- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

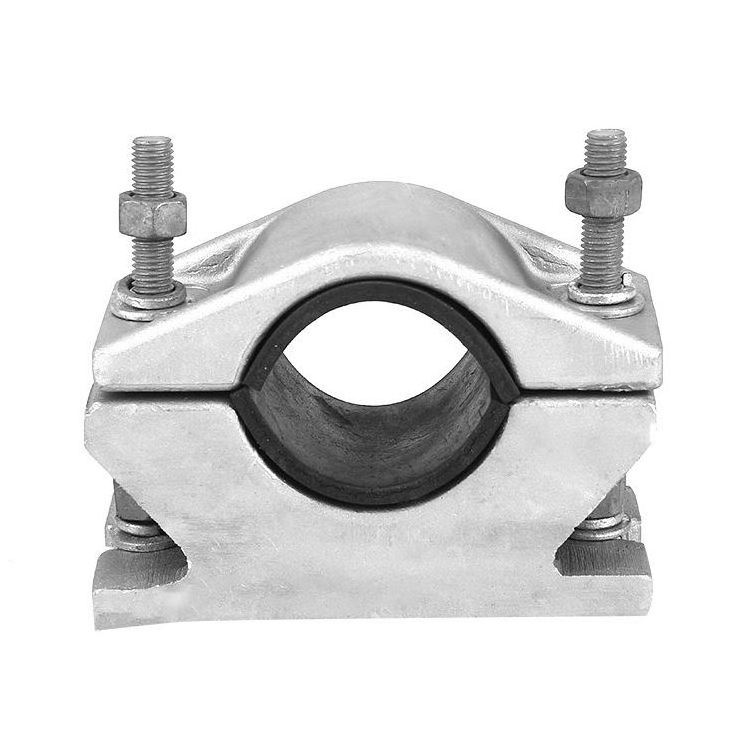

CABLE CLEATS

-

Frame:

-

54mm*2.0mm,marine grade,Non-magnetic 316L

-

Closure Hardware:

-

316SS M8 or M10 bolt and Nylon Lock Nut

-

Integral Pad:

-

Smoke,Low Fume ,Halogen Free

-

Tools Required:

-

Wrench

-

Mounting Bolt:

-

Provided with the Cable Cleat

-

Max and Min Temperature:

-

-40℃--120℃

-

Needle Flame Test:

-

30S

-

Resistance to Impact:

-

Very Heavy

-

color:

-

silver

Quick Details

-

Brand Name:

-

dpair

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

JGW

-

Product name:

-

CABLE CLEATS

-

Frame:

-

54mm*2.0mm,marine grade,Non-magnetic 316L

-

Closure Hardware:

-

316SS M8 or M10 bolt and Nylon Lock Nut

-

Integral Pad:

-

Smoke,Low Fume ,Halogen Free

-

Tools Required:

-

Wrench

-

Mounting Bolt:

-

Provided with the Cable Cleat

-

Max and Min Temperature:

-

-40℃--120℃

-

Needle Flame Test:

-

30S

-

Resistance to Impact:

-

Very Heavy

-

color:

