- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

30

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.3 - 1.8 mm

-

Heating Power (kW):

-

146 kW

-

Air Comsumption(L/min):

-

3000 L/min

-

Water Comsumption(L/min):

-

11.7 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom made

-

Dimension(L*W*H):

-

L9000*W2305*H3190mm

-

Weight (T):

-

7.7 T

-

Power(KW):

-

173

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Drive System:

-

Fully automatic servo drive

-

Need to install several molds:

-

1 pairs

-

Feeding method:

-

automatic feeding

-

Forming Area:

-

750*480mm

-

Cutting method:

-

In-mold cutting

-

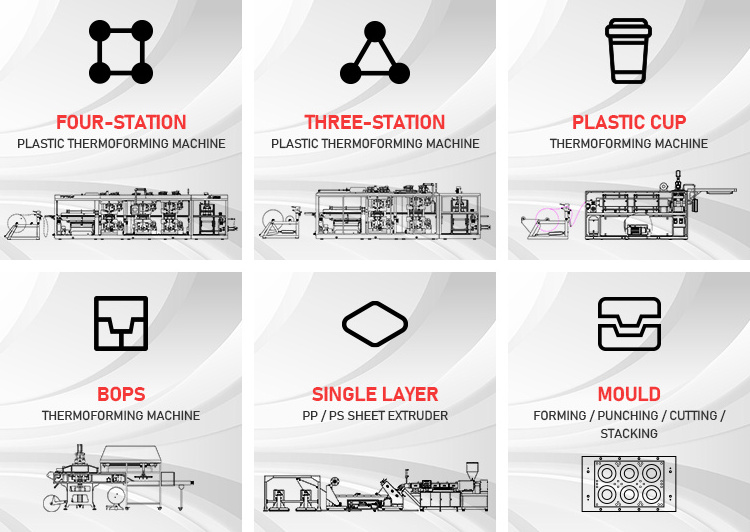

Machine type:

-

Plastic Thermoforming machine

-

Controlled:

-

Smart touch screen

-

Model:

-

4 Pillar

Quick Details

-

Max.Forming Height(mm):

-

180 mm

-

Forming Width (mm):

-

750 mm

-

Forming Length (mm):

-

480 mm

-

Production Speed(Cycles/min):

-

30

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.3 - 1.8 mm

-

Heating Power (kW):

-

146 kW

-

Air Comsumption(L/min):

-

3000 L/min

-

Water Comsumption(L/min):

-

11.7 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom made

-

Dimension(L*W*H):

-

L9000*W2305*H3190mm

-

Weight (T):

-

7.7 T

-

Power(KW):

-

173

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Drive System:

-

Fully automatic servo drive

-

Need to install several molds:

-

1 pairs

-

Feeding method:

-

automatic feeding

-

Forming Area:

-

750*480mm

-

Cutting method:

-

In-mold cutting

-

Machine type:

-

Plastic Thermoforming machine

-

Controlled:

-

Smart touch screen

-

Model:

-

4 Pillar

*Pictures and related technical parameters of products will be updated continuously without prior notice.The right of final

interpretation of this information belongs to our company.

interpretation of this information belongs to our company.

Product parameters

|

Technical Parameters

|

|

|

|

|||

|

Model

|

TQC-750S

|

TQC-750

|

TQC-650B

|

|||

|

Mould Size (Max.)

|

750*480mm

|

750*480mm

|

650*300mm

|

|||

|

Max. Forming Depth

|

180mm

|

125-180mm(custom height)

|

|

|||

|

Max. Forming Speed

|

30times/min

|

|

|

|||

|

Sheet Thickness

|

0.3-1.8mm

|

|

|

|||

|

Max.Sheet Width

|

760mm

|

|

660mm

|

|||

|

Suitable Sheet

|

PP, PS, HIPS, PET, PVC, PLA etc.

|

|

|

|||

|

Air Pressure

|

0.6-0.8mpa

|

|

|

|||

|

Air Consumption

|

3.0m³/min

|

|

2.0m³/min

|

|||

|

Water Consumption

|

0.7m³/h

|

|

0.5m³/h

|

|||

|

Rated Power

|

173Kw

|

|

98Kw

|

|||

|

Heating Power

|

146Kw

|

|

78Kw

|

|||

|

Used Power

|

121Kw

|

|

68Kw

|

|||

|

Power Supply

|

AC 380V,50Hz, Three-phase, Four-wire

|

|

|

|||

|

Dimension

|

L9000*W2305*H3190mm

|

L8500*W2200*H3200mm

|

L7000*W2000*H3100mm

|

|||

|

Weight

|

About 7.7T

|

About 6.5T

|

About 5T

|

|||

|

MACHINE MAIN PARTS

|

|

|

|

Touch Screen/PLC

|

SIEMENS (Germany)

|

|

|

Servo Motor

|

INOVANCE (China)

|

|

|

Motor

|

JSCC (China)

|

|

|

Frequency Changer

|

INOVANCE (China)

|

|

|

Air Switch/Contactor/Circuit Breaker

|

SCHNEIDER (France)

