- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CapsulCN

-

Weight (KG):

-

1500

-

Product name:

-

Capsule Counting Machine line

-

Application:

-

Tablet Capsule Pill Candy Counting

-

Function:

-

Tablet Pills Counting

-

Keyword:

-

Counting Bottling Machine

-

Feature:

-

High Precision

-

Voltage:

-

Customer

-

Counting:

-

Tablet Capsule Soft Gel

-

Material:

-

Staninless Steel

Quick Details

-

Capacity (pcs/h):

-

230000 pcs/h

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CapsulCN

-

Weight (KG):

-

1500

-

Product name:

-

Capsule Counting Machine line

-

Application:

-

Tablet Capsule Pill Candy Counting

-

Function:

-

Tablet Pills Counting

-

Keyword:

-

Counting Bottling Machine

-

Feature:

-

High Precision

-

Voltage:

-

Customer

-

Counting:

-

Tablet Capsule Soft Gel

-

Material:

-

Staninless Steel

Products Description

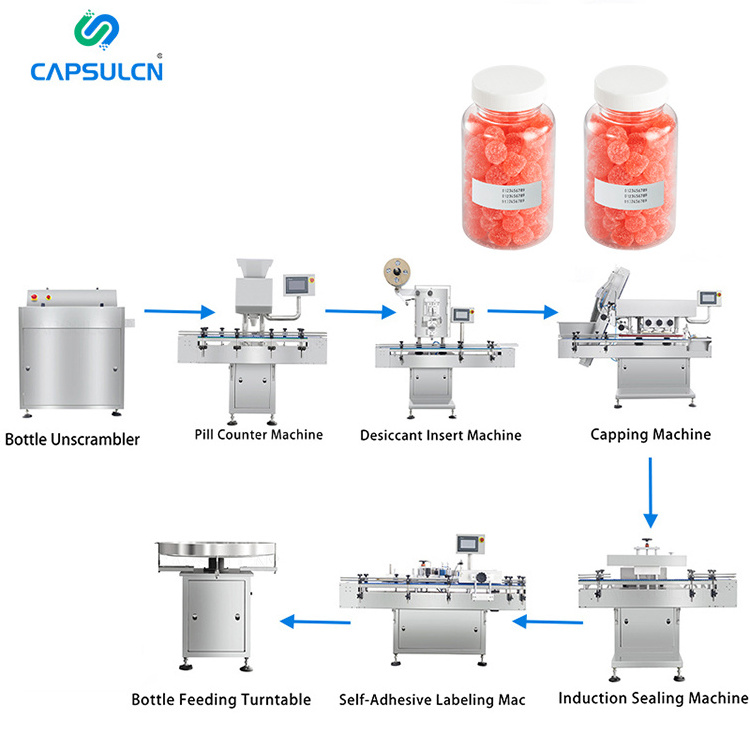

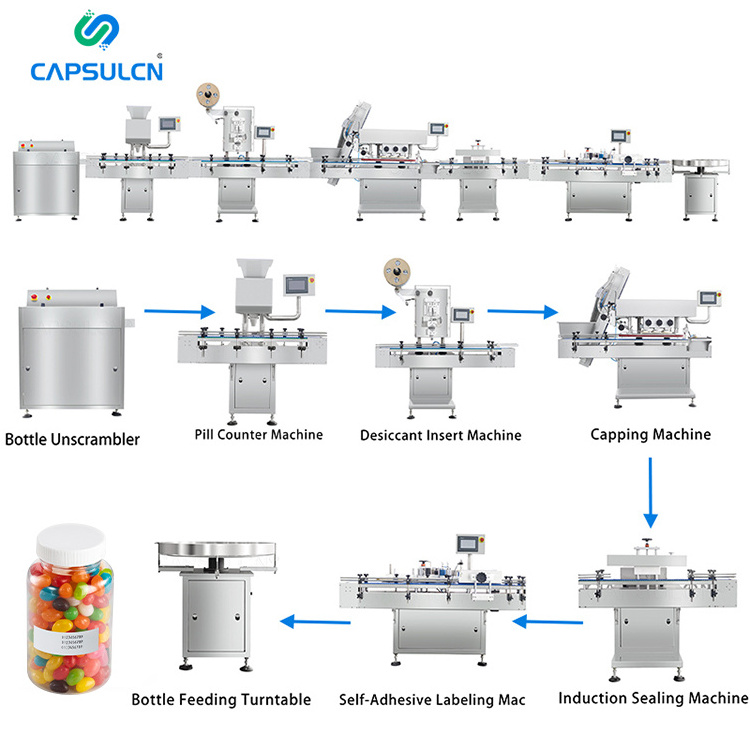

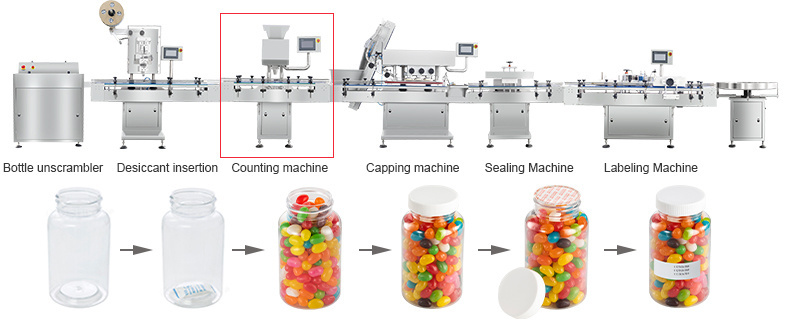

Automatic Capsule & Tablet Counting Machine

This complete automatic bottling line conforms to GMP standard. On the basis of practicability and efficiency, it can help you save cost and complete the bottling and packaging of products more accurately and beautifully. As you can see, it is of a high degree of automation, stable and reliable product performance, convenient operation and maintenance, exquisite and beautiful appearance. What’s more, it can ensure that every product under the production line is flawless. All you have to do is watching it produce!

Cost saving

:

Eleven machines in one line take the place of eleven labours, which greatly helps reduce cost.

More practical : Compared with manual labeling, labeling bottles by the labeling machine can make the product more beautiful and firmer.

Multiple-choice : Each machine on the production line can be matched at will, and other equipment can be added at any time in the future.

High precision : The design of three-stage vibration can help avoid stacking, ensuring the accuracy and count error is lower than 1/10000.

More practical : Compared with manual labeling, labeling bottles by the labeling machine can make the product more beautiful and firmer.

Multiple-choice : Each machine on the production line can be matched at will, and other equipment can be added at any time in the future.

High precision : The design of three-stage vibration can help avoid stacking, ensuring the accuracy and count error is lower than 1/10000.

Details Images

|

1、High-Speed Automatic Bottle Unscrambler

