- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhengxia

-

Dimension(L*W*H):

-

2200x3200x3700

-

Weight:

-

2000 KG

-

Product name:

-

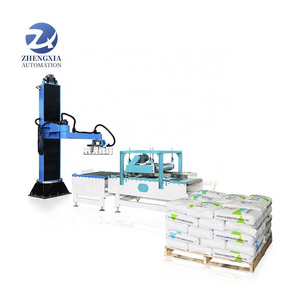

Palletizer Machine Packaging Line Cement Bags Palletizer Robot

-

Function:

-

Automatic Packaging Line, Palletizering line

-

Keywords:

-

Robot Palletizer Packing Line Palletizer

-

Material:

-

Carbon Steel

-

Speed:

-

600-1000pcs/hour

-

After-sales Service Provided:

-

Provided

-

Certification:

-

CE

-

Applicable Product:

-

Box, Case, Bags

Quick Details

-

Application:

-

Food, Beverage

-

Packaging Material:

-

Plastic, Paper, Wood

-

Voltage:

-

220/380V OR CUSTOMIZED

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhengxia

-

Dimension(L*W*H):

-

2200x3200x3700

-

Weight:

-

2000 KG

-

Product name:

-

Palletizer Machine Packaging Line Cement Bags Palletizer Robot

-

Function:

-

Automatic Packaging Line, Palletizering line

-

Keywords:

-

Robot Palletizer Packing Line Palletizer

-

Material:

-

Carbon Steel

-

Speed:

-

600-1000pcs/hour

-

After-sales Service Provided:

-

Provided

-

Certification:

-

CE

-

Applicable Product:

-

Box, Case, Bags

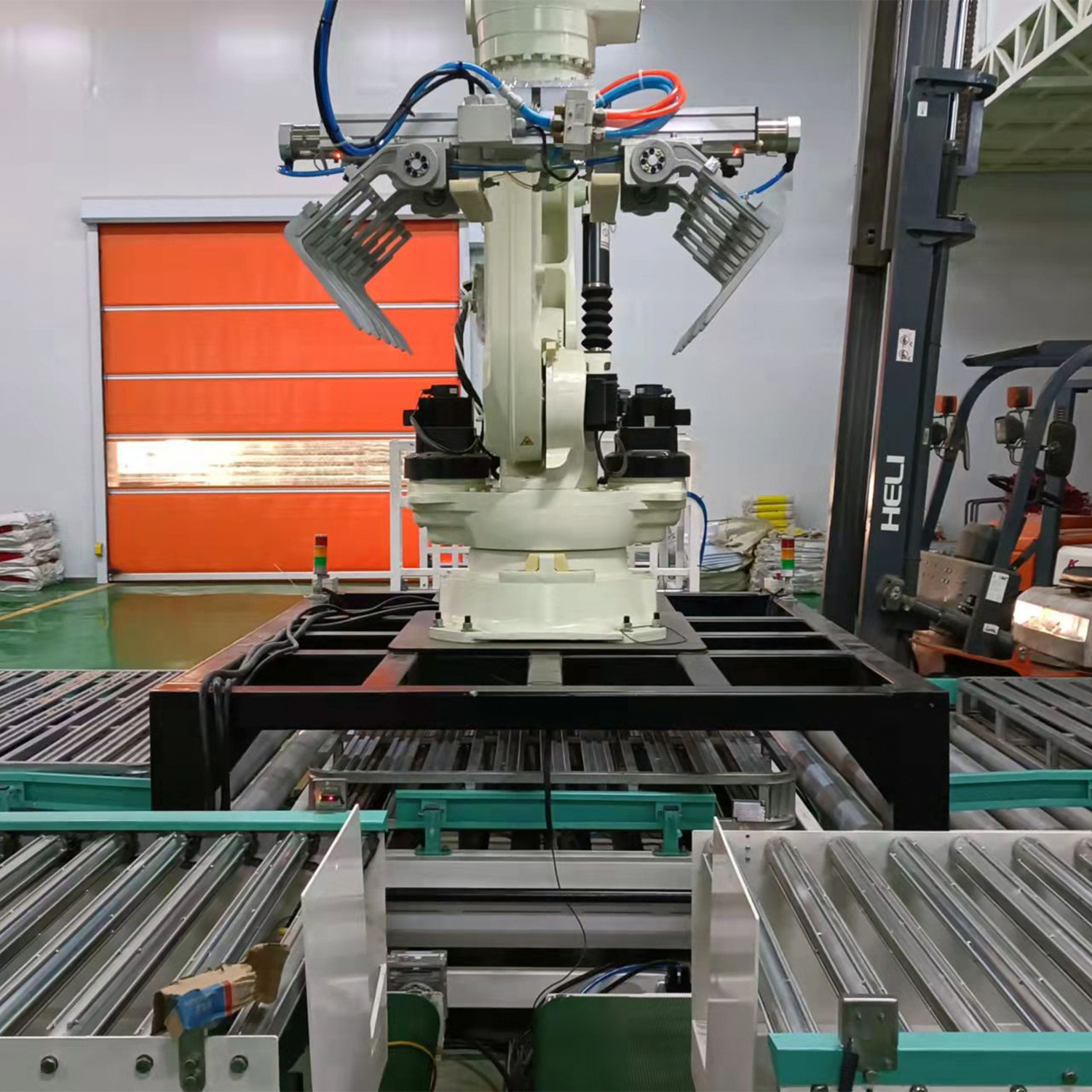

MACHINE SHOW

Features:

1. Touch-screen operation is used to realize human-machine interaction, which can display production speed, cause and location of

faults, and has a high degree of automation. The use of PLC programmable sorting cartons of stacking layers, pallet supply and

discharge can be programmed into the control.

