- Product Details

- {{item.text}}

Quick Details

-

Type:

-

graphic overlay

-

Keypad Button Material:

-

PC,PET

-

Name:

-

Dead front graphic overlay

-

Overlay material:

-

Polyester,Polycarbonate

-

Suface finish:

-

Gloss,Velvet

-

Color:

-

Pantone or RAL color

-

Buttons:

-

Flat or embossing

-

Metal dome:

-

Gold -plated metal dome,Nickel-plated metal dome

-

Printing:

-

Screen printing,Digital printing

-

Adhesive:

-

3M 467 or 468,3M 300LSE,3M VHB Foam

-

Window and Lenses:

-

Available

-

Thicknesses, sizes and shapes:

-

Customize

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

Customize

-

Type:

-

graphic overlay

-

Keypad Button Material:

-

PC,PET

-

Name:

-

Dead front graphic overlay

-

Overlay material:

-

Polyester,Polycarbonate

-

Suface finish:

-

Gloss,Velvet

-

Color:

-

Pantone or RAL color

-

Buttons:

-

Flat or embossing

-

Metal dome:

-

Gold -plated metal dome,Nickel-plated metal dome

-

Printing:

-

Screen printing,Digital printing

-

Adhesive:

-

3M 467 or 468,3M 300LSE,3M VHB Foam

-

Window and Lenses:

-

Available

-

Thicknesses, sizes and shapes:

