- Product Details

- {{item.text}}

Quick Details

-

Application:

-

rubber powder machine

-

End product:

-

Rubber Particle

-

Function:

-

tires powder grinding machine

-

Capacity:

-

300-800kg/h

-

Usage:

-

Used Tire Recyling

-

Product name:

-

tire shredding machine

-

Color:

-

Customers' Demand

-

Machine Type:

-

Fully Automatically

Quick Details

-

Place of Origin:

-

Henan, China

-

Raw material:

-

Waste Tyre

-

Name:

-

rubber powder grinding machine

-

Application:

-

rubber powder machine

-

End product:

-

Rubber Particle

-

Function:

-

tires powder grinding machine

-

Capacity:

-

300-800kg/h

-

Usage:

-

Used Tire Recyling

-

Product name:

-

tire shredding machine

-

Color:

-

Customers' Demand

-

Machine Type:

-

Fully Automatically

Full automatic waste tire shredding crushing rubber powder grinding machine

Waste rubber powder machine from waste steel wire tire cutting machine, slitting machine, cutting machine, 800 roller mill, double magnetic separator, cyclone feeding machine, screening machine, single magnetic separator This eight-part component is composed. Through the waste tire decomposing equipment QKJ-1200 cutting machine, the tire wire end of the tire is first cut, and then the top and the side of the tire are cut into strips by a slitting machine, and the rubber strip is automatically cut into 3-5 cm squares by the cutting machine.

The cut rubber block is ground in a roller mill, and the double magnetic separator and the single magnetic separator completely separate the steel wire inside the tire from the rubber powder. This circulating grinding process is advanced in technology, does not require any chemical raw materials, and has no exhaust gas. No waste water, low operating cost, is the use of steel wire tires to produce rubber powder equipment.

Application:

Runways, school playgrounds, garden trails, bowling alleys, sidewalks, composite rubber floor tiles, anti-static floor tiles, artificial turf, playgrounds, artificial grass football fields, kindergarten sports venues and casino tennis and basketball courts. Rubber floor tiles, plastic track, lawn quartz sand, cottonseed granules, tennis courts, volleyball courts, golf courses, airplane courts, basketball courts and leisure casinos, EPDM safety mats, gym mats, all kinds of court mats.

Applicable material range:

Used tires: such as bicycles, tractors, inner tubes, tires, water rings, soles, gaskets, rubber factory undercuts, sealing sheets, conveyor belts, etc.

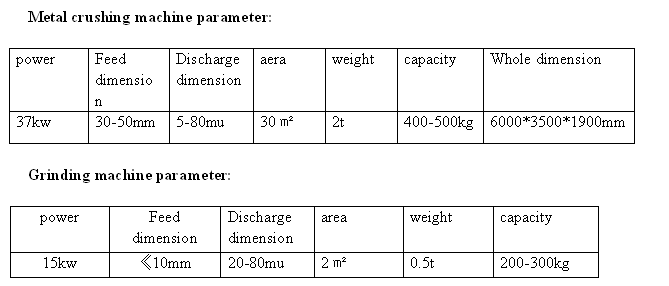

Parameter: