- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

380v 50hz 3phrase

-

Place of Origin:

-

China

-

Brand Name:

-

ORANGEMECH

-

Dimension(L*W*H):

-

3000*1500*2000mm

-

Weight:

-

1500 KG

-

Material:

-

Stainless Steel 304

-

Product name:

-

Liquid Filling Machine

-

Filling volume:

-

10-1000ml

-

Function:

-

Automatic Filling Capping Machine

-

Usage:

-

Liquid Filling Packaging

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Advantage:

-

20 Years Experiences

-

Air pressure:

-

0.6-0.8Mpa

Quick Details

-

Machinery Capacity:

-

500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Voltage:

-

380v 50hz 3phrase

-

Place of Origin:

-

China

-

Brand Name:

-

ORANGEMECH

-

Dimension(L*W*H):

-

3000*1500*2000mm

-

Weight:

-

1500 KG

-

Material:

-

Stainless Steel 304

-

Product name:

-

Liquid Filling Machine

-

Filling volume:

-

10-1000ml

-

Function:

-

Automatic Filling Capping Machine

-

Usage:

-

Liquid Filling Packaging

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Advantage:

-

20 Years Experiences

-

Air pressure:

-

0.6-0.8Mpa

Product Overview

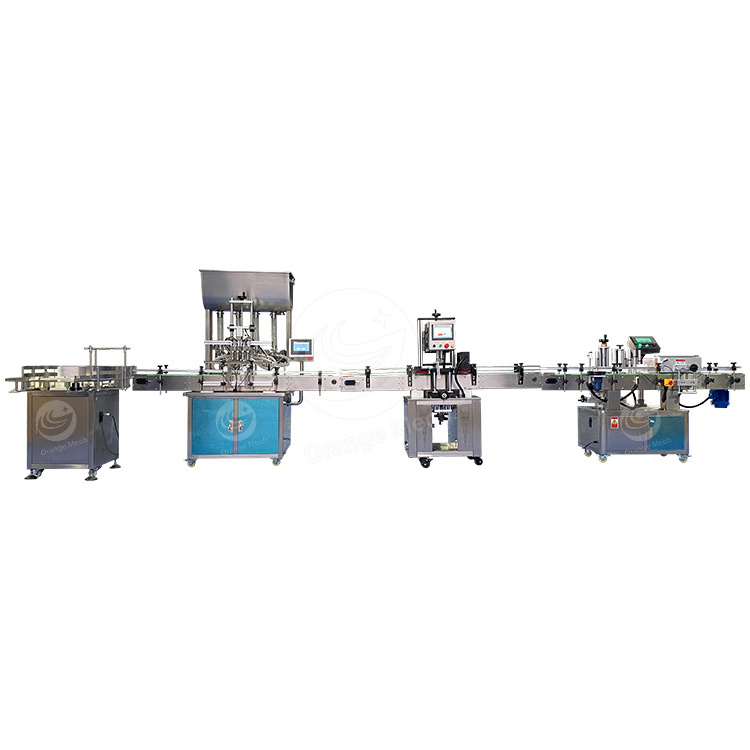

4 / 6 / 8 heads automatic liquid filling machine /filling packing machine/bottle filling capping machine Production line /

Automatic multifunctional bottle liquid filling machine with capping labeling machine(Plunger type and gear pump type)

Features:

1. This fully automatic liquid filling machine is controlled by Siemens PLC servo motor. Various filling methods such as plunger type, self-flow type and gear pump can be customized according to the type of liquid. It is easy to debug, has high filling accuracy, sensitive operation and no leakage. Easy to clean, install, etc.

2. Using advanced electrical and pneumatic components, it has stable working performance, long service time, high filling accuracy and high capping pass rate.

3. Achieve no bottle and no filling; no bottle, no capping, no leakage or water flow during the filling process. Reduce detergent raw material consumption and increase user economic benefits.

4. Users can adjust the speed and filling volume through touch screen settings. Easy to use, adjust, and maintain.

5. It can be equipped with a protective cover to prevent pollution.

6. It can work alone or be connected to a labeling machine to work together.

7. Can be equipped with wheels to facilitate moving the machine

PRODUCT SPECIFICATIONS

|

Model

|

GZJ-4

|

GZJ-6

|

GZJ-8

|

|

Capacity

|

700-1100BPH

|

8000-1500BPH

|

1000-1800BPH

|

|

Power

|

3.0KW

|

3.0kw

|

3.0kw

|

|

Weight

|

380KG

|

380kg

|

380kg

|

|

Size(L*W*H)

|

3000*1500*2000mm

|

3000*1500*2000mm

|

3000*1500*2000mm

|

|

Filling speed

|

10-70ml/s

|

10-70ml/s

|

10-70ml/s

|

|

The nozzle number

|

4

|

6

|

8

|

|

Voltage

|

110/220/380V 50/60HZ

|

110/220/380V 50/60HZ

|

110/220/380V 50/60HZ

|

PRODUCT CONFIGURATION

Related Products

Hot Searches