- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8000*2400*3800

-

Power (kW):

-

25 kW

-

Weight (KG):

-

121000 KG

-

Name:

-

hot splicing press for conveyor belt

-

Machine Type:

-

floor tile vulcanizing tools

-

Application:

-

making rubber tile

-

easy operation:

-

high effencicy,high technology,high production

-

Plunger stroke:

-

250mm

-

using life:

-

more than 15 years

-

Product name:

-

Rubber floor tile making machine

-

keyword:

-

rubber tile vulcanizing machine

-

Weight:

-

3600kg

-

Advantage:

-

High Producing Efficiency

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

guangyue

-

Voltage:

-

380v/220v

-

Dimension(L*W*H):

-

8000*2400*3800

-

Power (kW):

-

25 kW

-

Weight (KG):

-

121000 KG

-

Name:

-

hot splicing press for conveyor belt

-

Machine Type:

-

floor tile vulcanizing tools

-

Application:

-

making rubber tile

-

easy operation:

-

high effencicy,high technology,high production

-

Plunger stroke:

-

250mm

-

using life:

-

more than 15 years

-

Product name:

-

Rubber floor tile making machine

-

keyword:

-

rubber tile vulcanizing machine

-

Weight:

-

3600kg

-

Advantage:

-

High Producing Efficiency

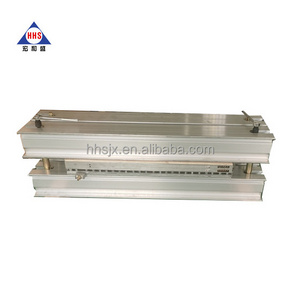

conveyor belt vulcanizing press

1. CE, ISO, S.G.S, excellent seal and long life.

2. High production efficiency, low mold-locking speed, protect mold.

3. Less energy consumption, low noise, without oil spilling or off pressure.

4. Reliable structure, easy to be operated.

1. Main use

The Muliti-Unit Press works for the vulcanization of the fabric coin conventional conveyor belt,nylon conveyor belt,PVG conveyor belt,anti-flammability conveyor belt,wirerope conveyor belt ,and conveyor belt of textile construction etc.PLC is used in the control system of mainframe that can meet multi-progtam automafic control,and platen temperature can be measured and adjusted automatically during the course of curing.

2. Advantages

1. PLC control, high level automatic.

2. New heating insulation material, withstand pressure, high heat resistance .

3. Equipped with hydraulic auto guard device so ensure of the quality of belt edges, and improve the working efficiency.

4. The vulcanizing press can distribute the pressure averagely.

5. Equipped with a unique heat balance system; it can control the deformation and improve the belt quality.

3. Technical parameter

|

Parameters/version |

XLB1200*1200*2 |

XLB-Q1200*2700*1 |

XLB-Q1400*8000*2 |

XLB-Q1400*2500*1 |

XLB-Q2000*2500*1 |

|

Mould closing force(MN) |

3.15 |

850 |

3400 |

1200 |

1800 |

|

Plunger stroke (mm) |

400 |

250 |

400 |

500 |

250 |

|

Platen unit area pressure (Mpa) |

2.18 |

2.6 |

3.1 |

2.4 |

2.88 |

|

Hot plate layer |

2 |

1 |

2 |

1 |

1 |

|

Main motor power (kw) |

7.5 |

5.5 |

37.5 |

19 |

22 |

|

Daylight (mm) |

200 |

250 |

200 |

500 |

250 |

|

Size (length*width*height) (mm) |

2600*1340*2400 |

2700*1860*2600 |

8000*2400*3800 |

2500*3100*3600 |

3520*2900*3550 |

|

Weight (kg) |

9500 |

20000 |

121000 |

22000 |

55000 |

|

Hot platen size (mm) |

1200*1200 |

1200*2700 |

1400*80000 |

1400*2500 |

2000*2500 |

rubber floor vulcanizing tools with CE S.G.S ISO certificates

1.feature:

1. we usually design as clients' products and details request. our machine is 4 working layers, 1 hour can made 8 pcs rubber floor. We can also according your needs. and decide the working layers.

2.the machine is matched with manual push-out device .

3. we also can provide the different size of the molds, from 20mm to 75mm thickness.

4. rubber mixer can also provided, if needed.

5. The press with 12 pcs molds and rubber mixer is only 8m3 of the flooring area, it can be LCL for loading, So the sea freight is very cheap.

6. We also can according to the customers' requirement, and design the non-standard type of rubber tile vulcanizing machine.

2. Advantage:

1. CE, ISO, SG.S, excellent seal and long life.

2. High production efficiency, low mold-locking speed, protect mold.

3. Less energy consumption, low noise, without oil spilling or off pressure.

4. Reliable structure, easy to be operated.

3 parameters of rubber vulcanizing press:

|

Item |

XLB-D550*550*4 vulcanizing machine |

|

|

Total pressure |

MN |

0.50 (50 tons) |

|

Hot plate size |

MM |

550*550*60 |

|

Plate clearance |

MM |

150 |

|

Working layer |

layer |

4 |

|

Hot plate quantity |

Piece |

5 |

|

Piston stroke |

MM |

400 |

|

Piston quantity |

Set |

1 |

|

Piston diameter |

MM |

200 |

|

Structure mode |

|

Four columns |

|

Operation system |

|

Manual operation |

|

Working pressure |

Mpa |

1.65 (16.5kg/cm 2 ) |

|

Motor power |

KW |

2.2 |

make rubber tile mould:

product purpose:

4 products and workshop:

5 After-sales Service:

1 over seas service, two technician provides debug and training FOR 7-14 DAYS, charge 60 USD per day for one man .and you are responsible for round tickets, visa. Living, eating and so on.,one technician train worker how to produce rubber powder; another one rain worker how to make rubber tile.

2 during warranty, if quality problem appears ( not include man made problem ) , we can replace it by free..

3 we will reply during 24 hours once problem appears, we can solve through guide picture or video; if problem can not solved through these solutions , we can send engineer to your factory.

------about our manufactory

Qingdao Guangyue Rubber Machinery Co.,Ltd established in 1971,we are specinizing in producing rubber machines,like rubber vulcanizing press,open mixing mill,rubber kneader,rubber extruder,rubber calender etc,we had a great feed back from south America,north Europe,Middle East,Aisa and so on,welcome to visit our manufacturer !

6 Certificates: