- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

500 mm

-

Dimension(L*W*H):

-

Table size 1000x500mm

-

Weight (T):

-

5 T

-

Table Travel (Z) (mm):

-

500 mm

-

Positioning Accuracy (mm):

-

0.001

-

Repeatability (X/Y/Z) (mm):

-

0.008

-

Range of Spindle Speed(r.p.m):

-

10 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5

-

Max. Table Load(kg):

-

500 kg

-

Feed Speed(mm/min):

-

10 - 10000 mm/min

-

Rapid Feed Speed(m/min):

-

20mm/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Alles CNC

-

Voltage:

-

Customer's Requirement

-

Marketing Type:

-

Hot Product

-

Worktable size:

-

1000x500mm

-

Worktable Max. load:

-

400kg

-

Travel X axis travel:

-

800mm

-

Travel Y axis travel:

-

500mm

-

Travel Z axis travel:

-

500mm

-

Spindle speed:

-

10000rpm

-

Spindle taper:

-

BT40

Quick Details

-

Table Size (mm):

-

1000x500

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

1000 mm

-

Table Travel (Y) (mm):

-

500 mm

-

Dimension(L*W*H):

-

Table size 1000x500mm

-

Weight (T):

-

5 T

-

Table Travel (Z) (mm):

-

500 mm

-

Positioning Accuracy (mm):

-

0.001

-

Repeatability (X/Y/Z) (mm):

-

0.008

-

Range of Spindle Speed(r.p.m):

-

10 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5

-

Max. Table Load(kg):

-

500 kg

-

Feed Speed(mm/min):

-

10 - 10000 mm/min

-

Rapid Feed Speed(m/min):

-

20mm/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Alles CNC

-

Voltage:

-

Customer's Requirement

-

Marketing Type:

-

Hot Product

-

Worktable size:

-

1000x500mm

-

Worktable Max. load:

-

400kg

-

Travel X axis travel:

-

800mm

-

Travel Y axis travel:

-

500mm

-

Travel Z axis travel:

-

500mm

-

Spindle speed:

-

10000rpm

-

Spindle taper:

-

BT40

Products Description

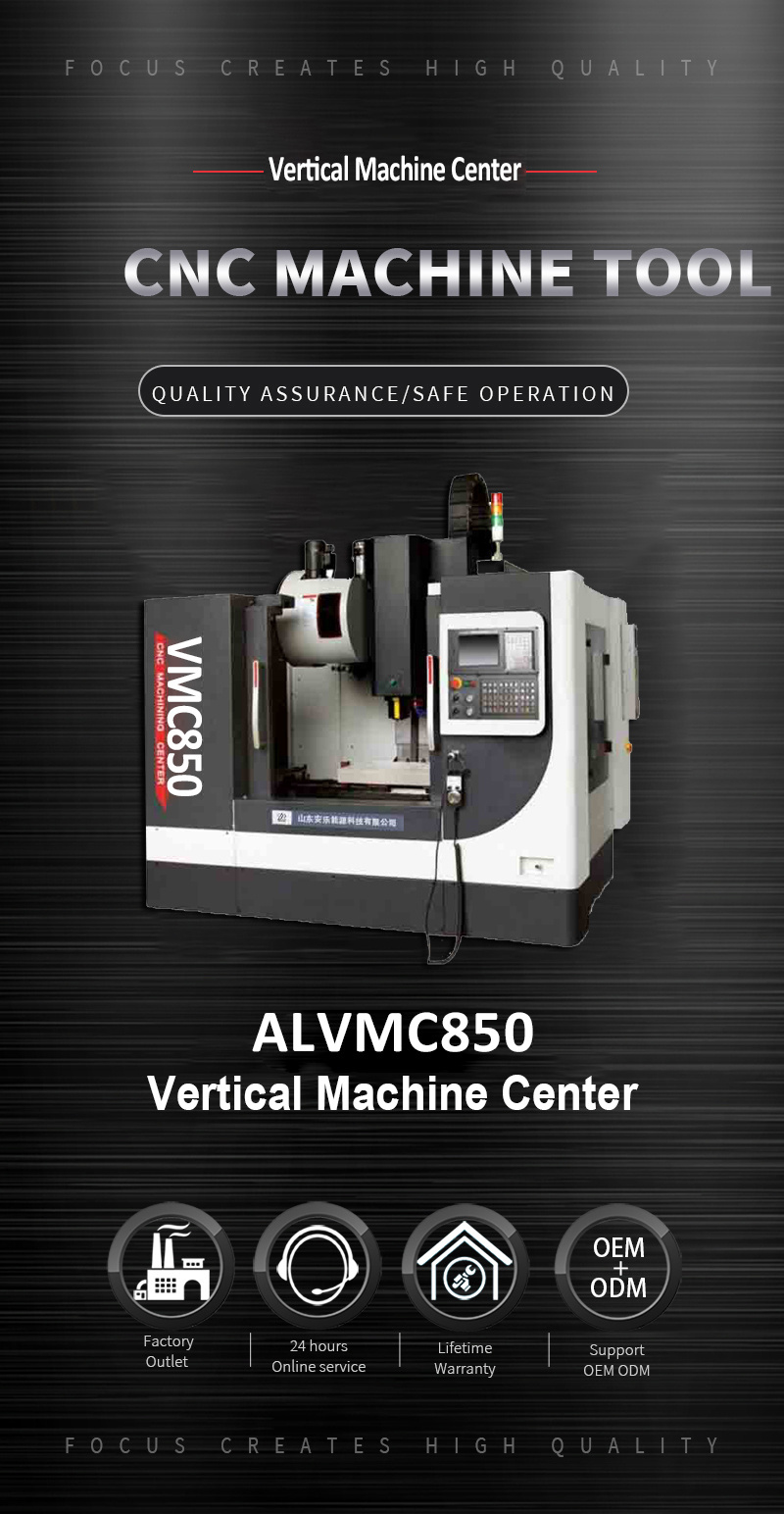

ALVMC850 Vertcal Machine Center I ntroduce:

This

ALVMC650 vertcal machine center

is suitable for the mechanical processing and mold making. And it can adapt to the processing requirement from rough machining to finish machining. It can also finish many working procedures like milling, drilling, tapping, boring etc.

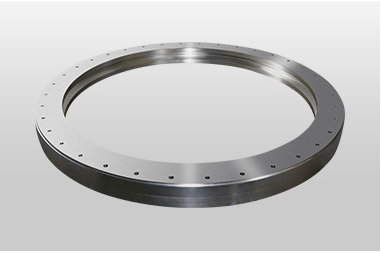

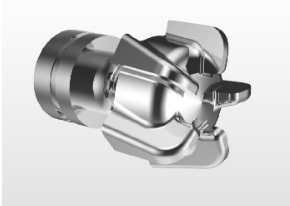

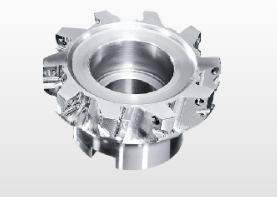

Workpiece display

The VMC650 vertical machining center consists of main engine, CNC system, electrical control system, automatic lubricating system, cooling system, totally enclosed protective cover, automatic chip removal device (optional) etc.The machine has the X, Y, Z three axis linkage, in a clamping can finish milling, drilling, boring, expanding continuously, hinge, such as the internal and external screw thread processing a variety of rough and finish machining process, is suitable for processing all kinds of high precision, working procedure, shape more complex parts, to provide users with complex parts processing and quick, perfect integration solutions.

Product Paramenters

|

Specifications

|

Unit

|

ALVMC650

|

ALVMC850

|

|

Table maximum load

|

kg

|

450

|

600

|

|

X/Y/Z axis travel

|

mm

|

650x400x500

|

800×500×600

|

|

Distance between spindle center and column guide surface

|

mm

|

476

|

560 ( 579)

|

|

Distance between spindle end face and worktable surface

|

mm

|

100-600

|

140-740

|

|

X/Y/Z Max. feed speed

|

mm/min

|

10000

|

10000

|

|

X/Y/Z Max. Rapid traverse

|

m/min

|

24/24/20

|

20/20/15

|

|

The spindle maximum speed

|

r/min

|

8000

|

8000

|

|

Repeat positioning accuracy

|

mm

|

±0.004

|

±0.004

|

|

Machine size (L×W×H)

|

mm

|

2300×2200×2400

|

2700×2400×2700

|

|

Net. weight (about)

|

kg

|

4500

|

5700

|

Quality Inspection

Machine details

Customer Photos

Product packaging

FAQ

1: What's your main products of your company?

A : We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

2:What kind of controlsdo you use on machines?

A :Siemens,GSK ,Fanuc etc. You can choose according to your requirements .

3. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

4 : How can I choose the most suitable machines ?

A : Please tell me the model or parameter you are interested in, we can provide you with the best price and quality.

You can also send us product pictures and we will choose the most suitable machine for you.

5 : Do we receive any updates while machine is in the manufacturing process?

A : Of course. The progress of the machine will be updated regularly and sent to you.

Hot Searches