- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1000*700*900mm

-

Weight:

-

110

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

wax candle making machine

-

Color:

-

Requairment

-

Type:

-

manual

-

Operation:

-

Easy

-

Candle Size:

-

Candle Size Selectable

-

Candle Type:

-

Straight Wax Candle

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RUIYA

-

Production Capacity:

-

224-2400pcs/h

-

Dimension(L*W*H):

-

1000*700*900mm

-

Weight:

-

110

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

wax candle making machine

-

Color:

-

Requairment

-

Type:

-

manual

-

Operation:

-

Easy

-

Candle Size:

-

Candle Size Selectable

-

Candle Type:

-

Straight Wax Candle

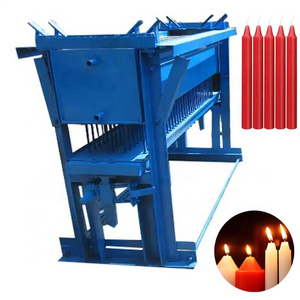

Top quality church candle making machine/candle extruder machine

Contact:Ms. Annie

Skype:ruiyamachine

Mob/Wechat/Whatsapp:0086-18037159859

Introduction of wax candle making machine:

1. Candle machine use cycle-cooling water in the whole process, so it saves water and protects environment.

2. We adopt to new material stainless steel as the mold of the candle making machine.

3.It just takes short time to cool the candles, furthermore, all the candles can be easily out of the molds at the same time.

4.We can design and manufacture candle making machines to produce different kinds of candle at customer`s request.

5.The lighting candle machine is of high productivity which is used to help candle makers save time and money

Main parameters of wax candle making machine:

|

Model |

Capacity |

|

RYC 2-1 (The machine is 2 rows 1m length) |

56pcs/time 224-336pcs/h |

|

RYC2 -1.2 (The machine is 2 rows 1.2m length) |

80pcs/time 320-480pcs/h |

|

RYC 4-1.2 (The machine is 4 rows 1.2m length) |

160pcs/time 640-960pcs/h |

|

RYC 6-1.2 (The machine is 6 rows 1.2m length) |

240pcs/time 960-1440pcs/h |

|

RYC 10-1.2 (The machine is 10 rows 1.2m length) |

400pcs/time 1600-2400pcs/h |

Our company will provide you good after services.We can help you solve the problem through video, email, phone.If needed, we can also let our engineer go to your country to solve the problem.

We hope all the customer will satisfied with our machine and services,also wish our cooperation could help you open more market and achieve win-win.

In short :

1. Accept the custom made

2. Highly pay attention to the after sell service and setting global engineer team.

3. Quality product and honest business is our principle

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to client, for your better learn about the machine's condition.

3. Delivery machine in time, taking photos during loading, so you can "remote monitoring" your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site for installation instruction.