-

silver

Products Description

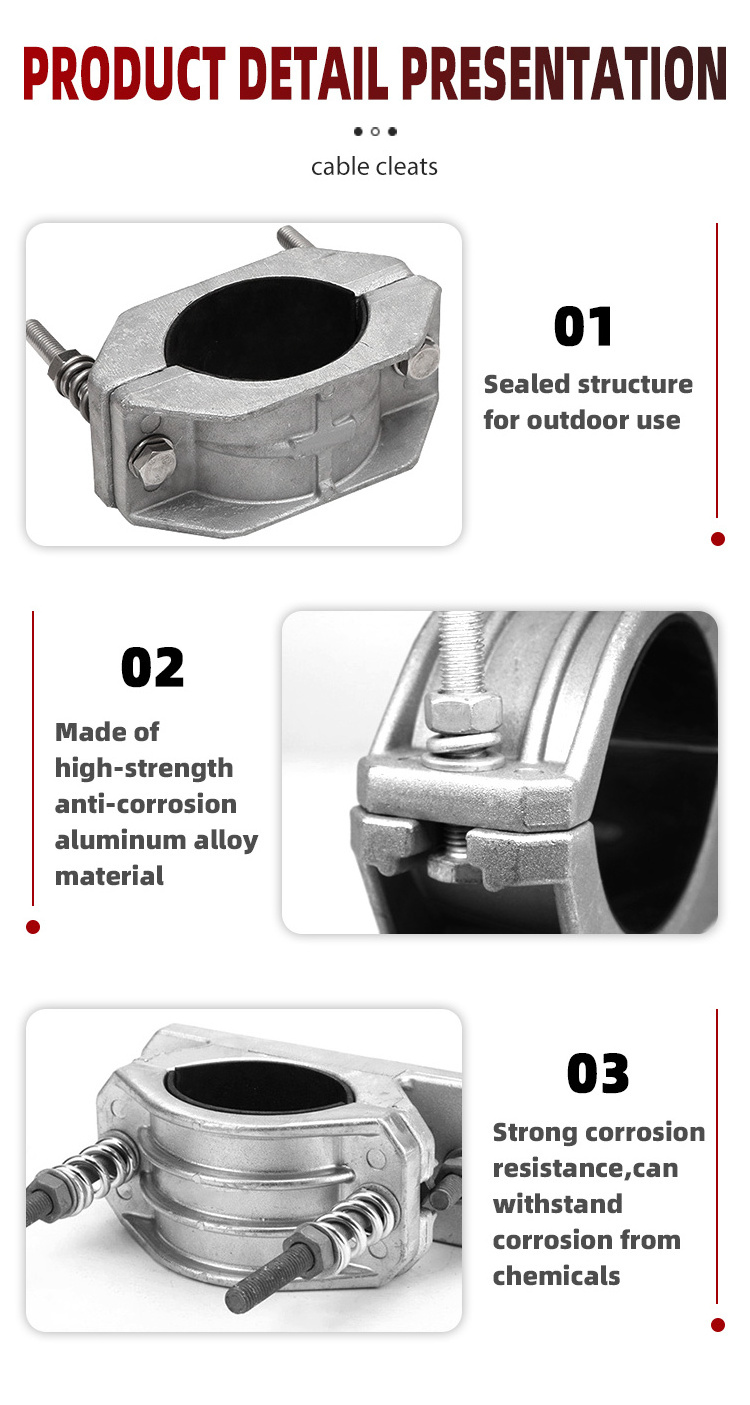

cable cleats

Cable cleats provide effective cable management of low, medium and high voltage power cables requiring short circuit protection.

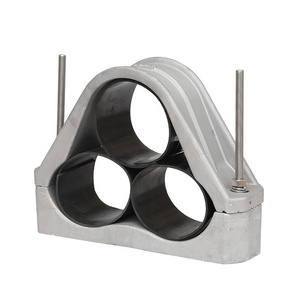

cable cleats used to clamp and retain low, medium and high voltage cables in the event of a short circuit, including 11kV/33kV MV-HV power cables – trefoil cable configurations can be cleated using our best quality manufactured cable cleats in a choice of materials including nylon, stainless steel and aluminium.

stock for high-performance cable applications including fire resistant, low smoke zero halogen, flame retardant. Epoxy coated version available for harsh environments and outdoor. We also supply Trefoil Cable Cleat for medium/high voltage power cable cleating applications such as Triplex cables.

Liners come as standard which help to restrain the cable(s) within vertical applications. Where thermal elongation of cables occurs, the liner also provides a layer of protection between the cable sheath and the cable cleat during normal operation. This additional layer protects the cable from chafing on any mounting surface due to differential movements such as those found in marine and offshore applications.

The liners also assist in the extra protection of cable(s) in the event of short circuit fault conditions.

Our cable cleats are Suitable for use with cable diameters 15 to 150 mm for a wide range of Plain finish for normal industrial areas or indoor application.

Features:

Ideal for installations where the cables are subject to top short circuits.

