- Product Details

- {{item.text}}

Quick Details

-

Width of bed (mm):

-

500 mm

-

Spindle Motor Power(kW):

-

7.5

-

Travel (X Axis)(mm):

-

270 mm

-

Travel (Z Axis)(mm):

-

600 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2150*1750*2100

-

Brand Name:

-

Lu Young

-

Model Number:

-

AWR28

-

Voltage:

-

220V/380V

-

Weight (KG):

-

2000

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Machine Type:

-

Diamond Cutting Alloy Wheel CNC Lathe Rim Repair Machine

-

Spindle bore:

-

82mm

-

Function:

-

Machining Metal

-

Product type:

-

Economical CNC Lathe

-

Precision:

-

0.001mm

-

Name:

-

Alloy wheel repair

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

500

-

Max. Spindle Speed (r.p.m):

-

2500 r.p.m

-

Width of bed (mm):

-

500 mm

-

Spindle Motor Power(kW):

-

7.5

-

Travel (X Axis)(mm):

-

270 mm

-

Travel (Z Axis)(mm):

-

600 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2150*1750*2100

-

Brand Name:

-

Lu Young

-

Model Number:

-

AWR28

-

Voltage:

-

220V/380V

-

Weight (KG):

-

2000

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Machine Type:

-

Diamond Cutting Alloy Wheel CNC Lathe Rim Repair Machine

-

Spindle bore:

-

82mm

-

Function:

-

Machining Metal

-

Product type:

-

Economical CNC Lathe

-

Precision:

-

0.001mm

-

Name:

-

Alloy wheel repair

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

ISO9001

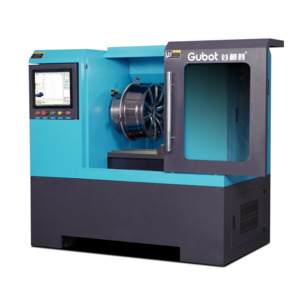

AWR28 Diamond Cutting Alloy Wheel CNC Lathe Rim Repair Machine

| Alloy wheel repair machine | AWR22 | AWR25 | AWR28 | AWR32 | |

| CNC controller | Touch Screen Operation 17" LCD Display | ||||

| Max. swig over bed Dia. | 610 | Φ635 | Φ770 (30’) | Φ880(34’) | |

| Max. Load alloy wheel Size | 22inches | 22 inches | 28 inches | 32 inches | |

| Adjustable stroke of carrier in X direction | 100mm | 100mm | 100mm | 100mm | |

| Cross slide travel (mm) | 300 | 320 | 390 | 450 | |

| Width of the rail (mm) | 260 | 300 | 330 | 400 | |

| Length of the rail (mm) | 500 | 700 | 750 | 750 | |

| Clamping type | 10’ chuck /self-centering wheel clamping | 10’ chuck /self-centering wheel clamping | 12’chuck/self-centering wheel clamping | 16’chuck/self-centering wheel clamping | |

| Probe type | Probe or laser | ||||

| Range of spindle speed (RPM) | 50~2500 | 50~2500 | 50~2000 | 50~1800 | |

| Spindle speed control | Automatic | Automatic | Automatic | Automatic | |

| Spindle bore (mm) | Φ60 | Φ60 | Φ82 | Φ82 | |

| Max. size of tool post | 25×25mm | 25×25mm | 25×25mm | 25×25mm | |

| Stations of tool carrier | 4 position | 4 position | 4 position | 4 position | |

| Min. setting unit of motor | (Z) long 0.001mm | ||||

| (X) cross 0.001mm | |||||

| Moving speed of post | (Z) long 8m/min | ||||

| (X) cross 6m/min | |||||

| Motor power | 4KW | 4kw | 5.5KW | 7.5KW | |

| Surface roughness | Ra 0.8-1.6 | ||||

| Machine size | (L×W×H) (mm³) | 1900*1400*1750 | 2100*1500*1750 | 1990 ×1600×1860 | 2470×1660×2080 |

| Package size(mm) | 2000*1400*1750 | 2200*1500*1950 | 2150×1750×2100 | 2620×1810×2300 | |

| Net weight | 1300kg | 1700kg | 2000kg | 2500kg | |

Wheel Repair Lathe Advantages

1. Cuts wheel up to 28’’.

2. With CE, SGS, ISO, BV certificates.

3. Automatic ruby laser system.

4. Easy Operation.

5. Self-developed optimization software.

6. Free Training video and manual.

7. 7x24 hours technology support.

8. 2 USB interface.

9. High efficiency and economic.

10. One-year warranty.

11. Free factory hand-to-hand training.

1

2. Agencies in UK, Germany, Poland, Netherlands, Australia etc.

flat bed rims repair wheel machine AWR28 Diamond Cutting Alloy Wheel CNC Lathe Rim Repair Machine

Cheap wheel repair CNC lathe.

Achieve the wheel surface profile measurement and data collection and Program Optimization.

Automatic precision repair and machining in accordance with the curve of the wheel surface.

Self-developed curve optimization software. Multilingual language interface. Installation and operation is simple.

Spindle frequency stepless speed.

X / Z axis servo drive.

With mandrel clamp wheel.

Automatic oil lubrication.

2. Uses

The machine tool suitable for precision turning and repair processing for surface of car wheel.

3.Technical parameters