- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYALPACKING

-

Dimension(L*W*H):

-

4.7*4.5*2m

-

Weight:

-

1500 kg

-

Marketing Type:

-

New Product 2022

-

Max machine speed:

-

80 ~ 150 pieces/min

-

Max feeding size (L * W):

-

2200*880mm

-

Min feeding size (L * W):

-

600*230mm

-

Negative knife (A * B):

-

175mmX60mm

-

Positive knife (A * B):

-

90mm*90mm

-

Min height of box (H):

-

115mm

-

Machine size:

-

4.7*4.5*2m

Quick Details

-

Type:

-

Slotting and Stacker Machine

-

Production Capacity:

-

80 ~ 150 pieces/min

-

Max. workable width:

-

2200*880mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYALPACKING

-

Dimension(L*W*H):

-

4.7*4.5*2m

-

Weight:

-

1500 kg

-

Marketing Type:

-

New Product 2022

-

Max machine speed:

-

80 ~ 150 pieces/min

-

Max feeding size (L * W):

-

2200*880mm

-

Min feeding size (L * W):

-

600*230mm

-

Negative knife (A * B):

-

175mmX60mm

-

Positive knife (A * B):

-

90mm*90mm

-

Min height of box (H):

-

115mm

-

Machine size:

-

4.7*4.5*2m

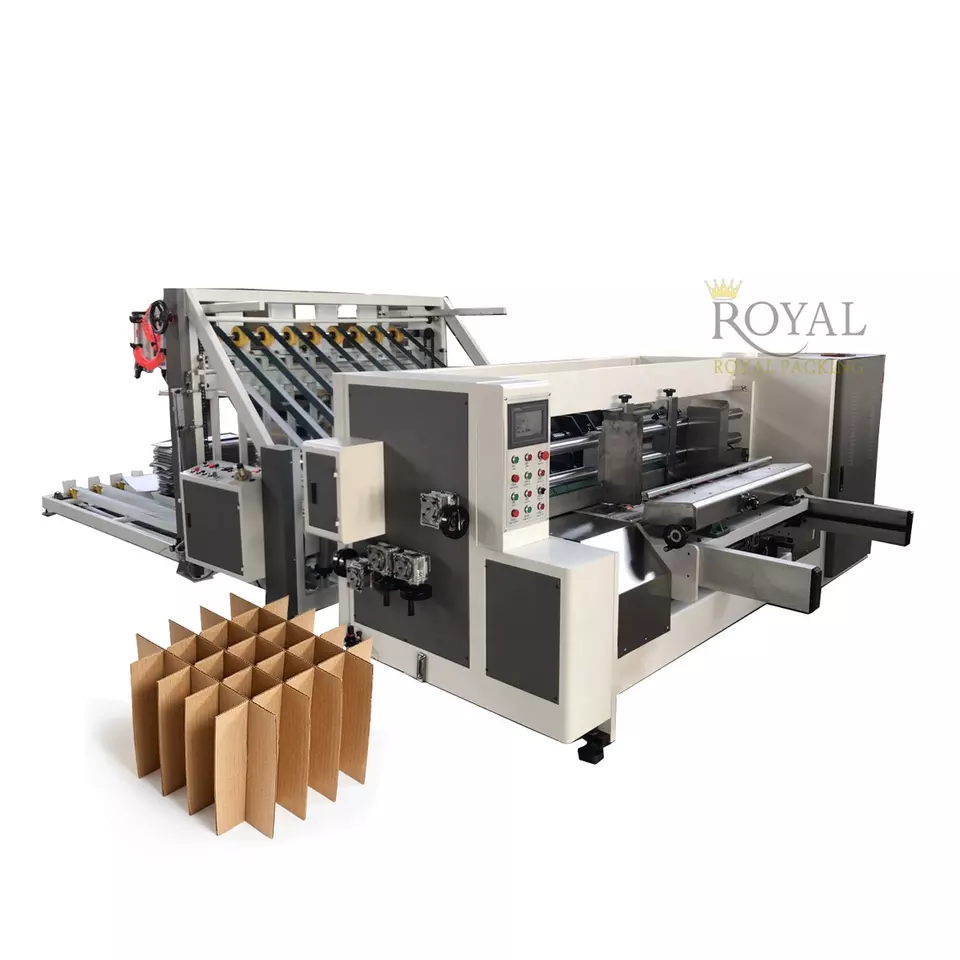

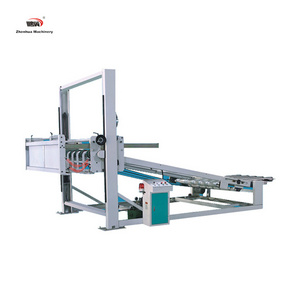

MJKC-1 Automatic Feeding Slotting & Stacker

This machine adopts the vacuum adsorption auxiliary leading edge feeding system feeding mode. Automatic feeder.

It has the function of slotting, chamfering, dividing edge and rolling line of corrugated board at one time. The machine and

slotting depth are all electrically adjusted, and the scale reading is attached. The slotted phase adjustment mechanism is a planetary gear structure, which adopts an electric computer-type 360-degree adjustment, and the upper and lower slotted cutter heads and the pressure roller are synchronously moved left and right. (Note: special tools adjust the left and right movement), which is convenient to use and maintain, small and exquisite, It is a professional equipment for slotting and forming small cartons.