|

|

|

|

Model

|

CED-80LP

|

|

|

Bottle specification (ML)

|

50~300

|

|

|

Max. production capacity (Bottle/Min)

|

60~100

|

|

|

Power (kW)

|

0.5

|

|

|

Voltage (V)

|

220

|

|

|

Overall dimension (L*W*H) (mm)

|

2200*1050*1900

|

|

|

Weight (kg)

|

250

|

|

|

|

||

Used in many different shapes and specifications of plastic bottles in companies to automatically arrange andoutput directionally. It is an ideal supporting equipment for various plastic bottle production lines.

|

2、Automatic Capsule Tablet Counting Machine

|

|

|

|

Model

|

CED-8

|

|

|

Rate of production

|

10~30 bottles/min

|

|

|

Single bottling capacity

|

2-9999 pcs/bottle

|

|

|

Common type

|

Pills, tablets, soft and hard capsules and other solid tablets

|

|

|

Bottle diameter

|

φ20~φ100mm

|

|

|

Bottle height

|

40~240mm

|

|

|

|

||

This machine can be widely used for fast counting and bottling of various shapes and sizes of tablets, capsules, pills and other food, health care products and other materials. The counting and bottling speed and accuracy rate have reached the advanced level of similar products at home and abroad.

|

3、Automatic Desiccant Inserting Machine

|

|

|

|

Model

|

CED-GS

|

|

|

Filling speed of desiccant sachets

|

50~120 bottles/min

|

|

|

Bottle’s outer diameter

|

Φ20~80 mm

|

|

|

Bottle’s height

|

35~200 mm

|

|

|

Applicable range of desiccant sachets

|

0.5~2 g

|

|

|

Voltage

|

220V 50Hz

|

|

|

Overall dimension (L*W*H)

|

1150*800*1900 mm

|

|

|

Weight

|

300 kg

|

|

|

|

||

This machine is an upgraded product of our company. It has simple structure and easy operation. More importantly, stepless adjustment can be made to the production capacity according to the specifications and characteristics of bottles and desiccant sachets. This machine has strong adaptability to bottles. For glass bottles and plastic bottles of various specifications containing food, cosmetics, the filling effect of desiccant sachets is satisfactory.

|

4、High-Speed Capping Machine

|

|

|

|

Model

|

CED-CG

|

|

|

Max. production capacity

|

50~120 bottles/min

|

|

|

Bottle’s outer diameter

|

Φ23~120 mm

|

|

|

Bottle’s height

|

45~150 mm

|

|

|

Bottle cap’s outer diameter

|

Φ20~120 mm

|

|

|

Overall dimension(L*W*H)

|

2200*1050*1900mm

|

|

|

Weight

|

650 KG

|

|

|

|

||

CED-CG series can complete the process of automatic bottle feeding, cap unscrambling, cap conveying, cap putting, cap pressing, cap screwing and bottle discharging.

