- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

QJ

-

Voltage:

-

380V

-

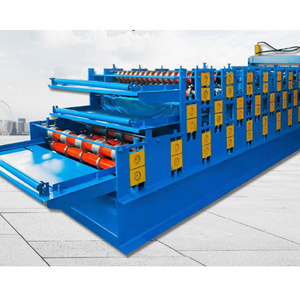

Dimension(L*W*H):

-

8.7m*1.3m*1.3m

-

Weight:

-

4.5T

-

Thickness:

-

0.3mm~0.8mm

-

Motor Power:

-

5.5KW with Cycloidal reducer

-

Cutting Mold:

-

Cr12 mould die

-

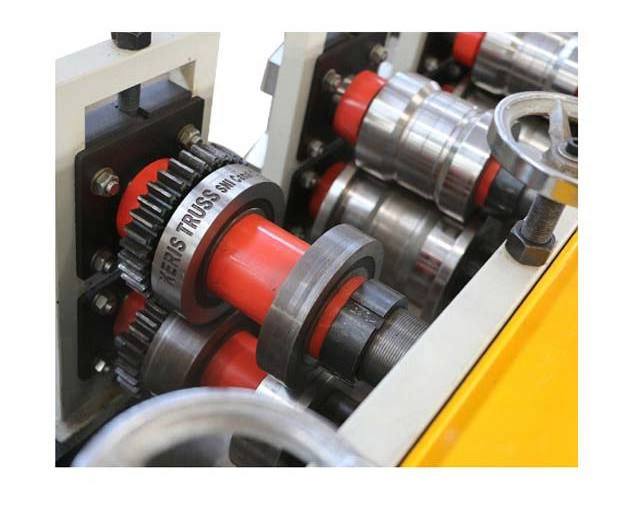

Roller:

-

18 rows

-

Shaft Diameter:

-

70mm

-

Shaft Material:

-

45# Steel

-

Certification:

-

TUV SGS

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

12m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

QJ

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8.7m*1.3m*1.3m

-

Weight:

-

4.5T

-

Thickness:

-

0.3mm~0.8mm

-

Motor Power:

-

5.5KW with Cycloidal reducer

-

Cutting Mold:

-

Cr12 mould die

-

Roller:

-

18 rows

-

Shaft Diameter:

-

70mm

-

Shaft Material:

-

45# Steel

-

Certification:

