- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 220V/50Hz

-

Dimension(L*W*H):

-

340*220*110mm

-

Power (kW):

-

8 kW

-

Weight (KG):

-

7 KG

-

Name:

-

rubber cutting machine

-

Application:

-

Rubber Processing Machinery

-

Raw material:

-

Titanium

-

Function:

-

tire cutting machine

-

Frequency:

-

40Khz

-

Power:

-

800w

-

Cutting blade width:

-

300mm

-

ultrasonic generator:

-

digital type

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HI-TOO

-

Core Components:

-

generator, Titanium blade

-

Voltage:

-

220V, 220V/50Hz

-

Dimension(L*W*H):

-

340*220*110mm

-

Power (kW):

-

8 kW

-

Weight (KG):

-

7 KG

-

Name:

-

rubber cutting machine

-

Application:

-

Rubber Processing Machinery

-

Raw material:

-

Titanium

-

Function:

-

tire cutting machine

-

Frequency:

-

40Khz

-

Power:

-

800w

-

Cutting blade width:

-

300mm

-

ultrasonic generator:

-

digital type

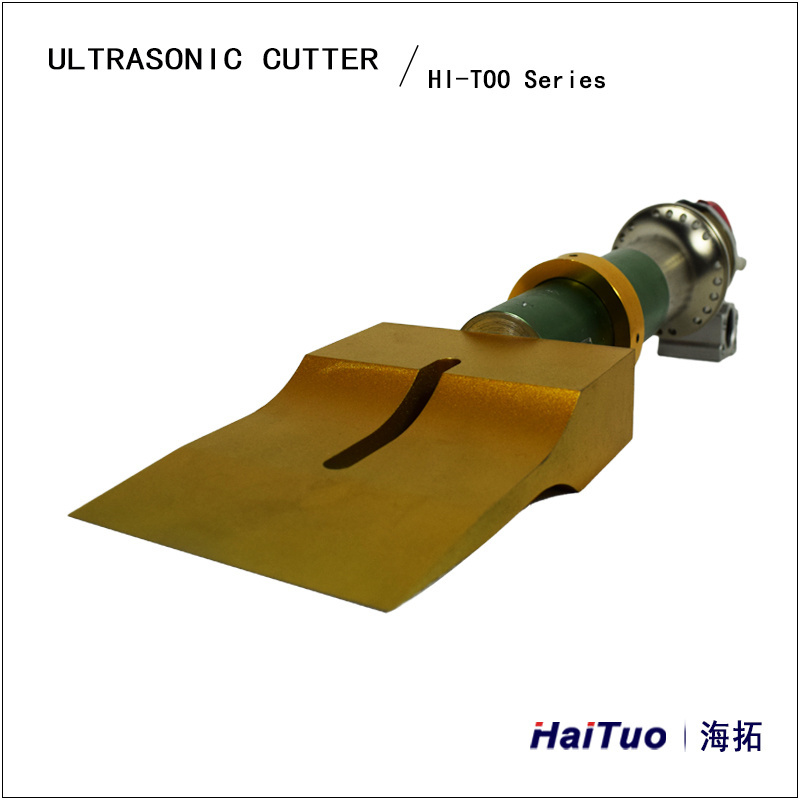

INTRODUCTION

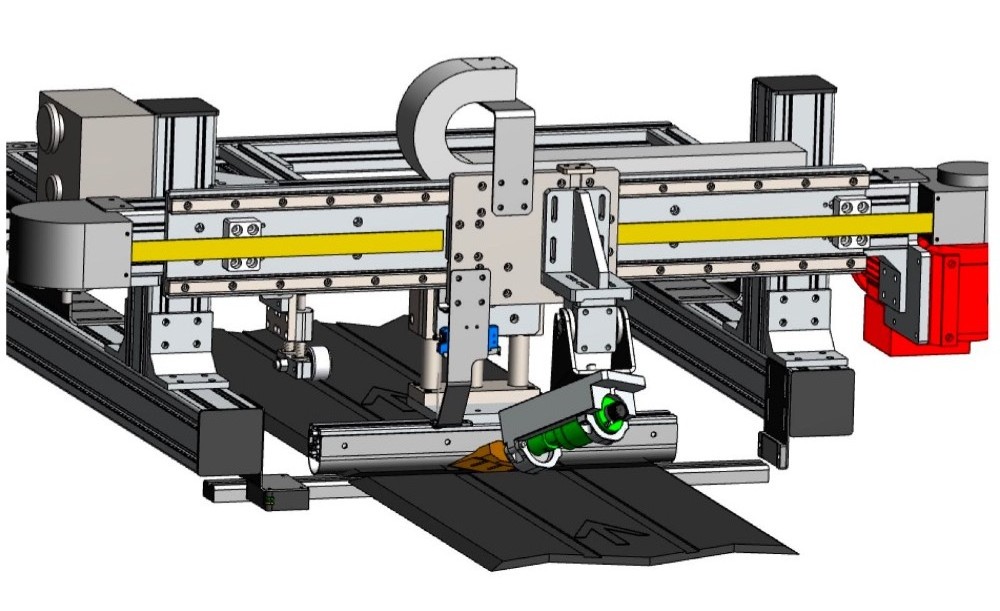

Ultrasonic rubber cutter (cutting machine) is composed of ultrasonic transducer (conveter) with cover,blade and generator. Instead of using traditional blade cutting, ultrasonic rubber cutter has its advantages of smooth, reliable cutting, accurate trimming, no deformation, no raising, fuzzing, spinning, wrinkling etc. It can avoid the rough cutting-edge, coked edge, fuzzballs and other shortcomings of laser cutting machine.

Advantages

1. High precision cutting, rubber unchanged

2. Easily applied to automated production

3. Cutting surface finish, good bonding properties

4. Speed, high efficiency, no pollution

5. Application of tire rubber parts: tread, nylon, sidewall, apex

WORKING PRINCIPLE

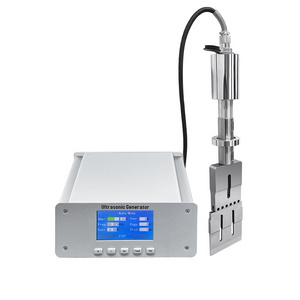

