- Product Details

- {{item.text}}

Quick Details

-

Production Capacity (kg/h):

-

200 - 4000 kg/h

-

Brand Name:

-

CAMEL

-

Voltage:

-

380v 50hz 3phase (can customized)

-

Dimension(L*W*H):

-

7000*1800*2300mm

-

Power (kW):

-

85

-

Weight (T):

-

4.3

-

Application:

-

Waste Plastic recycling

-

Raw material:

-

Various Plastic Wood Rubber

-

Type:

-

Shredder and Crusher System

-

Color:

-

Customized Color

-

Final product:

-

Plastic granules/scraps

-

Motor:

-

Siemens Beide/WEG

-

Contactor:

-

Schneider or Siemens

-

Inverter:

-

ABB Delta Holip SINEE

-

PLC:

-

Siemens

-

Bearing:

-

ZWZ NSK

Quick Details

-

Max.Production Capacity (kg/h):

-

4000

-

Place of Origin:

-

Jiangsu, China

-

Machine Type:

-

plastic shredder and crusher system

-

Production Capacity (kg/h):

-

200 - 4000 kg/h

-

Brand Name:

-

CAMEL

-

Voltage:

-

380v 50hz 3phase (can customized)

-

Dimension(L*W*H):

-

7000*1800*2300mm

-

Power (kW):

-

85

-

Weight (T):

-

4.3

-

Application:

-

Waste Plastic recycling

-

Raw material:

-

Various Plastic Wood Rubber

-

Type:

-

Shredder and Crusher System

-

Color:

-

Customized Color

-

Final product:

-

Plastic granules/scraps

-

Motor:

-

Siemens Beide/WEG

-

Contactor:

-

Schneider or Siemens

-

Inverter:

-

ABB Delta Holip SINEE

-

PLC:

-

Siemens

-

Bearing:

