- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

300-320kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BOHAN

-

Dimension(L*W*H):

-

1550*550*1450mm

-

colour:

-

custom made

-

After-sales Service Provided:

-

Online Support

-

Color:

-

custom made

-

Applicable raw materials:

-

Wood, waste wood, etc.

-

Installation:

-

Engineers Guiding

-

MOQ:

-

1

-

Suitable for drying:

-

wood

-

Application:

-

coal/charcoal

-

Certification:

-

ISO CE ROHS

-

Diameter of final products:

-

30-60MM

Quick Details

-

Weight (KG):

-

1100

-

Marketing Type:

-

2024 HOT SALE

-

Warranty of core components:

-

1 years

-

Production Capacity:

-

300-320kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BOHAN

-

Dimension(L*W*H):

-

1550*550*1450mm

-

colour:

-

custom made

-

After-sales Service Provided:

-

Online Support

-

Color:

-

custom made

-

Applicable raw materials:

-

Wood, waste wood, etc.

-

Installation:

-

Engineers Guiding

-

MOQ:

-

1

-

Suitable for drying:

-

wood

-

Application:

-

coal/charcoal

-

Certification:

-

ISO CE ROHS

-

Diameter of final products:

-

30-60MM

PRODUCTS DESCRIPTION

|

power

|

output

|

weight

|

|

18.5kw

|

180-240KG/H

|

650KG

|

|

22kw-Ⅰ

|

260-300KG/H

|

800KG

|

|

22kw-Ⅱ

|

320-350KG/H

|

1000KG

|

The rod making machine, also known as the forming machine, is an indispensable equipment for the production of charcoal by the wood hair machine. It can remove granular (length≤5mm, diameter≤3mm) waste materials such as water content <12%4, water, fruit husks, straw (except rice straw and wheat straw), without any binder, after high temperature, In the high-pressure process, a solid rod with a center hole is extruded.

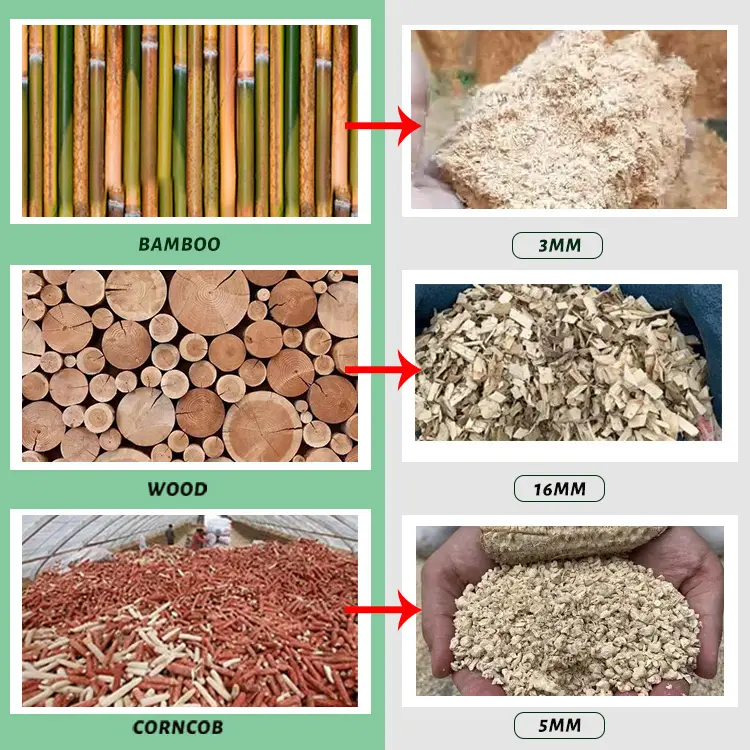

APPLICABLE MATERIALS

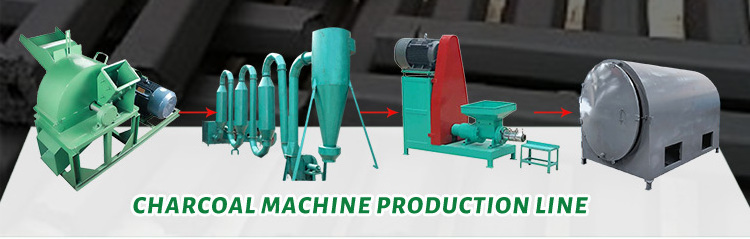

Charcoal machine is the abbreviation of several equipment: charcoal machine equipment mainly includes crusher, dryer, rod making machine and carbonization furnace. The raw materials of the charcoal machine can be sawdust, rice husk, fruit husk, rice straw, logs, branches, residues and other materials.

Main Features of the charcoal briquette making machine

1. Simple structure in linear type ,easy in installation and maintation.

2. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3. High pressure double crank to control the die opening and closing.

4. Running in a high automatization and intellectualization,no pollution

5. Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

CUSTOMIZATION PROCESS

PACKAGING AND TRANSPORTATION

ABOUT US

FAQ

Q1:

What services can be provided before the equipment leaves the factory?

A1: We will conduct a comprehensive test on the machine, and there will be obvious safety warning slogans in the position of the main parts of the machine. Such as filling hydraulic oil, equipment rotation direction, etc.

A: After the machine is loaded into the container, all accessories will be packed into a wooden box, and the installation serial number and the shipping list will be marked.

A: The photos when the machine is loaded will be sent to you. And prepare installation video and safety manual for you while the equipment is working.

Q2:How long is your delivery time?

A2:If there is stock, it usually takes 5-10 days. It takes 20-30 days to customize the equipment according to your requirements.

Q3:What if the machine is damaged?

A3:One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales service.

Hot Searches