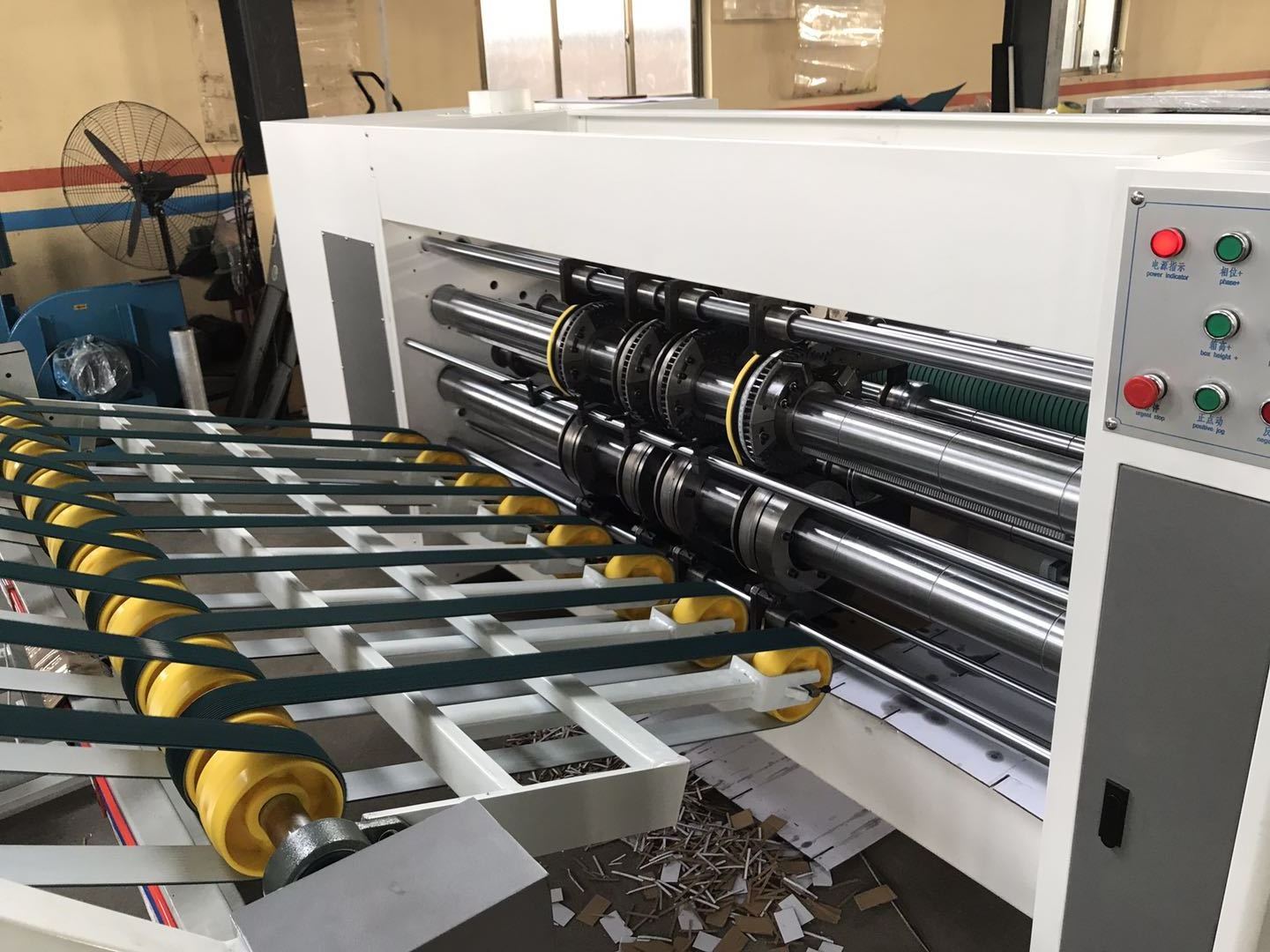

1. The slotting blade head is made of all-steel parts. The slotted cutter adopts a sawtooth curved semicircular cutter to cut the chip and remove the chip. After the slotting is completed, the cardboard enters the paper separation shaft, and the paper separator cuts the two sides of the carton neatly. (Note: The pressure roller and the paper cutter are installed on the same axis for easy adjustment.)

2. After the cardboard slotting, chamfering, pressing line and dividing edge are completed, it is exported by the six conveying shafts of the paper exiting part of the equipment,

3. This machine is equipped with a frequency converter (can be adjusted freely and slowly).

It has the function of slotting, chamfering, dividing edge and rolling line of corrugated board at one time. The machine and

slotting depth are all electrically adjusted, and the scale reading is attached. The slotted phase adjustment mechanism is a planetary gear structure, which adopts an electric computer-type 360-degree adjustment, and the upper and lower slotted cutter heads and the pressure roller are synchronously moved left and right. (Note: special tools adjust the left and right movement), which is convenient to use and maintain, small and exquisite, It is a professional equipment for slotting and forming small cartons.

1. The slotting blade head is made of all-steel parts. The slotted cutter adopts a sawtooth curved semicircular cutter to cut the chip and remove the chip. After the slotting is completed, the cardboard enters the paper separation shaft, and the paper separator cuts the two sides of the carton neatly. (Note: The pressure roller and the paper cutter are installed on the same axis for easy adjustment.)

