- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YH

-

Voltage:

-

380-440V

-

Dimension(L*W*H):

-

3690(L)X2680(W)X2600(H)

-

Power (kW):

-

110

-

Weight (T):

-

2

-

product name:

-

300 Model Metal Small Plastic Shredder Machine

-

Material:

-

Stainless Steel

-

After-sales Service Provided4:

-

Field maintenance and repair service

Quick Details

-

Max.Production Capacity (kg/h):

-

17000

-

Place of Origin:

-

Shandong, China

-

Production Capacity (kg/h):

-

1000 - 1500 kg/h

-

Brand Name:

-

YH

-

Voltage:

-

380-440V

-

Dimension(L*W*H):

-

3690(L)X2680(W)X2600(H)

-

Power (kW):

-

110

-

Weight (T):

-

2

-

product name:

-

300 Model Metal Small Plastic Shredder Machine

-

Material:

-

Stainless Steel

-

After-sales Service Provided4:

-

Field maintenance and repair service

Product Overview

Efficient factory direct supply tire shredder prices for sale

1. shredding mode Shear type crushing, can break flexible and hard materials, low noise, low dust

2. Blade material Wear resistant steel DILLIDUR550

3. Blade Installation The internal control of the tool and the spindle surface adopt the hexagonal design to ensure the good torque transmission and realize the rapid disassembly and assembly of the tool principal axis

4. High strength 42crmov modulation manufacturing, precision grinding

5. Sealing Bearing four seal protection design, effective dust and water proof, prolong the service life of bearing, can be in high temperature dust and open air environment for production and rigid work

FEATURES AT A GLANCE

Scope of work

metallic material:

Aluminum, non-ferrous metals, non-ferrous metals, metal barrels, scrap motorcycles, automobiles, steel bars, briquettes, etc.

Plastic:

Plastic buckets, bulk plastics, plastic films, etc.

Waste paper:

Carton, book paper, impurities, paper tube, waste paper briquetting, etc.

Electronic appliances:

Circuit boards, wires, all kinds of used appliances, etc.

wood:

Pallets, packing boxes, wooden boxes, all kinds of waste furniture, etc.

rubber:

Used tires, rubber sheets, rubber scraps, etc.

film:

Woven bags, ton bags, plastic greenhouses, food bags, packaging bags, etc.

PRODUCT SPECIFICATIONS

|

Model

|

Motor

|

Reducer

|

No of Rotary blades (pcs)

|

Output

|

|

YH-600

|

11kw*2

|

500*2

|

20

|

500~600(kg/h)

|

|

YH-800

|

18.5kw*2

|

500*2

|

26

|

700~800(kg/h)

|

|

YH-1000

|

30kw*2

|

600*2

|

34

|

900~1200(kg/h)

|

|

YH-1200

|

37kw*2

|

750*2

|

40

|

1500~2000(kg/h)

|

|

YH-1500

|

45kw*2

|

850*2

|

50

|

3000~4000(kg/h)

|

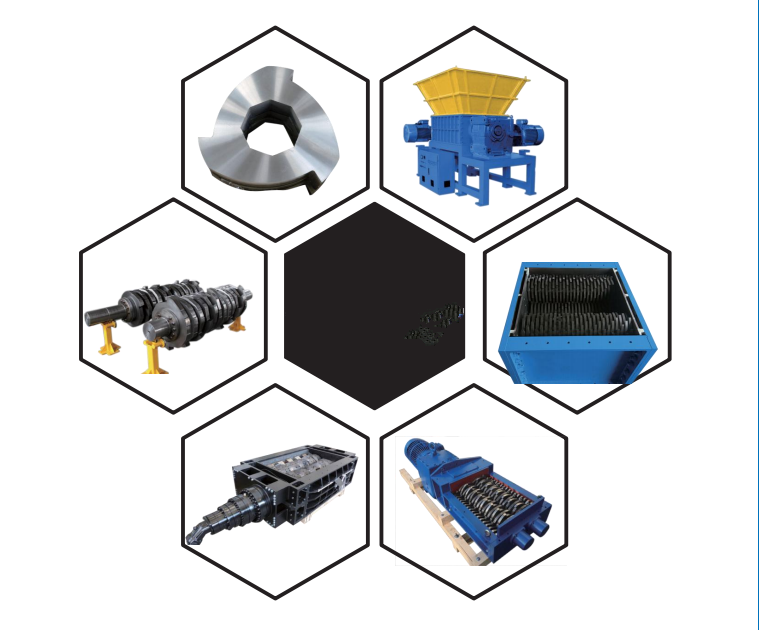

PRODUCT CONFIGURATION

Successful Project

Certifications

SALES AND SERVICE NETWORK

Twin shaft shredder operation manual

1. Basic principles of shredder operation:

Regardless of the reason, the host must be started without load.

2. Preparation before starting:

1). The motor outlet is connected to the wiring of the electric control cabinet according to the serial number marked on the end of the wire. (If the device is in reverse state after connecting the wires, turn off the power and adjust the position of any two wires in the three-phase electricity)

2). The N220 intermediate gear oil must be added before the reducer works, and the addition amount is two-thirds of the oil meter.

3. The principle of starting the shredding system:

1). Start the peripheral equipment first and then the main equipment.

2). Start the auxiliary equipment first and then the processing equipment.

4. Boot procedure:

Electronically controlled start switch, it can start feeding after one minute of idling operation and checking if the equipment is normal.

production process control:

1). After the shredder is started, check the pointer of the ammeter. When the pointer of the ammeter returns from the maximum value to the minimum value, the material will start to feed. Each start mode must ensure that the shredder host operates normally after the current is stable before feeding.

2). Gradually increase the feeding amount according to the main motor current until the main motor current reaches and stabilizes at 85%-95% of the rated value.

3). Pay attention to the change of current at any time during the crushing process, and adjust the feeding amount in time to ensure the best load.

4). In the process of operation, the warehouse inspector checks the size of the crushed materials at any time, and stops the machine for inspection if there is an abnormality.

5). It is strictly forbidden to climb up the shredding equipment body during the crushing process.

6). During the normal production process, the belt protective cover must not be opened to prevent accidents.

7). If abnormal noise and violent vibration are found during the working process, you should stop feeding, cut off the power supply, press the emergency stop switch of the shredder, and check after the rotor is safely stopped, remove the fault, and pull out the emergency stop switch when restarting.

8). If the material is changed and crushed, the materials in the shredder must be exhausted and the batching bin must be replaced before feeding and crushing;

Shutdown

1. After stopping, check the shredder and solve the problem in time.

2). After shutting down, clean up the equipment and sanitation work around the equipment.

3). Pack up tools and materials, and store them at designated locations.

4). Carefully fill in the smashing work record and do a good job of handover.

FAQ

1 how long is the product warranty period ?

A: the product warranty period is 12 months

2. I am a foreign customers, if the machine works wrong, how your company resolved ?

A: We have professional engineers abroad, after receiving your request, we will solve your problems at first time.

3. how much is MOQ of your machine?

A:our machines MOQ is 1 set and also support the mixed batch.

4.Where can we buy the machine's parts?

A: Our company can provide machines for your any time

A: the product warranty period is 12 months

2. I am a foreign customers, if the machine works wrong, how your company resolved ?

A: We have professional engineers abroad, after receiving your request, we will solve your problems at first time.

3. how much is MOQ of your machine?

A:our machines MOQ is 1 set and also support the mixed batch.

4.Where can we buy the machine's parts?

A: Our company can provide machines for your any time

Hot Searches