- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Voltage:

-

380V

-

Power:

-

20KW

-

Weight (KG):

-

25000

-

Name:

-

Air Power Forging Hammer

-

Application:

-

Auto Parts

-

Usage:

-

Mental Forging Press

-

Advantage:

-

High Efficiency Metal Forging Equipment

-

Key words:

-

Open Die Header

-

Widely used:

-

Mobile Parts Forging Press

-

COLOR:

-

Costomized

-

Material:

-

Cast Iron

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

LPMIE

-

Machine Type:

-

pneumatic

-

Marketing Type:

-

Hot Product 2021

-

Voltage:

-

380V

-

Power:

-

20KW

-

Weight (KG):

-

25000

-

Name:

-

Air Power Forging Hammer

-

Application:

-

Auto Parts

-

Usage:

-

Mental Forging Press

-

Advantage:

-

High Efficiency Metal Forging Equipment

-

Key words:

-

Open Die Header

-

Widely used:

-

Mobile Parts Forging Press

-

COLOR:

-

Costomized

-

Material:

-

Cast Iron

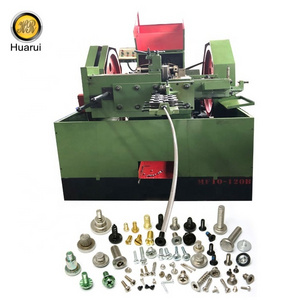

LSM11 Series Horizontal Forging Machine

Introduction:

LSM11 series horizontal forging machine, derived from German Omco technology, is currently a relatively advanced model in China. It has a wide range of applications. It is an ideal model for forging elongated special-shaped workpieces. It has multi-station forming and can be customized according to users. It is required to realize a fully automated forging process, which cannot be replaced by other equipment. There are two types of machine body structure, steel welded body and integral cast steel body. After tempering treatment, it has good rigidity and no deformation. It adopts lever principle, free transmission, low noise, high precision, convenient operation, etc.

Features:

The machine body structure is divided into two types, the steel plate welded body and the integral cast steel body. After tempering treatment, it has good rigidity and no deformation. It adopts the principle of lever, and it has free transmission and low noise. High precision, convenient operation, etc.

This equipment adopts PLC as the core control system, which has the advantages of anti-eccentric load, suitable for multi-cavity forging, fast mechanical tightening speed, reducing the contact time between the forging and the mold, thereby improving the work efficiency and extending the service life of the mold.

Application:

It can produce high-speed rail parts, reaming the end of tubing, sucker rods, making socket wrenches, automobile axle shafts, valve rods, diamond drill pipes, camshafts, square workpieces, extension bolts, etc.

Various special-shaped forgings.

The equipment adopts a block-type dry clutch, a safety double control valve, an electronically controlled automatic lubrication system, and the clamping mechanism is equipped with an overload protection device to prevent overload damage during the clamping process. The humanized equipment saves time and effort.

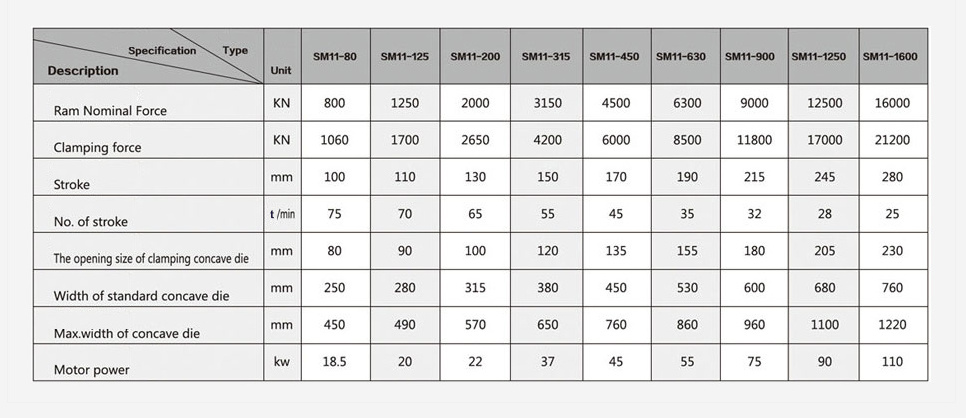

Parameters:

Workpieces:

Packing:

Whole machine and every parts wrapped by plastic film for dusting-proof.

Packed in export standard wooden case with pallet, conducive to forklift handling.

Shipping:

Shipping method: by sea, by air, by international express company.

Delivery time: 30-45 days after order confirm.

Forwarder: We have shipping forwarder agent for sending the goods to all over the world, can arrange shippment to destination port and to door for customer. We also accept forwarder agent of customer.

Why choose us?

15 years gold supplier of Alibaba.

20 years experience of machinery.

Trade assurance member of Alibaba.

How long can we get the goods?

For standard machine, we usually delivery in two weeks.

Customized machine delivery in 30-60 days.

How should I do if meet some trouble while using?

We supply 24 hours online service.

What is your terms of payment?

100% Payment before shipment or as negotiated terms with clients.

Guarantee:

12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. Out of 12 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime.

Technical support:

1, Technical support by phone, email or MSN/Skype around the clock

2, Friendly English version manual and operation video CD disk

3, Engineer available to service machinery overseas

After sales services:

Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately.

You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.