2. After the cardboard slotting, chamfering, pressing line and dividing edge are completed, it is exported by the six conveying shafts of the paper exiting part of the equipment,

3. This machine is equipped with a frequency converter (can be adjusted freely and slowly).

|

Model

|

|

MJKC-2200

|

MJKC-1800

|

|

|

Max machine speed

|

|

80 ~ 150 pieces/min

|

80 ~ 150 pieces/min

|

|

|

Max feeding size (L * W)

|

|

2200*880mm

|

1800mmX600mm

|

|

|

Min feeding size (L * W)

|

|

600*230mm

|

450mmX170mm

|

|

|

Min slotting interval

|

Negative knife (A * B)

|

175mmX60mm

|

150mmX50mm

|

|

|

|

Positive knife (A * B)

|

90mm*90mm

|

80mmX80mm

|

|

|

Min height of box (H)

|

|

115mm

|

70mm

|

|

|

Machine size

|

|

4.7*4.5*2m

|

2.8*2.5*2.0m

|

|

✦How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us.

✦Does the machine can be customized according to my requirements ?

Sure, we have a strong technical team and have rich experience. Our goal is to make you satisfied.

✦Can you arrange the shipment for me ?

We can arrange the shipment for our clients by sea or by air. Trading terms FOB, CIF, EXW are available.

We will deliver English manual and video with the machine to you. If you still need our help, please contact us.

✦Does the machine can be customized according to my requirements ?

Sure, we have a strong technical team and have rich experience. Our goal is to make you satisfied.

✦Can you arrange the shipment for me ?

We can arrange the shipment for our clients by sea or by air. Trading terms FOB, CIF, EXW are available.

Hot Searches