- Product Details

- {{item.text}}

Quick Details

-

PCB width:

-

50-400mm

-

Weight:

-

2200kgs

-

Color:

-

PC white

-

Package:

-

Wooden case packing

Quick Details

-

Weight (KG):

-

2200

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OUBEL

-

PCB width:

-

50-400mm

-

Weight:

-

2200kgs

-

Color:

-

PC white

-

Package:

-

Wooden case packing

Product Description

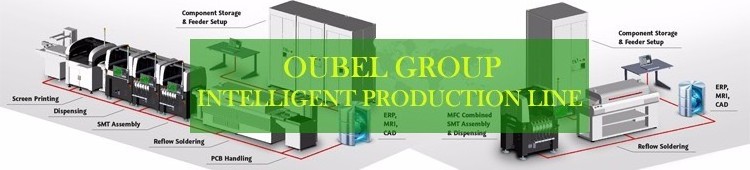

Fully Automatic SMT Production Line for Mobile Phone and LED Light Assembly Machine Line

PCB Magazine Loader:

2.Strong ,firm and stable design.

3.Up&down pneumatic clamps to ensure the magazine rack position.

4.Special gas circuit design to ensure no PCB breakage.

5.With SMEMA signal.

3.Up&down pneumatic clamps to ensure the magazine rack position.

4.Special gas circuit design to ensure no PCB breakage.

5.With SMEMA signal.

|

Model

|

OB-L708

|

|

Dimensions

|

1330*765*1250mm

|

|

Magazine size

|

355*320*563(mm)

|

|

PCB size

|

350*50-250(mm)

|

|

Magazine qty

|

Up 1, down 2

|

|

Weight

|

Approx.140KGS

|

Auto Solder Paste Printer:

2.Image and optical system,applicable for tin plating,coppering ,gold plating,tin spraying,FPC and other types PCB with of different colors,able to ensure high accuracy.

3.Chinese/English operating interface.Adopts windows XP/win7 operation interface with user friendly software.

4.Three cleaning system equipped with three cleaning methods:dry cleaning,wet cleaning,vacuum.

5.High adaptablitty steel mesh frame clamping system,able to print all kinds of size screen frames,and quickly change models during the production line.

6.2D solder paste quality inspection and analysis system,immediately detects solder paste deposition defects such as

deviation,lack paste,miss paste,paste joint etc,and guarantees print quality.

3.Chinese/English operating interface.Adopts windows XP/win7 operation interface with user friendly software.

4.Three cleaning system equipped with three cleaning methods:dry cleaning,wet cleaning,vacuum.

5.High adaptablitty steel mesh frame clamping system,able to print all kinds of size screen frames,and quickly change models during the production line.

6.2D solder paste quality inspection and analysis system,immediately detects solder paste deposition defects such as

deviation,lack paste,miss paste,paste joint etc,and guarantees print quality.

|

Model

|

GSE

|

|

Max. PCB size

|

400*340mm

|

|

Max. Frame Size

|

737*737 mm

|

|

Cycle Time

|

<8.5s ( exclude printing & cleaning time)

|

|

Compressed air

|

4~6 Kgf/cm2

|

|

Power Input

|

AC 220V±10%, 50/60Hz, Single Phase

|

|

Dimensions

|

1158(L)×1362(W)×1463(H)mm

|

|

Weight

|

Approx.1000kg

|

HanWha Pick And Place Machine:

2.The highest applicability to long and large PCBs among machines of the same class;

3.Easy component registration;

4.Mixed use of Electric feeder and pneumatic feeder;

5.Components monitoring before/after placement;

6.Panorma view function;

7.Multi-Vendor component management function.

3.Easy component registration;

4.Mixed use of Electric feeder and pneumatic feeder;

5.Components monitoring before/after placement;

6.Panorma view function;

7.Multi-Vendor component management function.

|

Model

|

SM481 Plus

|

|

Alignment

|

Flying Vision+stage vision (Option)

|

|

Spindles

|

6 Spindles ×1 Gantry

|

|

Placement Speed

|

40,000CPH(Optimum)

|

|

Placement Accuracy

|

±40μm@μ±3σ

|

|

Applicable PCB

|

Max. 460(L) x 400(W)(Standard)

|

|

Dimension

|

1650×1680×1530MM

|

|

Weight

|

Approx. 1655KGS

|

8 Zones Reflow Oven:

2. Windows7 operation interface, powerful and easy to operate.

3. The upper furnace body is opened by an automatic cylinder jacking machine, and is equipped with a safety support rod to ensure safety and reliability.

4. The mesh belt tensioning device is equipped to ensure smooth transportation of PCB without shaking and deformation; Synchronous guide rail transmission mechanism (online connection with automatic Mounter) to ensure accurate guide rail width adjustment and long service life.

5.All heating zones are PID controlled by computer (the upper and the lower heating zone are subject to independent temperature control, and the sub heating zone can be opened separately. District heating can be used to reduce the starting power).

6.Mesh belt transmission and guide rail is fully closed-loop controlled by computer, which can meet the simultaneous production of different types of PCBs.

7. It is equipped with fault audible and visual alarm function and leakage protector to ensure the safety of operators and control system.

|

Model

|

OB-HF0802-LF

|

|

Heating zone quantity

|

Up 8 down 8

|

|

Heating zone length

|

3500mm

|

|

PCB size

|

50-350mm

|

|

Transport method

|

Mesh belt + Guide rail

|

|

Applicable solder type

|

Lead free solder / lead solder

|

|

Power

|

3Φ、380V、50HZ

|

|

Start up power

|

38KW

|

|

Working power

|

8KW

|

|

Dimensions

|

5400*1370*1555mm

|

|

Weight

|

2000kg

|

PCB Magazine Unloader:

2. PLC+ touch screen controller, user friendly "soft touch "LED control panel is optional;

3.Up&down pneumatic clamps to ensure the magazine rack position.

4.Special gas circuit design to ensure no PCB breakage.

5.With SMEMA signal.

3.Up&down pneumatic clamps to ensure the magazine rack position.

4.Special gas circuit design to ensure no PCB breakage.

5.With SMEMA signal.

|

Model

|

OB-UL718

|

|

Dimensions

|

1730*765*1250mm

|

|

Magazine size

|

355*320*563(mm)

|

|

PCB size

|

350*50-250(mm)

|

|

Magazine qty

|

Up 1, down 1

|

|

Weight

|

Approx.160KGS

|

Related Product

Packing&Delivery

Hot Searches