- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

9000

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

NHN

-

Spinning Method::

-

Rotor Spinning

-

After-sales Service Provided:

-

1 Year online service

-

Name:

-

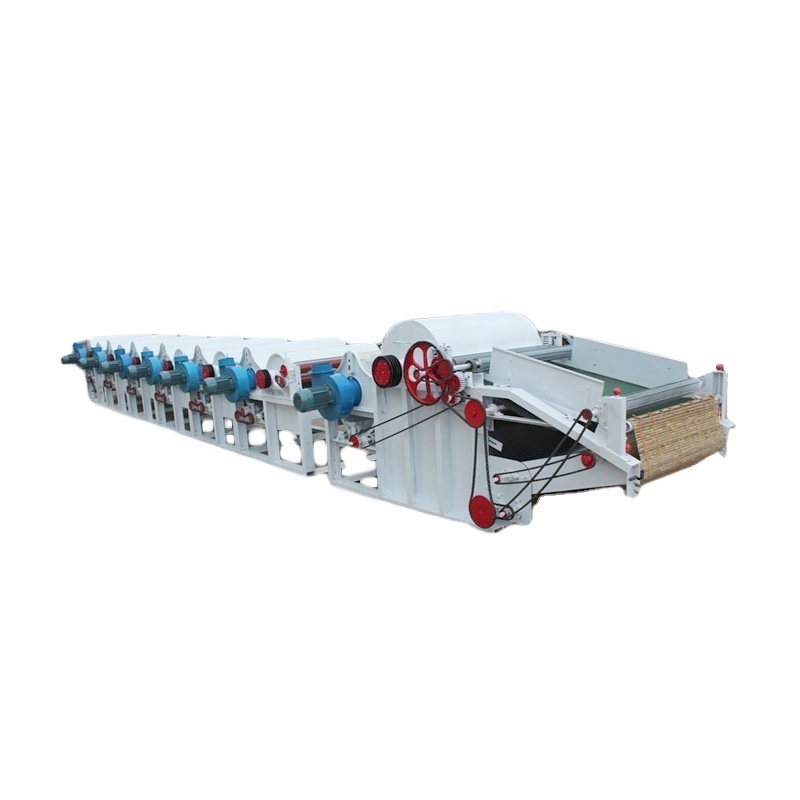

Fiber Recycling Machine

-

Application:

-

Textile Industry

-

Function:

-

Recycling Waste Cotton Fabric

-

Keywords:

-

Waste Fabric Recycling Machine

-

Raw material:

-

Waste Clothing

-

Capacity:

-

180-220 Kg/hr

-

KW:

-

1000kw

-

Color:

-

Customizable

Quick Details

-

Machine Type:

-

Textile Recycling

-

Product:

-

farbic

-

Material Capabilities:

-

Thread

-

Weight (KG):

-

9000

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

NHN

-

Spinning Method::

-

Rotor Spinning

-

After-sales Service Provided:

-

1 Year online service

-

Name:

-

Fiber Recycling Machine

-

Application:

-

Textile Industry

-

Function:

-

Recycling Waste Cotton Fabric

-

Keywords:

-

Waste Fabric Recycling Machine

-

Raw material:

-

Waste Clothing

-

Capacity:

-

180-220 Kg/hr

-

KW:

-

1000kw

-

Color:

-

Customizable

Product description

1.

This machine is with domestic leading technology, superfine new tearing machine for textile waste, which are with porcupine roller with diameter 600-1300 mm, each cylinder with difference angle and specifications taper-pins, the feeding all adopted elastic rubberized roller with diameter 250 mm. The working width from 1000-1300 mm and the maximum capacity up to 150-180 kg/h,

2.

the Opening machine is mainly used for chemical fiber, textile waste, waste yarn, waste.

The machine is processing old quilt, cloth angel, scrap yarn, ideal for linen and other items.

3.

The opening machine synthesizes kinds of processing machinery characteristics and advanced experience of design and manufacture.It was identified that the machine basically reached the high quality, low consumption requirement, and have model compact, easy operation, safety.

4,This machine is a high-speed operation licker centrifugal force generated to exclude the mechanical cotton material

impurities and tear loose.

1.The recycling machine, can recycle kinds of textile raw materials such as the fabric waste, cotton waste, the fiber waste,etc

2.The machine can open & loose the material as well as remove the impurities through the centrifugal force generated by the high-speed rotation of the roller.

3.The length of the fiber can be kept and reduce the harm to the fiber

4.The suitable machine model affected by the raw material and the quality needed

2.The machine can open & loose the material as well as remove the impurities through the centrifugal force generated by the high-speed rotation of the roller.

3.The length of the fiber can be kept and reduce the harm to the fiber

4.The suitable machine model affected by the raw material and the quality needed

Product Paramenters

|

Model

|

Recycling line GM600N+6*GM250N

|

|

Installation dimensions

|

15110mm*2010mm*3050

|

|

Weight

|

7550KG

|

|

Total power

|

75KW

|

|

Working width

|

1040mm/ Unadjustable

|

|

Dust removal system

|

By fans to out of workshop

|

|

Way of control

|

Constant power & All Inverter control &PLC

|

|

Bearing

|

KOY0/Or according to the customer's requirements

|

|

PLC

|

MITSUBISHI

|

|

Print Color

|

According to the customer's requirements

|

Product features

Main working principle

1.Under the help of the centrifugal force generated by the high-speed rotation for the roller, loose & open the big raw material into small pieces.

2.Under the help of the cleaning machine, the small pieces can be processed into cotton, and keep the length of the fiber.

3.Under the help of the Laura, then the extra feeding of the textile material can be controlled

Together with the ballet pulley and gear, the machine can be operated by the electric motor

1.Under the help of the centrifugal force generated by the high-speed rotation for the roller, loose & open the big raw material into small pieces.

2.Under the help of the cleaning machine, the small pieces can be processed into cotton, and keep the length of the fiber.

3.Under the help of the Laura, then the extra feeding of the textile material can be controlled

Together with the ballet pulley and gear, the machine can be operated by the electric motor

Associated Products

Product Delivery

Hot Searches