- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V,50HZ,3Phase, customized available

-

Dimension(L*W*H):

-

4700*3060*3030mm

-

Power (kW):

-

10

-

Weight (KG):

-

7000 kg

-

Usage:

-

Wood Plate Splicing

-

Name:

-

gluing press rotary hydraulic and clamp carrier finger joint composer

-

Working Length:

-

2700mm,4600mm,5200mm,6200mm

-

Max. Working Width:

-

1300mm

-

Working Thickness:

-

10-150mm

-

Top Cylinder Diameter:

-

80mm

-

Top Cylinder Amounts of Each Side:

-

6,8,10,12,14,16,18pcs

-

Side Cylinder Diameter:

-

40mm

-

Side Cylinder Amounts of Each Side:

-

6,8,10,12,14,16,18pcs

-

Lift Cylinder Diameter:

-

63mm

-

Lift Cylinder Amounts of Each Side:

-

2,4,6

Quick Details

-

Place of Origin:

-

China

-

Type:

-

Hydraulic Wood Press Composer

-

Brand Name:

-

ZZCHRYSO

-

Voltage:

-

380V,50HZ,3Phase, customized available

-

Dimension(L*W*H):

-

4700*3060*3030mm

-

Power (kW):

-

10

-

Weight (KG):

-

7000 kg

-

Usage:

-

Wood Plate Splicing

-

Name:

-

gluing press rotary hydraulic and clamp carrier finger joint composer

-

Working Length:

-

2700mm,4600mm,5200mm,6200mm

-

Max. Working Width:

-

1300mm

-

Working Thickness:

-

10-150mm

-

Top Cylinder Diameter:

-

80mm

-

Top Cylinder Amounts of Each Side:

-

6,8,10,12,14,16,18pcs

-

Side Cylinder Diameter:

-

40mm

-

Side Cylinder Amounts of Each Side:

-

6,8,10,12,14,16,18pcs

-

Lift Cylinder Diameter:

-

63mm

-

Lift Cylinder Amounts of Each Side:

-

2,4,6

high efficiency glulam press board making machine rotary wood composer plywood beam clamp carrier machine price

Product Description

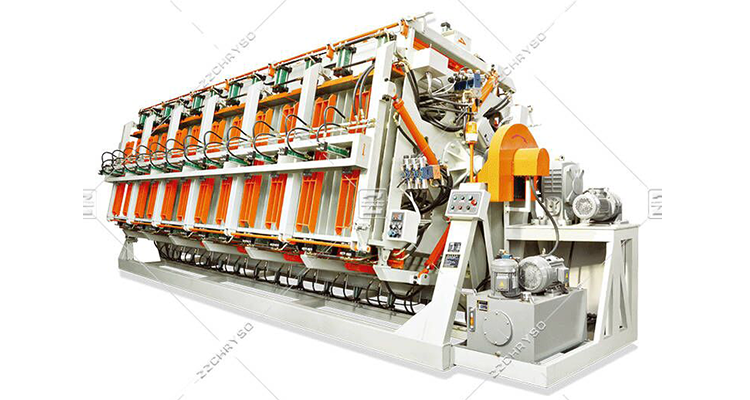

Hydraulic press machine / Rotary Clamp Carrier / Wood Board Composer

The Wood Board Composer machine adopts hydraulic principles with a stable working speed, large pressure and uniform pressing.

Rotary Clamp Carrier is used for pressing and connection for different size of board,raw material ranges from short to long width or thickness.

Wood Board Composer have several types for customers' choice: four side Rotary Clamp Carrier, double side Wood Board Composer and single side press type.

Customized specification available.

Rotary Clamp Carrier is used for pressing and connection for different size of board,raw material ranges from short to long width or thickness.

Wood Board Composer have several types for customers' choice: four side Rotary Clamp Carrier, double side Wood Board Composer and single side press type.

Customized specification available.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

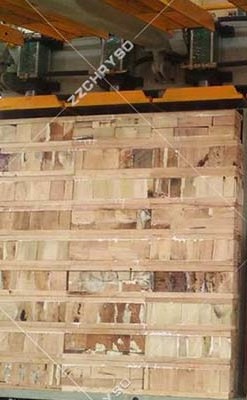

Final product of Rotary Clamp Carrier:

Compressed large size of panel, board connected with small pieces or wood.

Specification

Four side Rotary Clamp Carrier

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

1.Four side rotary hydraulic press machine(upward open type)

Simultaneous multi-layer assembly, wide processing range and high efficiency.

2.Four side rotary hydraulic Rotary Clamp Carrier (downward open type)

The downward open structure is convenient for loading and unloading of larger and longer workpieces.

The four working surfaces are cycled, four-sided imposition can be completed continuously.

