- Product Details

- {{item.text}}

Quick Details

-

Power:

-

800

-

Dimension(L*W*H):

-

440*510*480mm

-

Weight:

-

28 KG

-

Machinery Function:

-

chocolate melting

-

Name:

-

chocolate enrobing machine

-

Material:

-

Stainless Steel 304

-

Power Source:

-

Electric

-

Advantage:

-

Easy Operation High Performance

-

Capacity:

-

8-60kg

-

Pot quantity:

-

1 pot/2 pot

-

Function:

-

Chocolate Melting Tempering Coating Machine

-

Suitable for:

-

Chocolate Products Making

-

Processing:

-

Melting-tempering-depositing

-

Type:

-

Electric Heating

Quick Details

-

Brand Name:

-

Orange mech

-

Place of Origin:

-

Henan, China

-

Voltage:

-

110/220-240V

-

Power:

-

800

-

Dimension(L*W*H):

-

440*510*480mm

-

Weight:

-

28 KG

-

Machinery Function:

-

chocolate melting

-

Name:

-

chocolate enrobing machine

-

Material:

-

Stainless Steel 304

-

Power Source:

-

Electric

-

Advantage:

-

Easy Operation High Performance

-

Capacity:

-

8-60kg

-

Pot quantity:

-

1 pot/2 pot

-

Function:

-

Chocolate Melting Tempering Coating Machine

-

Suitable for:

-

Chocolate Products Making

-

Processing:

-

Melting-tempering-depositing

-

Type:

