- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SHM

-

Voltage:

-

380V

-

Power:

-

20-35KW

-

Weight:

-

6000 kg

-

Raw material:

-

Waste Recycled Paper or Plant fiber

-

Application:

-

Packing Industry

-

Keyword:

-

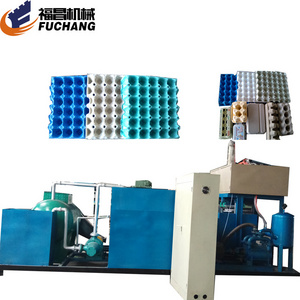

Fruit Tray Making Machine Disposable

-

Finished Products:

-

Fruit Tray

-

Machine type:

-

Automatic Paper Pulp Fruit Tray Machine

-

Machine for:

-

Pulp Molding Processing

-

Advantage:

-

Plastic free

-

Product name:

-

Fruit tray container making machine

-

Certification:

-

CE, ISO9001

-

Name:

-

Apple tray making machine

Quick Details

-

Production Capacity:

-

500pcs/h

-

Product Type:

-

Fruit

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

SHM

-

Voltage:

-

380V

-

Power:

-

20-35KW

-

Weight:

-

6000 kg

-

Raw material:

-

Waste Recycled Paper or Plant fiber

-

Application:

-

Packing Industry

-

Keyword:

-

Fruit Tray Making Machine Disposable

-

Finished Products:

-

Fruit Tray

-

Machine type:

-

Automatic Paper Pulp Fruit Tray Machine

-

Machine for:

-

Pulp Molding Processing

-

Advantage:

-

Plastic free

-

Product name:

-

Fruit tray container making machine

-

Certification:

-

CE, ISO9001

-

Name:

-

Apple tray making machine

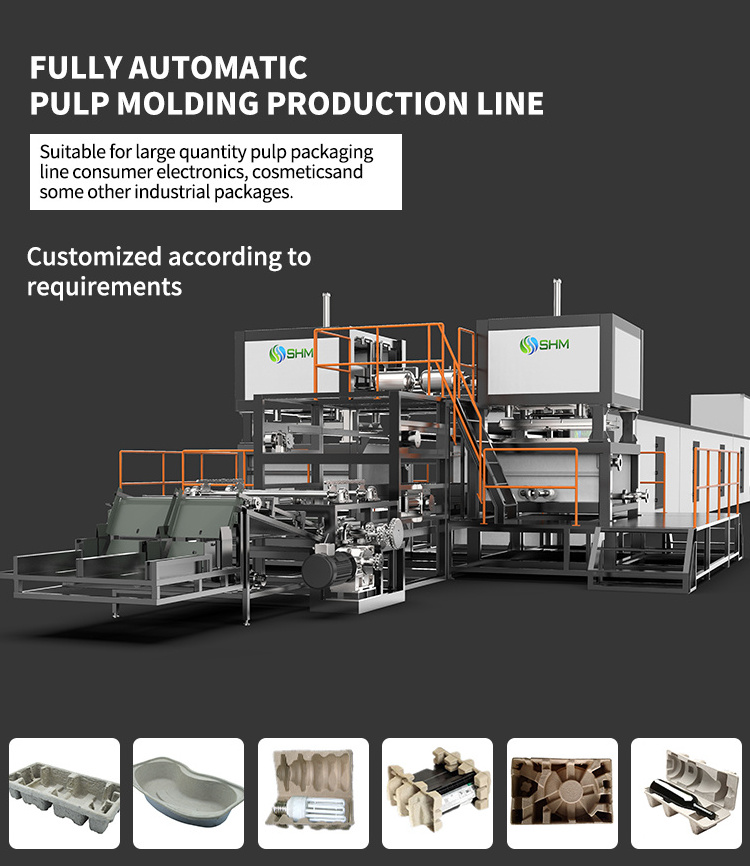

Disposable eco friendly paper plate making machine pulp fruit tray molding machine

Disposable eco friendly paper plate making machine pulp fruit tray molding machine

