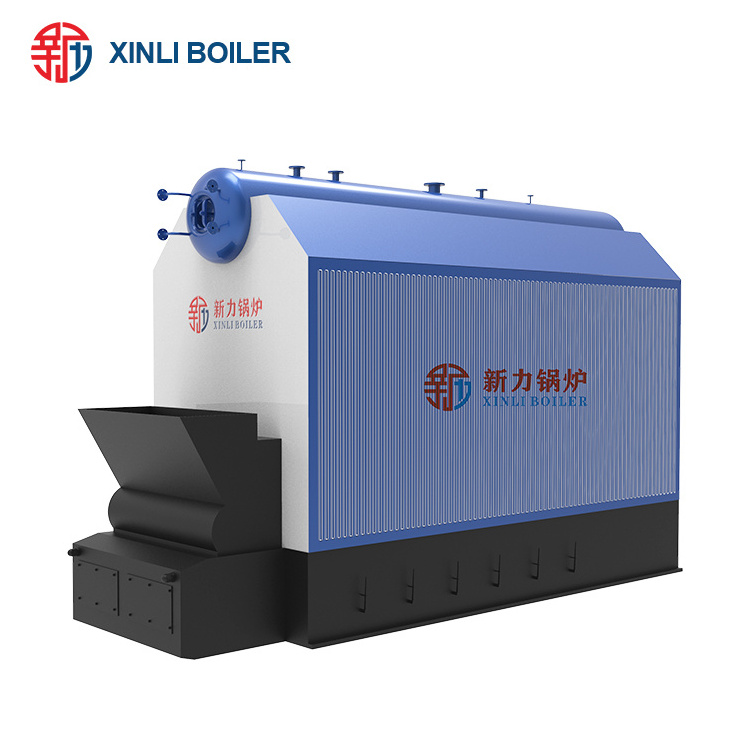

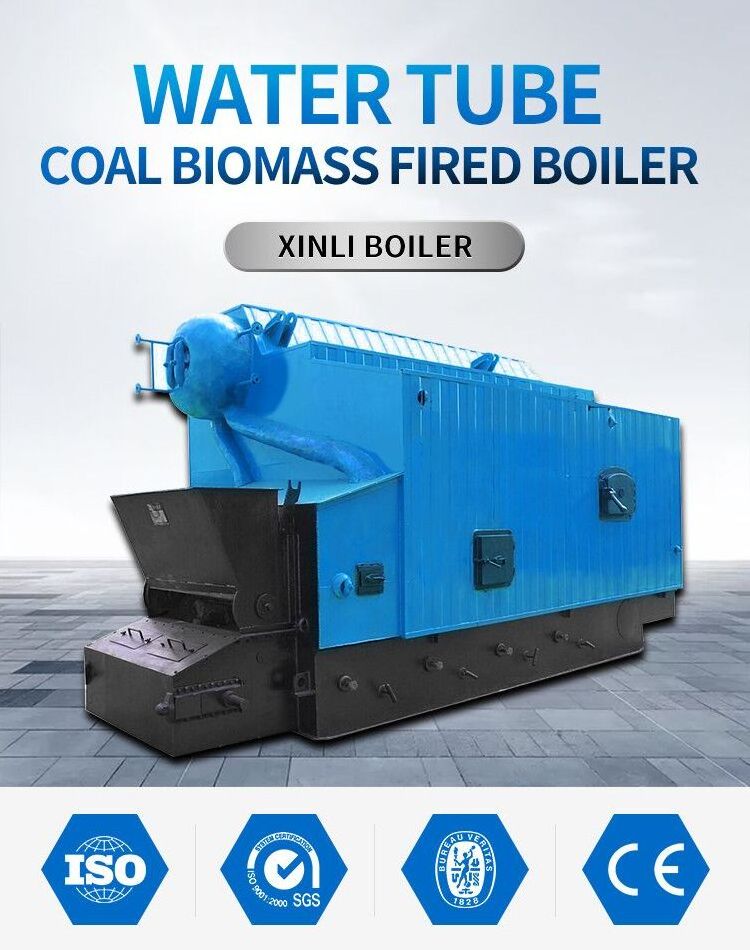

Horizontal Chain Grate Three Pass Single Drum Coal Biomass Wood Pellet Fuel Fired Steam Boiler

Model:SZL Series Coal / Biomass Boiler

Structure:Water Tube Double Drum

Fuel:Coal, Biomass, Wood, Chip, Husk, Sawdust, Jute, Shell, Waste Solid Fuel etc.

Capacity: 4 - 35 ton

Pressure:1.25/1.6/2.5 Mpa (12.5Bar/16Bar25Bar)

Temperature:194/204/225 C

Application:Rice Mill,Chemical,Paper Mill,Sugar Mill,Textile Mill,Rubber Plant etc

The SZL double drum water tube steam boiler is horizontal type water tube boiler, the combustion equipment is chain grate. The boiler adopts fast assembly or packaged assembly structure, boiler with steam capacity lower than 4t/h is fast assembly water tube structure, boiler with steam capacity between 4~35t/h is consisted of upper part (boiler heated part) and lower part(combustion equipment). The wood fired steam boiler has the advantages of compact structure, high steam quality, sufficient output, operate convenient and environmental protection.

| Structure | Advantage |

| Assembly of boiler body and combustion equipment separately | Easy installation on site |

| With long and short drum drum structure | Increased a large number of convective heating surfaces |

| Use front and rear arch structure to promote heat transfer | Enhance the adaptability of coal |

| Double-sided independent air intake structure | Guaranteed combustion effect |

| Conservative grate area, Long burning time of coal | Improve boiler thermal efficiency |

| Light insulation insulation material, and steel plate molding | Simple and elegant appearance |

| The boiler room is a single floor | Short construction period and low cost |

| Model | SZL4 | SZL8 | SZL10 | SZL15 | SZL20 | SZL25 |

| Rated Steam Capacity (t/h) | 4 | 8 | 10 | 15 | 20 | 25 |

| Rated Working Pressure(Mpa) | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 | 1.25/1.6/2.5 |

| Feed Water Temperature (℃) | 20 | 20 | 60 | 105 | 105 | 105 |

| Steam Temperature (℃) | 194/204/226 | 194/204/226 | 194/204/226 | 194/204/226 | 194/204/226 | 194/204/226 |

| Body Heating Area (m) | 96.5 | 177 | 228 | 311 | 727 | 920 |

| Grate Area(m) | 5.5 | 10.4 | 11.8 | 17.7 | 20.8 | 25.8 |

| Fuel Type | Second-class Bituminous Coal, Meagre Coal, Biomass etc | |||||

| Combusion Method | Chain Grate | |||||

| Overall Dimension (m) | 7.6×2.9×3.5 | 7.1×3.3×3.5 | 7.8×3.2×3.5 | 9.5×3.3×3.5 | 11.6×3.2×3.5 | 11.7×3.6×3.5 |

| Weight of Biggest Part (t) | 36.6 | 33 | 35 | 40 | 45 | 50 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||