|

5、Induction Aluminum Foil Sealing Machine

|

|

|

|

Model

|

CED-LF

|

|

|

Sealing speed

|

120~200 bottles/min

|

|

|

Sealing diameter of heating head

|

ø20mm~ø60mm

|

|

|

Input current

|

≤3.5A (when no bottles pass)

|

|

|

|

≤10A (when bottles pass)

|

|

|

Output power

|

Max. 2 kW (adjustable)

|

|

|

Output waveform

|

60~80KHz (Sine wave)

|

|

|

|

||

Composite electromagnetic induction sealing technology is an internationally recognized advanced sealing packaging method. It has been increasingly widely used in high-quality air-tight sealing of food, cosmetics, pesticides, chemical products and other bottled products.

|

6、Self-Adhesive Labeling Machine

|

|

|

|

Model

|

CED-TB100

|

|

|

Labeling speed

|

20~120 bottles/min

|

|

|

Bottle’s outer diameter

|

Φ20~80 mm

|

|

|

Bottle’s height

|

35~200 mm

|

|

|

Applicable label length

|

23~250 mm

|

|

|

Applicable label height

|

15~125 mm

|

|

|

Overall dimension

|

2000mm*700mm*1650mm

|

|

|

Weight

|

280 kg

|

|

|

|

||

Self-adhesive Labeling Machine for Round Bottles is an upgraded product of our company. It has simple structure and easy operation. Stepless adjustment can be made to the production capacity according to the specifications and characteristics of bottles and label paper.

|

7、Bottle Feeding Machine/Bottle Collecting Machine

|

|

|

|

Model

|

CED-200

|

|

|

Production capacity

|

30~200 bottles/min

|

|

|

Bottle diameter

|

20-80mm

|

|

|

Range of application

|

Round bottles, square bottles, flat square bottles, special-shaped bottles, etc. of various materials

|

|

|

Dimensions

|

900×900×1000mm

|

|

|

Weight

|

95kg

|

|

|

View Details>>

|

|

|

Automatic Rotary Bottle Conveyor is suitable for cosmetic, food and other industries. It can convey glass bottles, plastic bottles, round bottles and square bottles. The product can convey bottles in order to the next working procedure, making it more efficiently to arrange bottles.

|

8、Automatic Horizontal Cartoning Machine

|

|

|

|

Model

|

DZH-120

|

|

|

Cartoning speed

|

30-120 cartons/min

|

|

|

Carton quality requirements

|

300-350g/m²

|

|

|

Dimension range of carton(mm)

|

(60-200)×(25-85)×(15-65)

|

|

|

Air consumption

|

15-20m³/h

|

|

|

Dimensions(mm)

|

3150×1180×1950

|

|

|

Net weight of machine

|

about 1500kg

|

|

|

|

||

Horizontal Cartoning Machine is a new product developed by our company, which is a multi-functional cartoning machine integrated with machine, electricity and gas. It has the advantages of small size, light weight, wide application range, high production efficiency, and can be used for multiple purposes in one machine.

|

Transparent Film Packaging Machine

|

|

|

|

Model

|

BT-2000B

|

|

|

Production Capacity

|

40-60 packs/min

|

|

|

Packaging Size Ranga(mm)

|

(L)40-160(W)20-100 (H)10-50

|

|

|

Power Supply

|

220V 50-60Hz

|

|

|

Motor Power

|

0.75kW

|

|

|

Electric Heating

|

3.7kW

|

|

|

Dimensions(L×W×H)

|

2400mm×800mm×1560mm

|

|

|

Total Weight

|

880kg

|

|

|

|

||

This versatile machine is designed for three-dimensional packaging of various types of cardboard boxes by using environmentally friendly OPP or BOPP film. It’s capable of packaging a wide variety of sizes and applications from food, cosmetics, tea, nutraceuticals, cigarettes, and playing cards to DVDs.

Why Choose Us

Pre-sale service

1.

Support product customization

, any requirements you need can be customized according to your requirements.

2. Sample test on our machine.

3. Provide business consulting and technical support, as well as a free professional packaging solution.

4. Make a machine layout for customers based on customers' factories.

After-sales service

1. Manual book.

2. Videos of installation, adjusting, setting, and maintenance, are available for you.

3. Online support, or face-to-face online communications, are available.

4.

The engineer overseas services

, are available. The tickets, visa, traffic, living, and eating, are for customers.

5. During the warranty year, without human-being broken, we will replace a new one for you.

Hot Searches