2. Stacking method is easy and simple to adjust and can be performed on the touch screen.

3. Stacking is stable and efficient, which can greatly save labor.

4. The pallet storage has a large capacity and can hold 10-12 empty pallets. It can realize automatic pallet supply.

5. Several stacking methods can be completed without replacing stacking parts.

faults, and has a high degree of automation. The use of PLC programmable sorting cartons of stacking layers, pallet supply and

discharge can be programmed into the control.

2. Stacking method is easy and simple to adjust and can be performed on the touch screen.

3. Stacking is stable and efficient, which can greatly save labor.

4. The pallet storage has a large capacity and can hold 10-12 empty pallets. It can realize automatic pallet supply.

5. Several stacking methods can be completed without replacing stacking parts.

|

Brand

|

Zhengxia Brands

|

|

Palletizer speed

|

600~1000 bags/hr

|

|

Workable bag weights

|

from 1 to 50 kg or

customized needs

|

|

Stacking Type

|

5/6/7/8/9/10/11/12 bags per layer or customized

|

|

Voltage

|

380 V 50 HZ or Customized

|

|

Working Temperature

|

-20~50℃

|

|

Air Pressure

|

0.5-0.7 Mpa

|

|

Application

|

bags, cases, boxes, bottles, barrels

|

1.Free CAD drawing design

2.Provide teaching services

3.Provide on-site installation services

4.Provide one year warranty

5.Machine LOGO and color can be customized

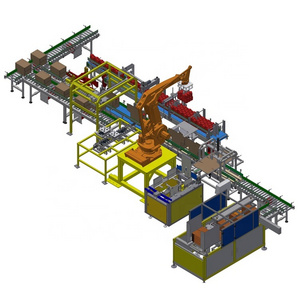

PRODUCT DETAILS

Bag Kicker

Standing bags are transported to this position, and through the detection of photoelectric switches, it is judged whether the bag has reached the position of pushing the bag. After arriving, the cylinder works and kicks the bag down to a horizontal state and transports it to the Incline Conveyor.

Incline Conveyor

The Incline conveyor is mainly used for the transportation of the product. Inclined conveying makes the material inside the bag flat, ready for the next step of shaping and at the same time play the role of cache packing bags .

Bag Flattener

The bag is shaped and flattened by the square roller vibrating conveyor , so that the stacking shape is neat and secure,The shaping conveyor can open a certain distance between the products, which is convenient for photoelectric detection and subsequent palletizing.

Roller Conveyor

The bag is conveyed to the Roller Conveyor, the sensors on both sides will detect the bag, stop the conveying and link the palletizer to grab the bag.

MACHINE COMPONENTS

PROJECT SHOW

COMPANY PROFILE

PACKAGING & DELIVERY

CONTACT US

FAQ

Q1: Can your packing machine be customized according to our requirements?

A1: Yes, of course. We can make customized production according to your requirements, such as color, configuration, logo and so on.

Q2: How to choose suitable packaging machine?

A2: Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How long is the warranty on your packing machine?

A3: We will provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will provide free replacement. If the warranty is exceeded, the damaged spare parts will be provided to you at the cost price. At the same time, our packaging machine adopts brand components such as Schneider, AirTAC, etc., more stable and long life time, so please do not worry about the quality, you can trust us.

Q4: Can you provide after-sales service for installation?

A4: Yes. Packaging equipment before sent to you will installation and commissioning in our factory to make sure that all

components work stable, then the whole device packed in the wooden case/container, when you received the equipment do not need a lot of installation and debugging, at the same time, we will provide the corresponding image/video/manual and online phone call if you have any questions.

If you need to send engineers to the local installation, commissioning and training staff, we can also provide.We will provide nmanuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Q5: What's your payment way?

A5: T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, or L/C.

A1: Yes, of course. We can make customized production according to your requirements, such as color, configuration, logo and so on.

Q2: How to choose suitable packaging machine?

A2: Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How long is the warranty on your packing machine?

A3: We will provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will provide free replacement. If the warranty is exceeded, the damaged spare parts will be provided to you at the cost price. At the same time, our packaging machine adopts brand components such as Schneider, AirTAC, etc., more stable and long life time, so please do not worry about the quality, you can trust us.

Q4: Can you provide after-sales service for installation?

A4: Yes. Packaging equipment before sent to you will installation and commissioning in our factory to make sure that all

components work stable, then the whole device packed in the wooden case/container, when you received the equipment do not need a lot of installation and debugging, at the same time, we will provide the corresponding image/video/manual and online phone call if you have any questions.

If you need to send engineers to the local installation, commissioning and training staff, we can also provide.We will provide nmanuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Q5: What's your payment way?

A5: T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, or L/C.

Hot Searches