- Product Details

- {{item.text}}

Quick Details

-

Power:

-

140w/180w/250w

-

Dimension(L*W*H):

-

2160*600*1780mm

-

Weight:

-

150 KG

-

Product name:

-

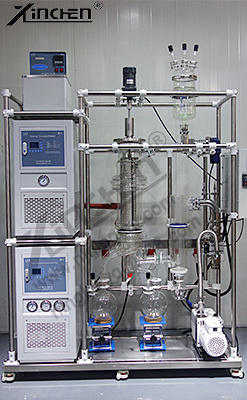

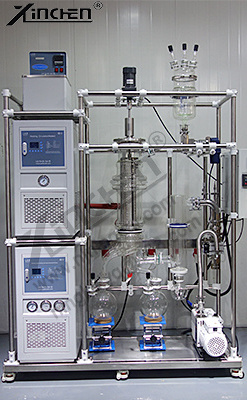

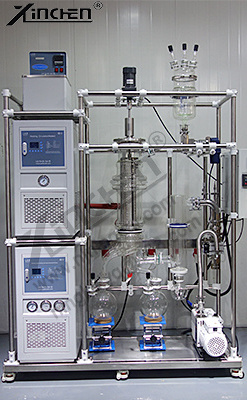

Molecular Distillation Equipment

-

Glass Material:

-

High Borosilicate 3.3

-

Frame material:

-

Stanless Steel

-

Heating method:

-

Thermal Oil Heating

-

Rotating Speed:

-

Max 500rpm

-

Optional:

-

Explosion Proof PLC system Metering pump

-

Barrel size:

-

60 /80 /100 /150/ 200 mm

-

Effective area:

-

0.05/0.1/0.15/0.25/0.4 square meter

-

Motor power(W):

-

140/180/250w

-

Condensation Area:

-

0.03/0.25/0.3/0.4/0.5 square meter

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINCHEN

-

Voltage:

-

220V50-60Hz

-

Power:

-

140w/180w/250w

-

Dimension(L*W*H):

-

2160*600*1780mm

-

Weight:

-

150 KG

-

Product name:

-

Molecular Distillation Equipment

-

Glass Material:

-

High Borosilicate 3.3

-

Frame material:

-

Stanless Steel

-

Heating method:

-

Thermal Oil Heating

-

Rotating Speed:

-

Max 500rpm

-

Optional:

-

Explosion Proof PLC system Metering pump

-

Barrel size:

-

60 /80 /100 /150/ 200 mm

-

Effective area:

-

0.05/0.1/0.15/0.25/0.4 square meter

-

Motor power(W):

-

140/180/250w

-

Condensation Area:

-

0.03/0.25/0.3/0.4/0.5 square meter

Product Description

Short path molecular distillation is a new technique that address the problems that conventional distillation techniques cannot solve . It can achieve liquid to liquid separation at very low vacuum degree according to the mean free path difference of molecular motion under the temperature of much lower than the liquid boiling point . Mainly the use of wiped system forcing liquid film evaporation or distillation of a highly efficient evaporation, distillation equipment , deodorization , degassing reaction and supporting heating , cooling and other unit operations , can be widely used in food , fine chemicals , electronic materials , plastic engineering and polymer purification , etc . The system also can be used to recover organic solvents from industrial effluents , especially for high boiling point , heat-sensitive , easily oxidized material separation and purification .

Product Advantages & Features

1. Operating temperature is far below the boiling point of the material . It has a big advantage in handling the thermal material , bio-acid fat , high boiling point and the materials which is not easy to steam out .

2. Heating time is extremely short , ordinary distillation need to take few hours in the process, but our short path distillation only need few minutes .

3. Low carbon dioxide , environmentally friendly and good for maintaining the material activity.

4. Belong to the physical separation process , can keep the natural state of the material from pollution .

5. Widely used in high value-added materials deodorization , bleaching , purification and separation .

Product Applications

Our short path molecular distillations are widely used in food, fine chemicals , Electronic materials, plastic engineering and polymer (such as polyols, fatty acids, polyphenols, polyurethanes, epoxy resins, milk fat, GMS, flavors and fragrances, heavy oil and paraffin oil) purification and so on. The system can also be used to recover organic solvents from industrial effluents. Especially suitable for high boiling point, heat-sensitive, easily oxidized material separation and purification.