-

TUV SGS

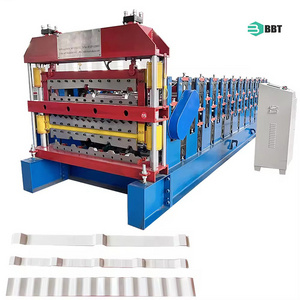

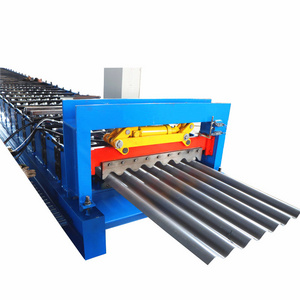

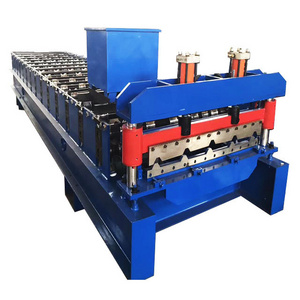

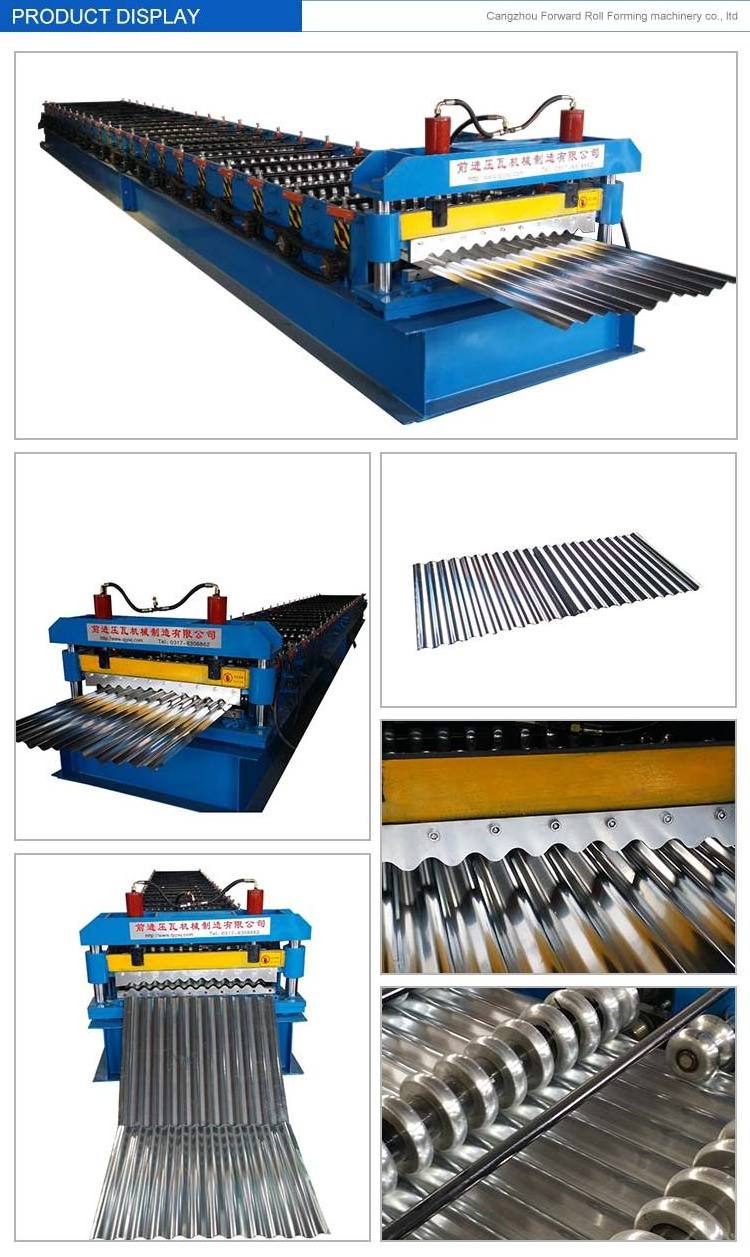

new type prepainted aluzinc hot dip galvanized steel glazed roof tile roll forming machinery

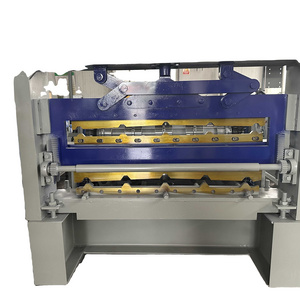

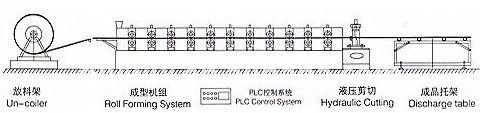

Process flow

Decoiling-active feeding-roll forming-measuring length-cutting to length-product to stand

Technical Parameter

|

Suitable material |

Color steel sheet , galvanized steel sheet |

|

Main motor power |

5.5KW with Cycloidal reducer |

|

Hydraulic station power |

3KW |

|

Hydraulic oil |

36# |

|

Thickness of material |

0.3mm~0.8mm. |

|

Diameter of principal axis |

Φ75mm |

|

Material expand width |

1050mm |

| Voltage Standard |

380V 3phase 50HZ (For confirmation) |

|

Roller Material |

High grade 45# forged steel |

|

Galvanization thickness |

0.05mm |

|

Rolling speed |

8-12m/min |

|

Length Tolorance |

1.00mm |

|

Cutting Die |

Cr12 mould steel |

|

Transmission Method |

1 inch chain link bearing model 6210 |

|

Roller Stations |

18 Steps |

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2.Transportation : Machines need one 40 feet container to hold.

Q 1 . What are the main key points for selecting right machines ?

A 1 : Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.

Good quality is for long-term business cooperation.

Q 2 . Can you provide OEM service for roll forming machine ?