Fruit Tray Making Machine

| Model No.: | SHW-6000 |

| Voltage: | 380V |

| Template Size: | 800*600mm (It can customize.) |

| Operating Speed: | 1-6 times /Minute |

| Production: | related to tray size |

| Total power: | 70KW |

| Trademark: | SHM |

|

Transport Package: |

Export Standard Package |

| Transportation size: | 1 of 20'GP |

| Labour needed: | 3 people/shift to operate the whole system. |

Machine Main Features

1. High precision,high stability;

2. Forming and hot-pressing two-in-one design;

3. Two hot pressing platen with one forming platen design, improve efficiency;

4. Off-line auto trimming, more stable;

5. Position, pressure and temperature can be adjusted accurately

CNC Mold Process Center

Mold raw material: Aluminum.

Cast aluminum are highly recommended for both forming and transfer mould. Compared with other material, cast aluminum mould character:

1. With higher corrosion resistance, proper strength, hardness and heat endurance

2. Have better durability;

3. Featured with better machine, which will shorten tooling cycle;

4. Widely used in molded pulp industry;

5. Surface is polished and proceed machining with CNC’s ensure precision.

Ability to make mould design and manufacture good quality mould for customers:

Mold raw material: Aluminum.

Cast aluminum are highly recommended for both forming and transfer mould. Compared with other material, cast aluminum mould character :

with higher corrosion resistance, proper strength, hardness and heat endurance have better durability;

featured with better machine, which will shorten tooling cycle;

widely used in molded pulp industry;

s urface is polished and proceed machining with CNC’s ensure precision.

We have also developed different molding dies, SHM devoted to the design and manufacture of pulp moulding dies, pulp moulding machines, hot pressing equipment and hot press diess. We accept customized pulp molding shape and molded pulp tray, such as fruits packing tray machine, vacuum forming making machine, paper fruit tray making machine, apple tray making machinery. etc.

Looking for a custom product, we offer prototype tooling in our work shop. With our sample machine we can produce in-house samples for product trials. This will ensure the product your customer needs is what they get.

Paper fruit tray making machine for sale, Stability of Control System

All systems involved in the paper pulp production process are closely linked with each other. The systems work automatically as per the operational settings. Therefore, a steady and durable control system is needed to make sure that each process is performed accurately and simultaneously.

Qualification Rate

Qualification rates directly reflect the productivity of the machine and also the working state of the molding machine. To manufacture efficient and up to the mark products, the mold should be clean, perfect in size and shape, and should be robust and sturdy. So you can get good quality degradable molded paper tableware.

Safety, Maintainability

Safety is an essential thing in the molding process. There are special training given to the workers working on the molding machines. Paper molding machines need to be cleaned on a regular basis to maintain their operational efficiency.

Find a qualified pulp moldin achine manufacturer.

You can find many pulp apple tray making machine suppliers and compare the price. But do not rely on the price only, quality and service are more important for a big project. Especially when you buy a customized pulp moulding machine, you need to find an experienced manufacturer.

How much money will you spend on this business?

Please know that the pulp moulding machine cost is not only the pulp molding machine price , y ou also need to take the construction cost, space cost, maintenance cost, labor force cost into consideration.automatic fruit box making forming machine

Please feel free to send us an inquiry if you want to consult this kind of automatic fruit box making forming machine We will make suggestions according to your requirement.

Why choose SHM?

SH Machinery ha s engaged in pulping molding filed since 1986.

Advantages includes:

1. 30 years technology accumulation for EU,USA PRODUCT manufacturers

2. Approvals from Top 10 USA packaging compan y

3. CE and ISO9001 certificate

4. OEM and ODM both accepted.

5. Own designing team for new products development

6. Quick delivery time for decent orders

7. 24 hours online sales/after sales services

Service ability:

1. Engineering services for existing molded fiber producers as well as tailored production equipment for expanding or start-up enterprises.

2. Full p roduction s ystems, s ingle p roduction l ine s ystems and m ultiple p roduction l ine s ystems

3. Project Schedule

4. Preparation of documents and drawings

5. Training of maintenance and operation personnel

6. Guide Assembly line installation

7. Electrical and mechanical design

8. System integration

Let's aim for a plastic free world with recyclable and compostable paper based packaging solutions!