The width of the clamping-area provides a controlled pressure on the cable and avoids damage to the isolation.

Suitable for indoor and outdoor use.

No alteration of strength and signs of degrading within temperatures ranges from -80°C to +120 °C. (shortly +220°).

Application :

Fastening single conductor, low,midand high voltage cables and pipes.

|

Type

|

Applicable outside diameter of cable Φ(mm)

|

L1

|

L2

|

L3

|

L4

|

M

|

|

JGW-1

|

75-84

|

120

|

150

|

90

|

114

|

2-M12

|

|

JGW-2

|

85-94

|

130

|

160

|

80

|

124

|

2-M14

|

|

JGW-3

|

95-104

|

140

|

175

|

80

|

138

|

2-M14

|

|

JGW-4

|

105-114

|

150

|

185

|

80

|

150

|

2-M14

|

|

JGW-5

|

115-124

|

160

|

195

|

90

|

160

|

2-M14

|

|

JGW-6

|

125-134

|

175

|

215

|

90

|

175

|

2-M16

|

|

JGW-7

|

135-146

|

190

|

230

|

100

|

195

|

2-M16

|

|

JGW-8

|

140-165

|

210

|

265

|

100

|

205

|

2-M16

|

BAZHOU DPAIR HARDWARE EQUIPMENT CO., LTD. is a specialized manufacturer of hydraulic crimping tools,Our company has won ISO9001, CE certificate and other local certificates,as well as "National High-tech Enterprise" and "Excellent and Innovative Enterprise

Bazhou Depaier Hardware Machinery Co., Ltd. was established in 2010. The company is a high-tech enterprise in Hebei Province. It is located in Bazhou City, Hebei Province, 90 kilometers away from Beijing. It covers an area of 18,000 square meters and has more than 210 employees. The company integrates R&D, production and sales of electric power engineering machinery and has an engineering machinery R&D laboratory. The company has been engaged in overseas sales since its establishment. Now its products are sold to more than 90 countries and have agents in Australia, Russia, Dubai, Saudi Arabia, India and other places. After years of continuous efforts, the power engineering machinery produced by our company has now reached the leading domestic level, contributing to accelerating the country's mechanization construction. We have advanced production technology and production equipment and can develop or customize products for customers according to their needs. Sincerely look forward to every customer or friend coming to our company to visit or negotiate business! I look forward to cooperating with you and extend my best wishes to you.

Product packaging

FAQ

1. Is it in stock? and how many days get it ?

Yes, can send out immediately if we have stock,

if not,will 7-15 days.

2. What is your MOQ ?

One set is MOQ,

Larger MOQ,and better price.

3. What the delivery time ?

All depend on the order quantity,usually bulk

For sample orders, we deliver within 7-15 days

For 3-15 sets, we will deliver in 10-25 days.

For orders of more than 15 units, we deliver in 15-40 days

By ocean 30-45days

4. What payment way you accept ?

Alipay, Paypal, TT,Western Union,MoneyGram

Post-sales service

First of all, the probability of failure of our equipment is very low. According to the customer's feedback,

there will be no failure within 2 years under normal working conditions. Our company has professional translators, can communicate

with customers in multiple languages, in order to facilitate the installation and commissioning of products. When the equipment is

delivered, we will give enough worn parts to meet the future maintenance work and daily maintenance work If the equipment is

damaged within 2 years and needs to be repaired, we will send the required accessories by express delivery, which is free of

charge. If our engineers determine that the after-sales service must be on-site, our maintenance engineers will carry out on-site

maintenance services within 72 hours.

there will be no failure within 2 years under normal working conditions. Our company has professional translators, can communicate

with customers in multiple languages, in order to facilitate the installation and commissioning of products. When the equipment is

delivered, we will give enough worn parts to meet the future maintenance work and daily maintenance work If the equipment is

damaged within 2 years and needs to be repaired, we will send the required accessories by express delivery, which is free of

charge. If our engineers determine that the after-sales service must be on-site, our maintenance engineers will carry out on-site

maintenance services within 72 hours.

Hot Searches