|

|

|

Proximity Switch

|

ROCKWELL (America)

|

|

|

Solid State Relay

|

FOTEK (Taiwan)

|

|

|

Oil Pump

|

SCENERY (JointVenture)

|

|

|

Forming Valve

|

SMC (Japan)

|

|

|

Solenoid Valve

|

MINDMAN(Taiwan)

|

|

|

Cylinder

|

KAOGEER(China)

|

|

|

Heater

|

TIANBAO(China)

|

|

Products Description

APPLICATION

About our TQC series plastic cup theremforming machine have 5 big advantages, let me truduce it one by one for you. First, more powerful , our configuration support by the powerful brand, such as Yaskawa, siemens, schnieder thoses kinds of famous brand. With thoses brands our machine refects stable and high quality. Secondly, more efficience, the double oven is almost 7 times the index length of the forming area so it brings the production with high effience, also in making PP material the speed can be also over 25 times/min. Third, flexible and varity options, the forming deepth, forming area, hearting tile brand can meet the requirement of different output, different products. Fourth, more stable, the four pilar and lubrication by a certain amount time not only bring super stablity on machine struction, but also make a geat contrubution on the stablity machine works. Last but not least is -atomatically, our machine is easy for handing, production in auotmatcially, so it can reduce worker resoures.

SUMMARY OF MACHINE

Fully automatic feed rack

1. Load automatically, lower human resource cost.

2. Sheet conveying positively, lower the load of conveying servo motor.

3. Proximity Switch clever control, getting the rid of falling down of the sheet by conveying too fast.

4. Double stations, big diameter, reduce the frequency of changing sheet coil, improve the the production efficiency.

5. Sheet feeder with a swing rod, good look and clever control.

Heating part

1. Adopt Chinese top brand Tianbao heating tile, excellent insulation performance and heating efficiency, which results in saving time and energy. . Based on this, the actual power consumption is about 60% of the rated power, it's awesome and amazing.

2. The stove has almost 7 times the width of the forming area, so that the sheet can go through a longer distance in a certain plasticizing time, to improve the speed so that to improve the output.

3. Divided by two layers of the stove with optimized heating tile layout, makes the sheet heated fully and evenly.

4. The whole stove is divided into multi separate temperature control units, the accuracy is controllable at 1 degree Cels to ensure that the sheet of each product is perfectly plasticized.

Four pillars

Four pillars can ensure the machine stability and lower the noise in the process of machine operation.

Forming system

1. Adopt the structure of four-pillars(40Cr steel) for supporting and uni-body mould plates (TQ-600 steel) for guiding, which make our forming station more stronger and stable, shock absorption and wear resisting.

2. The forming part is driven by servo motor system, super power which is reliable and steady. Using proximity switch to control the precision of the excellent mould positioning.

3. The parallelism misalignment between guide plate is less than 0.05mm, and for mould, less than 0.03mm, much lower than the industry average value. so our forming product size will be more precision, bottom will be more perfect.

4. The fixed upper and lower guide plates, as well as the excellent parallel and flexible middle guide plates, have high material hardness, good wear resistance and strong corrosion resistance, ensuring the smooth operation and durability of the machine.

5. The hydraulic drive structure of cross-link adopts wear resisting steel bushing, bears more weight, rotates more precise. And the symmetrical swing ensures the parallelism of machine running, to avoid four pillars transverse abrasion, and make the machine more long-life.

6. Integrated hydraulic station with buffer function, high power, enough force, small vibration, good control , super stability and easy maintenance.

7. The intelligent lubrication system can lubricate by a certain amount and time, which can make the machine longevity and sustainability.

8. The mould cavity has the cooling water inside, which expedites the cooling speed and the bottom is equipped an ejector rod which makes the products easy to demould.

9. The working theory is a combination of positive pressure with assisting stretching in mould by some nylon plugs, which makes it have more powerful ability of making products.

10. Stretching by servo motor , super precision, high efficiency.

11.Individually replaceable blades with high-quality material that are affordable, flexible, and durable.

Stacking

Basically, there are three methods for stacking finished products. The first one is collected by manually, the second is by belt stacker as the video shows, this is most suitable for collecting cups, the third is by robot stacker, this is most suitable for collecting trays, plates, food containers and small cups.

Robot stacking

After the cup is formed in the molding mold, the cup is grabbed out of the molding mold by a suction manipulator, and then the cup is placed into the stacking mold. The advantage is that the cups are stacked neatly, reducing labor and saving labor costs.

Stacking molds

The robot grabs the cups and puts them into the stacking mold, stacking them neatly

Stacking molds

The robot grabs the cups and puts them into the stacking mold, stacking them neatly

Product line conveyor belt

The cup push structure pushes each column of cups into the product conveyor belt and arranges them neatly

Sealing

Each row of cups is arranged on the product line conveyor belt, and the cups are pushed into the single-track sealing and packaging line for packaging by rotating the conveyor belt.

Online crusher

The formed scrap sheet roll will be crushed in the online crusher through the winding frame for recycling and reuse through the sheet extruder.

Hot Searches