-

Electric Heating

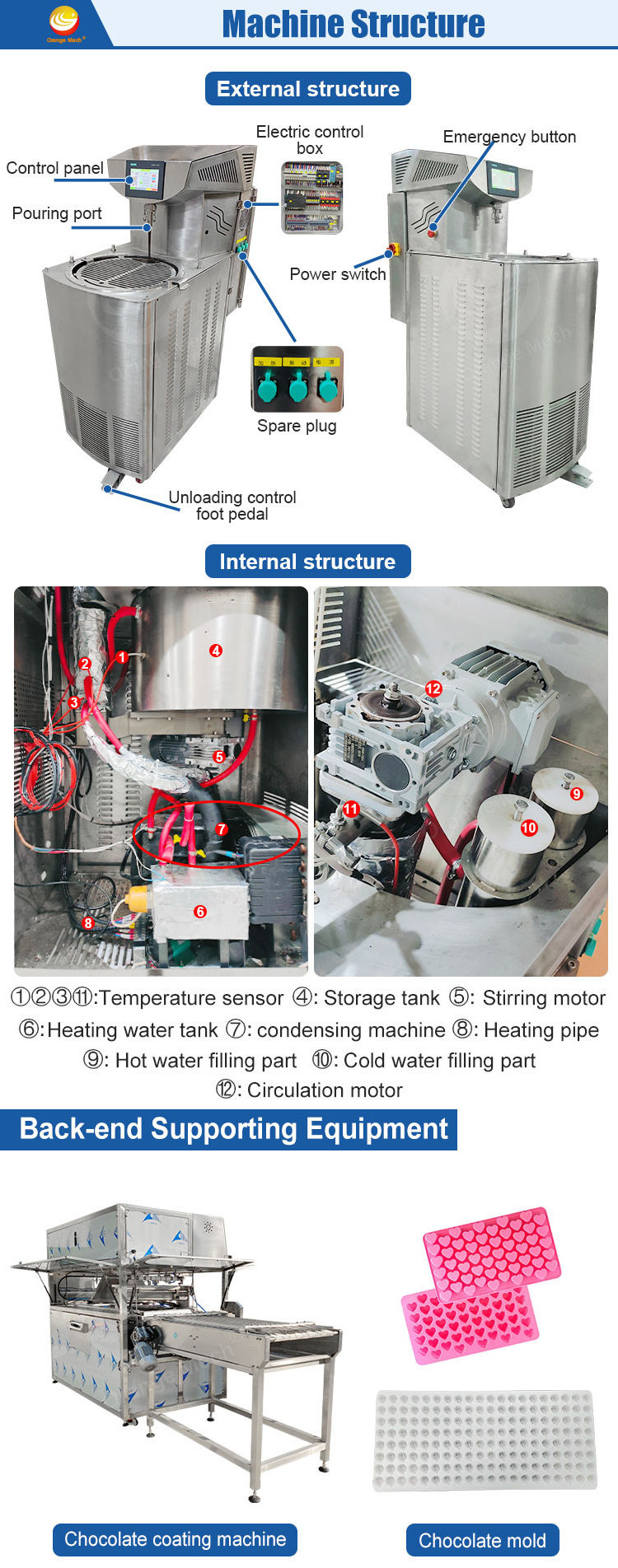

◆ Product Description ◆

Introduction

The chocolate tempering machine consists of a storage tank, a circulation system, a control system and a shell. The working principle of the chocolate tempering machine is to heat and melt the chocolate through the built-in heating device, and continuously circulate the chocolate in the storage tank through the circulation system. At the same time, the temperature is controlled through the control system, so that the chocolate reaches the required temperature and maintains a constant temperature. Warmed chocolate exhibits a better appearance, increases taste and extends shelf life.

Application

Chocolate tempering machine is suitable for bakeries, cafes, ice cream and chocolate candy shops, food processing plants, etc.

Features

1. The machine body is made of stainless steel and is easy to clean. (The whole machine is made of 201 material, and the parts in contact with food are made of 304)

Application

Chocolate tempering machine is suitable for bakeries, cafes, ice cream and chocolate candy shops, food processing plants, etc.

Features

1. The machine body is made of stainless steel and is easy to clean. (The whole machine is made of 201 material, and the parts in contact with food are made of 304)

2.

The electronic control system uses a touch color screen, the control interface has a

manual/automatic switch. According to customer needs, manual operation or the temperature regulator can operate automatically according to the set parameters.

manual/automatic switch. According to customer needs, manual operation or the temperature regulator can operate automatically according to the set parameters.

3.

The control interface has the function of thawing and defrosting materials. When the pipe or

outlet is blocked by chocolate, this function can be used. The cold water pump and hot water pump will heat up at the same time to quickly melt the blocked chocolate.

outlet is blocked by chocolate, this function can be used. The cold water pump and hot water pump will heat up at the same time to quickly melt the blocked chocolate.

4.

The control interface can set the melting temperature and temperature adjustment

temperature. A temperature sensor is installed inside the equipment to monitor the temperature of the equipment in real time.

temperature. A temperature sensor is installed inside the equipment to monitor the temperature of the equipment in real time.

5.

The temperature control machine uses water circulation heating, and uses the mixing/melting function of the storage tank to make the material heated evenly when melted, and the chocolate melts quickly. 6. The temperature regulating machine uses a condensing

compressor for cooling, which has fast cooling speed and accurate temperature regulation. The temperature fluctuation can be controlled at +0.1℃.

7. The control interface is equipped with alarm query, which can query the fault alarm status of the thermostat. After inserting the USB flash drive, the fault timetable can be exported to collect statistics on the equipment failure rate and stability.

compressor for cooling, which has fast cooling speed and accurate temperature regulation. The temperature fluctuation can be controlled at +0.1℃.

7. The control interface is equipped with alarm query, which can query the fault alarm status of the thermostat. After inserting the USB flash drive, the fault timetable can be exported to collect statistics on the equipment failure rate and stability.

8.

The discharge connecting plate under the storage tank is made of one-piece aviation aluminum plate, which has better thermal insulation effect.

9.

A stainless steel baffle is installed above the storage tank to prevent hands from being burned when the machine is running. The round hole baffle under the pouring port will destroy the chocolate molecular structure, and then the chocolate molecular structure will be reorganized in the storage tank, making the taste more delicate when eating.

10.

The outlet of the storage tank is composed of multiple long holes to prevent large pieces of unmelted chocolate from entering the pipe and blocking the pipe, and coating the food surface, affecting the taste.

11.

The mixing blade of the storage tank is made of 5mm stainless steel, which is pollution-free, does not require deformation, and is easy to clean. When cleaning, you can force it upward to take it out.

◆ Specification ◆

|

Model

|

orangemech-CTM--25L

|

orangemech-CTM--60L

|

orangemech-CTM--100L

|

|

Voltage

|

220/380V 50HZ

|

380V 50HZ

|

380V 50HZ

|

|

Power

|

6KW

|

9KW

|

11KW

|

|

Capacity

|

80 kg/h

|

200 kg/h

|

300 kg/h

|

|

Dimension

|

1060*840*1780mm

|

1350*880*1780mm

|

1600*770*1100mm

|

|

Weight

|

314kg

|

360kg

|

430kg

|

◆ Product Details ◆

◆ Recommend Products ◆

Hot Searches