-

Customize

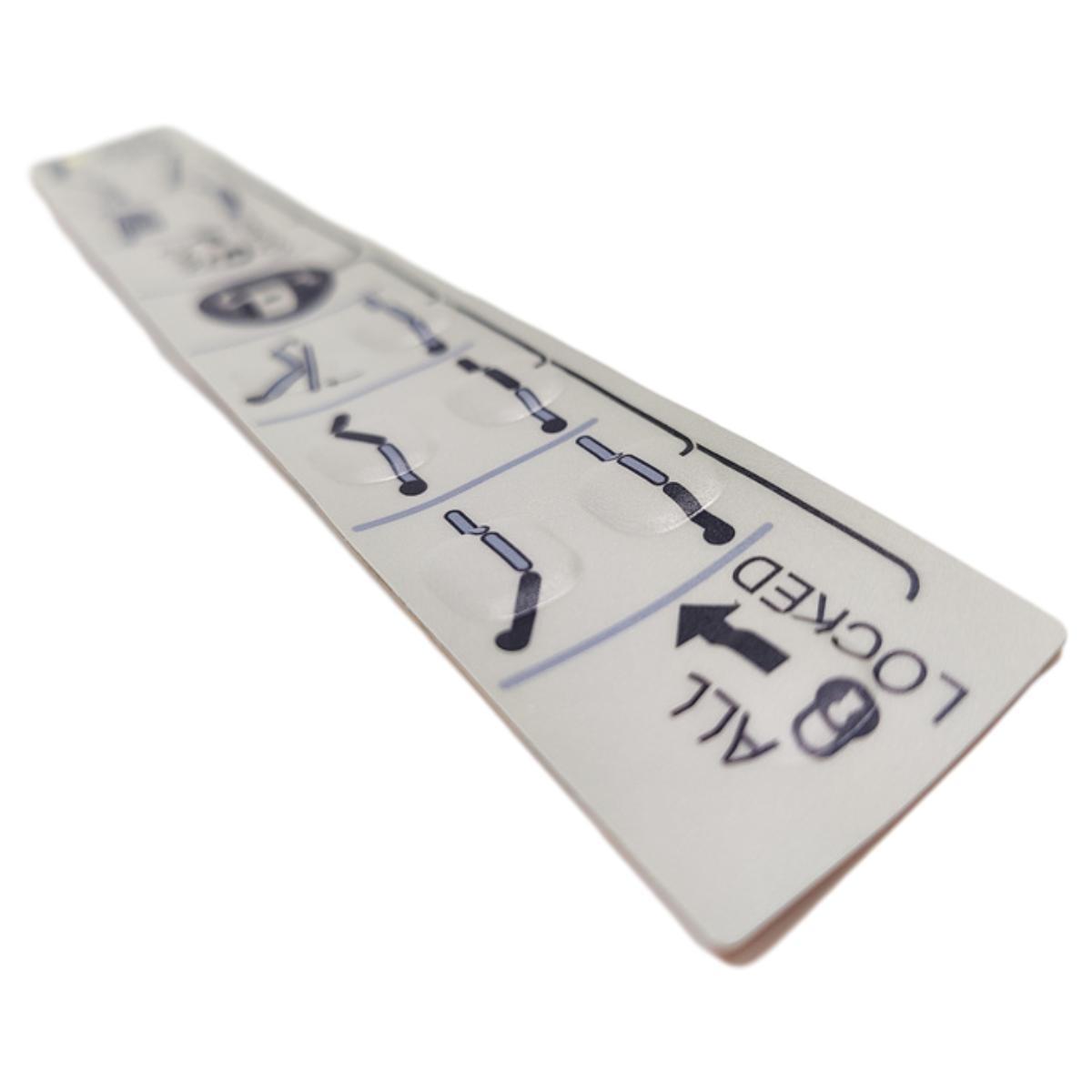

Custom manufacturing membrane panel front panel dead front graphic overlay with gold -plated metal dome for medical equipments

Dead front graphic overlay

You may be in need of dead front graphics or backlit overlays for gauges, dashboards or instrument panel overlays. These graphics will be hidden until a light source from behind reveals the icon or indicator that needs to be seen by the customer or user. Your design may also require different backlit colors for day and night. Backlit graphics can be designed to display almost any color and you will want to specify to your designer which features need to light up and the different colors for each.

Printing methods and substrates for dead front overlays

There are two ways to illuminate a dead front overlay, each of which requires a different printing approach. The first method is to use LEDs directly behind each indicator or icon. This approach simplifies the printing process (since LEDs provide the colors, the printing generally employs a single color behind each button). Alternatively, different translucent colors can be printed selectively behind various indicators. With the use of translucent colors, almost any backlighting method can be used since it’s the ink behind the iconography that gives the indicator its hue.

Diffusers are often applied behind the lights to maintain consistency throughout an overlay. Particularly with LEDs, diffusers can help eliminate hotspots, where one part of the letter or icon appears much brighter than other parts. Once a part is ready, a standard is made, so any future overlays or alterations are readily available and can easily be matched to the standard.

While dead front printing is technically possible with almost any colored bezel or overlay, it’s generally seen on overlays and bezels printed with neutral colors. Typically printed on polycarbonate, polyester, or glass, colors such as white, black, or gray tend to hide unused indicators the most effectively.

Designing your graphic overlay

| Substrates | Polyester,Polycarbonate |

| Surface Finishes | Velvet,Gloss,Anti-reflective |

| Adhesives | 3M 467 or 468,3M 300LSE,3M VHB Foam |

| Printing | Screen printing,Digital printing |

| Window and Lenses |

Clear LCD or LED

ITO using optical clear lamination Dead front Smoked as well as translucent colors for backlighting |

| In-House Embossing & Forming |

Pillow, rim, finger guide, LED, braille

Cold and hot embossing Hydroforming |

| Cutting |

Laser traced steel rule dies

Tinplate high precision tools Laser and CNC cutting |

How does custom finishes affect the design of dead front graphic overlay?

Depending on the application, custom coatings can change the front panel's visibility, feel and response speed. A matte or polished finish can change the overall look and feel of the panel, while a polished design may reduce visibility under certain lighting conditions. In addition, proper surface treatment of usable and dead front panels is essential, as the lack of proper surface treatment may result in equipment being easily soiled or scratched. Whether it's to maintain a sense of comfort or to withstand certain environmental conditions, proper surface treatment can help ensure that the product remains functional and convenient.