The four working surfaces are cycled, four-sided imposition can be completed continuously.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

3.Four side rotary hydraulic Wood Board Composer ( Sectional type)

The segmented structure is more flexible and efficient when processing short materials.Each side can be pressed in multiple layers at the same time to improve efficiency,the processing range is wide, suitable for different processing needs.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

Technical data of Four side Rotary Clamp Carrier / Hydraulic press machine / Wood Board Composer

|

Model

|

CRS1325/4

|

CRS1346/4

|

CRS1352/4

|

CRS1362/4

|

|

Max. Working Length

|

2700mm

|

4600mm

|

5200mm

|

6200mm

|

|

Max. Working Width

|

1300mm

|

1300mm

|

1300mm

|

1300mm

|

|

Working Thickness

|

10-150mm

|

10-150mm

|

10-150mm

|

10-150mm

|

|

Top Cylinder Diameter

|

Φ80

|

Φ80

|

Φ80

|

Φ80

|

|

Top Cylinder Amounts of Each Side

|

6/8

|

10/12

|

10/12

|

12/14/16/18

|

|

Side Cylinder Diameter

|

Φ40

|

Φ40

|

Φ40

|

Φ40

|

|

Side Cylinder Amounts of Each Side

|

6/8

|

10/12

|

10/12

|

12/14/16/18

|

|

Lift Cylinder Diameter

|

Φ63

|

Φ63

|

Φ63

|

Φ63

|

|

Lift Cylinder Amounts of Each Side

|

2

|

2

|

2

|

2

|

|

Total Power

|

10kw

|

10kw

|

10kw

|

10kw

|

|

Rated Pressure of System

|

16Mpa

|

16Mpa

|

16Mpa

|

16Mpa

|

|

Overall Dimensions(L*W*H)

|

4700*3060*3030mm

|

6600*3060*3030mm

|

7200*3060*3030mm

|

8200*3060*3030mm

|

|

Weight

|

8200*3060*3030mm

|

11000-12000kg

|

11000-12000kg

|

14000-15000kg

|

Double sides rotary hydraulic Wood Board Composer

Using numerical control technology, one-button operation, according to the program settings,automatically carry out a series of actions such as pressurization, supplementary pressure, pressure maintenance, and piecing time control, so as to avoid operation differences caused by human factors and ensure the quality of assembling.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

1.Double sides rotary hydraulic Wood Board Composer (Normal type)

Apply pressure on the top and front of the workpiece to prevent back-tilt, so that the plywood can be glued to a level and perfect state. The amount of subsequent sanding is small, and the yield is high.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

2.Double sides rotary hydraulic Wood Board Composer (Sectional type)

The segmented structure is more flexible and efficient when processing short materials.

Technical data of Double sides rotary hydraulic Wood Board Composer

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

|

Model

|

CRS1325/2

|

CRS1346/2

|

CRS1352/2

|

CRS1362/2

|

|

Max. Working Length

|

2700mm

|

4600mm

|

5200mm

|

6200mm

|

|

Max. Working Width

|

1300mm

|

1300mm

|

1300mm

|

1300mm

|

|

Working Thickness

|

10-150mm

|

10-150mm

|

10-150mm

|

10-150mm

|

|

Top Cylinder Diameter

|

Φ80

|

Φ80

|

Φ80

|

Φ80

|

|

Top Cylinder Amounts of Each Side

|

6/8

|

10/12

|

10/12

|

12/14/16/18

|

|

Side Cylinder Diameter

|

Φ40

|

Φ40

|

Φ40

|

Φ40

|

|

Side Cylinder Amounts of Each Side

|

6/8

|

10/12

|

10/12

|

12/15/18

|

|

Lift Cylinder Diameter

|

Φ63

|

Φ63

|

Φ63

|

Φ63

|

|

Lift Cylinder Amounts of Each Side

|

2/4

|

2/4/6

|

2/4/6

|

2/4/6

|

|

Total Power

|

5.5kw

|

5.5kw

|

5.5kw

|

5.5kw

|

|

Rated Pressure of System

|

16Mpa

|

16Mpa

|

16Mpa

|

16Mpa

|

|

Overall Dimensions(L*W*H)

|

3100*2300*2250mm

|

5000*2300*2250mm

|

5000*2300*2250mm

|

6600*2300*2250mm

|

|

Weight

|

3000-3500kg

|

4800-5600kg

|

5500-6500kg

|

6500-8100kg

|

Details Images

Auto pressure recovery setting

Numerical control technology, one-button operation automatically pressurizes, supplements and maintains pressure according to the

program settings to ensure the quality of the final panel.

program settings to ensure the quality of the final panel.

Manual lock method

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

PLC

Single side pusher

Our Advantages

1.

High-pressure oil cylinder

—the materials and seals used are designed according to the high-pressure oil cylinder, trong pressure resistance, double seals, perfect sealing structure and longer time of sealing service;

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

2.

Digital automatic pressure compensation device

- a patented project developed by our company, the sensitivity can reach 0.1MPa, the pressure is constant, and the quality of the hydraulic press is guaranteed;

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

3. The hydraulic system is equipped with an oil return filter device to ensure clean oil and reduce failures.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

4. PLC control system , one-button operation, high degree of automation.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

3. The hydraulic system is equipped with an oil return filter device to ensure clean oil and reduce failures.

Woodworking Machinery Wood Door Composer Clamp Carrier Press Composer Machine

4. PLC control system , one-button operation, high degree of automation.

Recommend Products

Transaction record and feedback

Hot Searches