Ultrasonic cutting works by ultrasonic generator convert 50/60Hz current into 20, 30 or 40kHz power. The converted high-frequency electrical energy is converted into an equivalent frequency of mechanical vibration by the transducer , followed by a set of mechanical vibration can transmitted to the cutter device via the changed amplitude of booster. Cutter will receive the vibration energy transferred to the cutting surface of the workpiece to be cut, in the region, the vibration energy is by activating the rubber molecules, the molecular chains to open the way for cutting the plastic material.

1.Power supply

The ultrasonic power supply, also referred to as a generator, is an electronic device that takes standard 50/60Hz AC line voltage and converts it to high frequency electrical energy.

2.Converter

The ultrasonic converter is a sealed electro/mechanical device that receives the 20kHz electrical energy from the power supply and converts this electrical energy to high frequency mechanical vibrations using PZT(piezoelectric) ceramic discs that expand and contract within the converter housing.

3.Booster

The booster is a machined metal mechanical amplifier that will either raise or lower the amplitude of the horn's mechanical motion depending on the configuration of the masses machined at each end.

4.Cutting horn

The cutting horn, also referred to as a knife or a blade horn, is the component that comes into contact with the product and does the actual cutting. This horn is machined from titanium, has excellent acoustic properties, good surface hardness and superior fatigue value.

Professional ultrasonic food cutting machine

91.8% Response Rate

HI-TOO2000 compact ultrasonic cake cutting machine

91.8% Response Rate

Inline ultrasonic cake cutting machine cheese cutter

91.8% Response Rate