-

ZWZ NSK

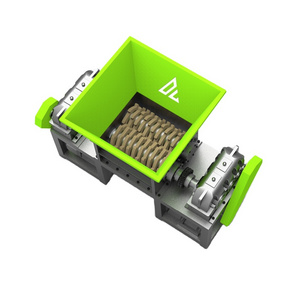

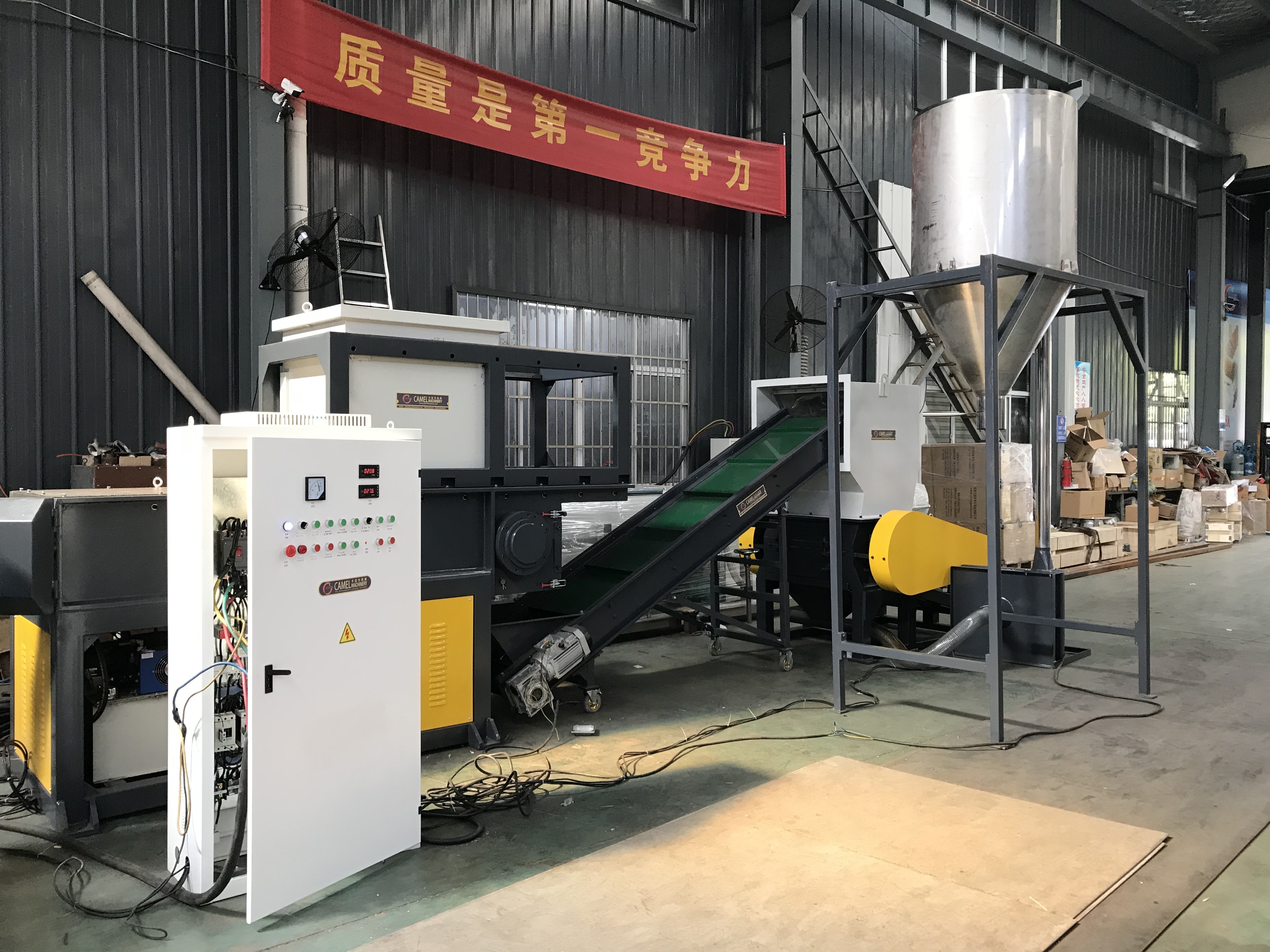

Waste plastic shredder and crusher system

Specifications

plastic shredder machine

1. composed by shredder and crusher

2. suitable big HDPE pipe plastic drum lump

3. heavy duty

General description of plastic shredder machine:

plastic shredder machine is designed for crushing big volume plastic and hard plastic, such as:

plastic drums made of HDPE/PP, HDPE pipe, Plastic lumps, even wood pallets and so on.

plastic shredder machine

1. composed by shredder and crusher

2. suitable big HDPE pipe plastic drum lump

3. heavy duty

General description of plastic shredder machine:

plastic shredder machine is designed for crushing big volume plastic and hard plastic, such as:

plastic drums made of HDPE/PP, HDPE pipe, Plastic lumps, even wood pallets and so on.

Features:

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blades has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5)Each fixed blades has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6)Quiet operation at low speed

7)Screen mesh is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc.

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blades has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5)Each fixed blades has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6)Quiet operation at low speed

7)Screen mesh is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc.

Plastic shredder machine composed by:

1. Single shaft shredder

2. Conveyor

3. Plastic crusher

4. Blow wind system

1. Single shaft shredder

2. Conveyor

3. Plastic crusher

4. Blow wind system

|

Model

|

Power

(kw) |

Number of

rotary knife |

Knife size

(mm) |

Shaft Rotating

diameter (mm) |

Dimension of

crushing chamber (mm) |

Output

(kg/h) |

Weight

(kg) |

|

WD-500

|

18.5

|

28

|

40*40 or 50*50

|

ᴓ280

|

500*550

|

300~500

|

2800

|

|

WD-600

|

22

|

32

|

|

ᴓ280

|

600*650

|

500~600

|

2900

|

|

WD-800

|

45

|

44

|

|

ᴓ350

|

800*850

|

500~800

|

4100

|

|

WD-1000

|

55

|

52

|

|

ᴓ350

|

1000*1050

|

800~1000

|

6500

|

|

WD-1200

|

75

|

68

|

|

ᴓ350

|

1200*1250

|

1000~1200

|

7000

|

|

WD-1500

|

90

|

81

|

|

ᴓ550

|

1500*1600

|

1000~1500

|

10500

|

|

WD-1600

|

110

|

85

|

|

ᴓ550

|

1600*1700

|

1000~1600

|

13800

|

|

Model

|

Motor power

|

Rotating blade

|

Fixing blade

|

Output

|

|

PC600

|

18.5KW or 22KW

|

10 or 30Pcs

|

2Pcs

|

200-300kg/h

|

|

PC800

|

30KW or 37KW

|

10 or 24Pcs

|

4Pcs

|

500-600kg/h

|

|

PC1000

|

55KW

|

10 or 24Pcs

|

4Pcs

|

600-800kg/h

|

|

PC1200

|

75KW

|

10 or 24Pcs

|

4Pcs

|

1000kg/h

|

Packaging and Loading

Recommend Products

Hot Searches