A 2 : Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q 3 . What ’ s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q 4 . How about the quality control ?

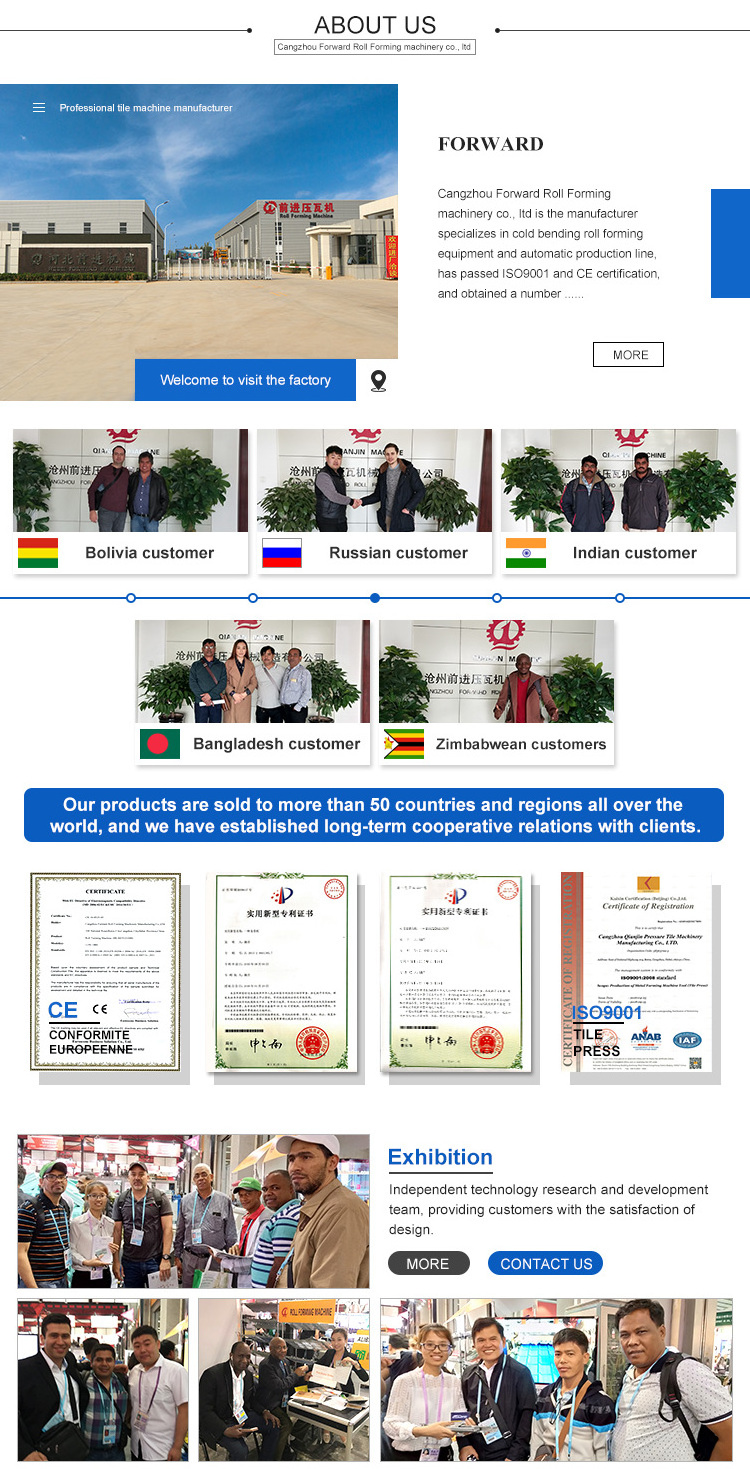

A 4 : Our c o mpany adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV() Certificate.

Q 5 . How about the after-sale service ?

A 5 : We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freel y.

Q6. If I am in Beijing ,Shanghai or Guangzhou ,h ow to visit your company?

A6: 1) Beiing South Statioin to Cangzhou West Station ( by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

When you arrive our station, we will arrange to pick up you there!