- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

All models

-

Voltage:

-

no

-

Dimension(L*W*H):

-

as required

-

Weight:

-

by models

-

Features:

-

by drawing

-

Certification:

-

API

Quick Details

-

Application:

-

to filt liquid and slurry from mud and oil

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lake Petro

-

Model Number:

-

All models

-

Voltage:

-

no

-

Dimension(L*W*H):

-

as required

-

Weight:

-

by models

-

Features:

-

by drawing

-

Certification:

-

API

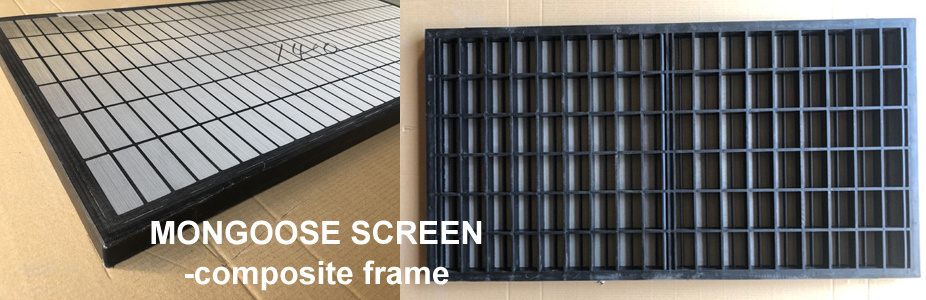

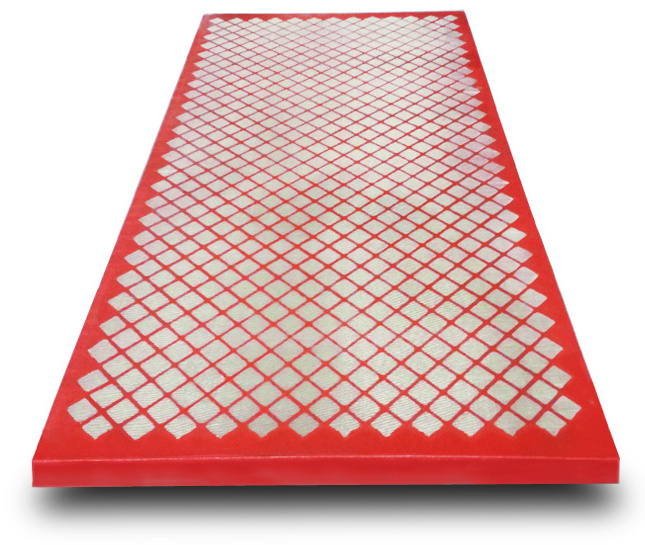

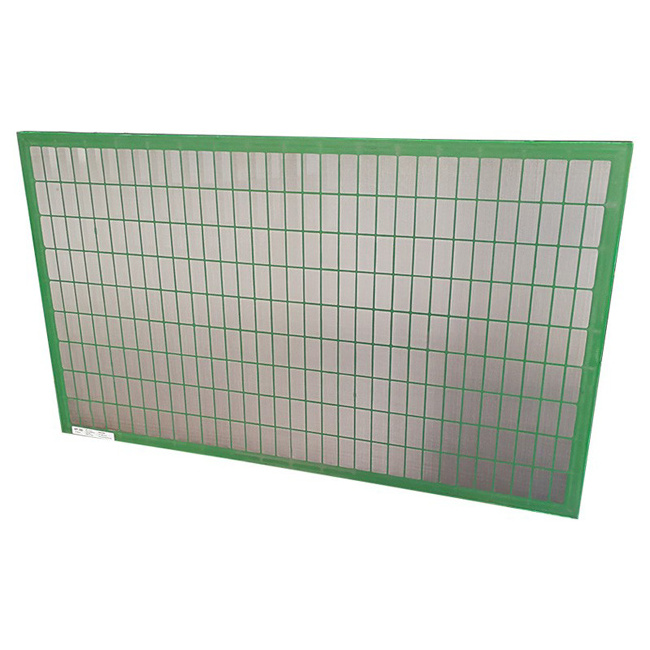

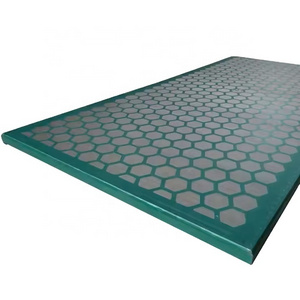

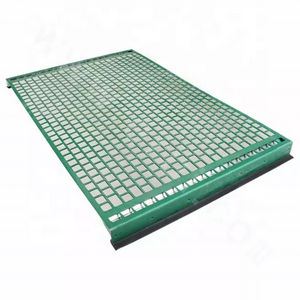

Composite Frame Screen mesh range 40-325 for Shale Shaker

1. Composite frame screen is mainly made up of composite frame and 2 or 3 layers stainless steel wire cloths. The wire cloth can be combined with the frame with metal rubber lining, or directly bonded on the frame .

2. Every layer wire cloth has different meshes, accurately and reasonably make screening more micromesh .

3. High-strength composite frame screen and moderate tensional screening cloth greatly enhances the tolerable flow .

4. Rapid wedge tensioning device makes screen installation more convenient, and saves time of machine halt for changing .

5. Wire cloth is divided into several independent small cloths to prevent excessive expansion of local damage .

6. Excellent high-strenght composite frames enhance corrosion resistance, have good shock absorption and extend working life of screen .

| Model | Model for Shaker | Mesh Range | Dimension | Weight |

| LPC-1 | SWACO MONGOOSE | 40-325 | 1165 * 585 * 40 mm | 12 kg |

| LPC-2 | BRANDT KING COBRA SHAKER | 40-325 | 1250 * 635 * 28 mm | 10 kg |

| LPC-3 | BRANDT VSM300 | 40-325 | 890 * 388 * 39 mm | 9.5 kg |

| LPC-4 | FLUID SYSTEM SHKER | 40-325 | 1072 * 733 * 29 mm | 11.3 kg |