Product Paramenters

|

Product model

|

evaporation tube specifications Φ (mm)

|

Evaporation tube heat transfer area(㎡)

|

Built-in cooling area (㎡)

|

Constant pressure feeding bottle( L)

|

Sample throughput (L/H)

|

Motor power

(W) |

motor speed

(rpm) |

|

NKDF-60

|

60

|

0.05

|

0.03

|

1

|

0.8

|

140

|

800

|

|

NKDF-80

|

80

|

0.1

|

0.25

|

1

|

1.5

|

140

|

800

|

|

NKDF-100

|

100

|

0.15

|

0.3

|

1

|

3

|

180

|

800

|

|

NKDF-150

|

150

|

0.25

|

0.4

|

2

|

5

|

180

|

800

|

|

NKDF-200

|

200

|

0.4

|

0.5

|

3

|

8

|

250

|

800

|

|

NKDF-300

|

300

|

0.6

|

0.8

|

5

|

10

|

250

|

500

|

Details Images

Related products

Customized 20L ultrasonic reactor , 80L three layer reactor with chiller , 10L chemical reactor with PLC control , 30L glass

reactor with 2L manual lift filter reactor , explosion proof three layer lifting reactor , glass distillation reaction device ,

50L lifting filter reactor, 50L double wall multifunctional reactor , 100L explosion proof complete of glass reactor , 20L vacuum suction filter , multifunctioal ultrasonic glass reactor , 200L double layer reactor with tail gas absorption device , 50L distillation column , PLC integrated control reaction device , 50L tail gas absorption device , distillation unit with wiped thin film evaporator , 50L single layer reaction kettle , 30L lifting filter , PLC integrated control reaction device , 1L lab grade rotary evaporator , 5L-50L pilot plant rotavapor , 10L-50L explosion proof evaporator , heating circulator , heating refrigeration circulator , low temperature circulator , ultrasonic cell crusher, super thermalstatic , industrial ultrasonic treatment equipment , hybridization oven , UV cross linker , homogenizer , dry bath , etc .

Recommend Products

We would like to introduce our rotary evaporators and ultrasonic glass reactors to you .

Our factory

Ningkai Instrument Co . Ltd is located in Nanjing , China , where own hundreds of universities and research institutes. And famous as its thousands of years long history culture. Profound culture and strong scientific research strength , provide sustainable and vigorous power for Ningkai development .

Main products include Glass Reactor(single layer, double- layer and three- layer) , Rotary Evaporator , Short Path Molecular

Distillation , Heating Circulators , Heating Refrigeration Circulator , Low Temperature Circulator , Ultrasonic Cell Crusher ,

Industrial Ultrasonic Treatment Equipment , Ultrasonic Cleaning Machine , High(Low) Temperature Constant Temperature Trough , Hybridization Oven , UV Cross-linker , Flap Type Homogenizer , Dry Bath and etc . Ningkai Instrument has exported its products to Europe , South America , North America , Latin America , Asia , Australia , Middle East , Africa and etc . Providing technical support for tens of thousands organizations to solve problems within their research , special for university , research institutes, inspection agencies , industries and etc .

Exhibition and Certification

Group Photos after Overseas Filed Installation and Commission .

CE ISO CERTIFICATES

Glass reactor, rotary evaporator ,short path molecular distillation , temperature control system , water bath etc

FAQ

Q1. What is your terms of payment?

A: T/T 50% as deposit, and 50% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q3. How about your delivery time?

A: Generally, it will take 7 to 10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We also can design for you.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

A: T/T 50% as deposit, and 50% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q3. How about your delivery time?

A: Generally, it will take 7 to 10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We also can design for you.

Q5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Hot Searches