- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Beijing, China

-

Color:

-

Transparent

-

Operating Temperature:

-

1250℃

-

SoftenTemperature:

-

1730℃

-

Size:

-

Customers' Requests

-

Sample:

-

available

-

High transmission:

-

above 85%

-

Specification:

-

OEM

-

Usage:

-

Semiconductor/heating

-

Shipping:

-

1-30days

-

Material:

-

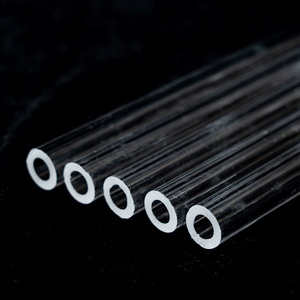

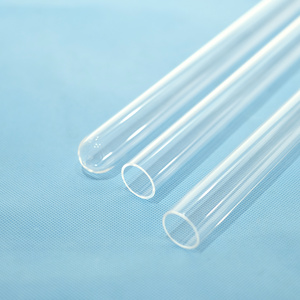

HIgh Purity Quartz Glass Tube

-

MOQ:

-

10

Quick Details

-

Type:

-

Clear Quartz Pipe

-

Application:

-

Semiconductor/heating

-

Outside Diameter:

-

0.5-400mm

-

Place of Origin:

-

Beijing, China

-

Color:

-

Transparent

-

Operating Temperature:

-

1250℃

-

SoftenTemperature:

-

1730℃

-

Size:

-

Customers' Requests

-

Sample:

-

available

-

High transmission:

-

above 85%

-

Specification:

-

OEM

-

Usage:

-

Semiconductor/heating

-

Shipping:

-

1-30days

-

Material:

-

HIgh Purity Quartz Glass Tube

-

MOQ:

-

10

1. high temperature resistant, High pressure cut quartz tube for tube furnace can work under 1200 °C continuously,and in short time can even work under 1450 °C ,

i ts softening temperature is 1650 °C ,and the melting temperature is 1750-1800°C.

2. Corrosion resistant, Except hydrofluoric acid, quartz tube do not react with any

acid and base except hydrofluoric acid .the stability is 30 tims of the ceramic ,and 150 times

of stainless steel .

3. Excellent thermal shock stability

4. High transmission to 85%

5. Electric insulation ,it is 10000 times of usual glass.

We can also produce opaque (Milky white) quartz tubes, ceramic heaters, quartz heaters, quartz

crucibles, etc.

Silicon Dioxide >99.95%, Excellent visual and chemical performance, high thermo-stability,

anticorrosive, Transmittance of visible light >90%. Deh-rodyolization available

upon customer request, deshydroxy content less than 20ppm, 15ppm, 10ppm,5ppm, or 2ppm.

Our products are used in areas of semiconductor, lighting and electric heating industries.

Please check following physical properties of our quartz tube.

| Density 20°C kg.m3(*1000) | 2.2 |

| Coefficient of expansion | 0.56 |

| Softening Point (°C) | 1670 |

| Annealing Point (°C) | 1210 |

| Strain Point (°C) | 1110 |

| Youngs Modulus (Pa) | 7.3*100000 |

1, Consistent quality control

2, Quick delivery time

3, Excellent customer support

4, Made-to-order service available

5, Assured interchangeability