Raytools laser cutting head has Z-axis servo function. Accufiber series of highly follower sensing cutting head using the principle of the capacitive sensor monitoring. It provides a stable and fast cutting height automatically adjusting function.Variety of nozzle supporting design almost can apply to any focal length lens. Its confocal features make sure the fixed-length body processing cutting head can install different focal lengths optical lenses. The focal length and nozzle height can be flexibly adjusted, including the XY direction the lens and coaxial nozzle adjustment.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500mm

-

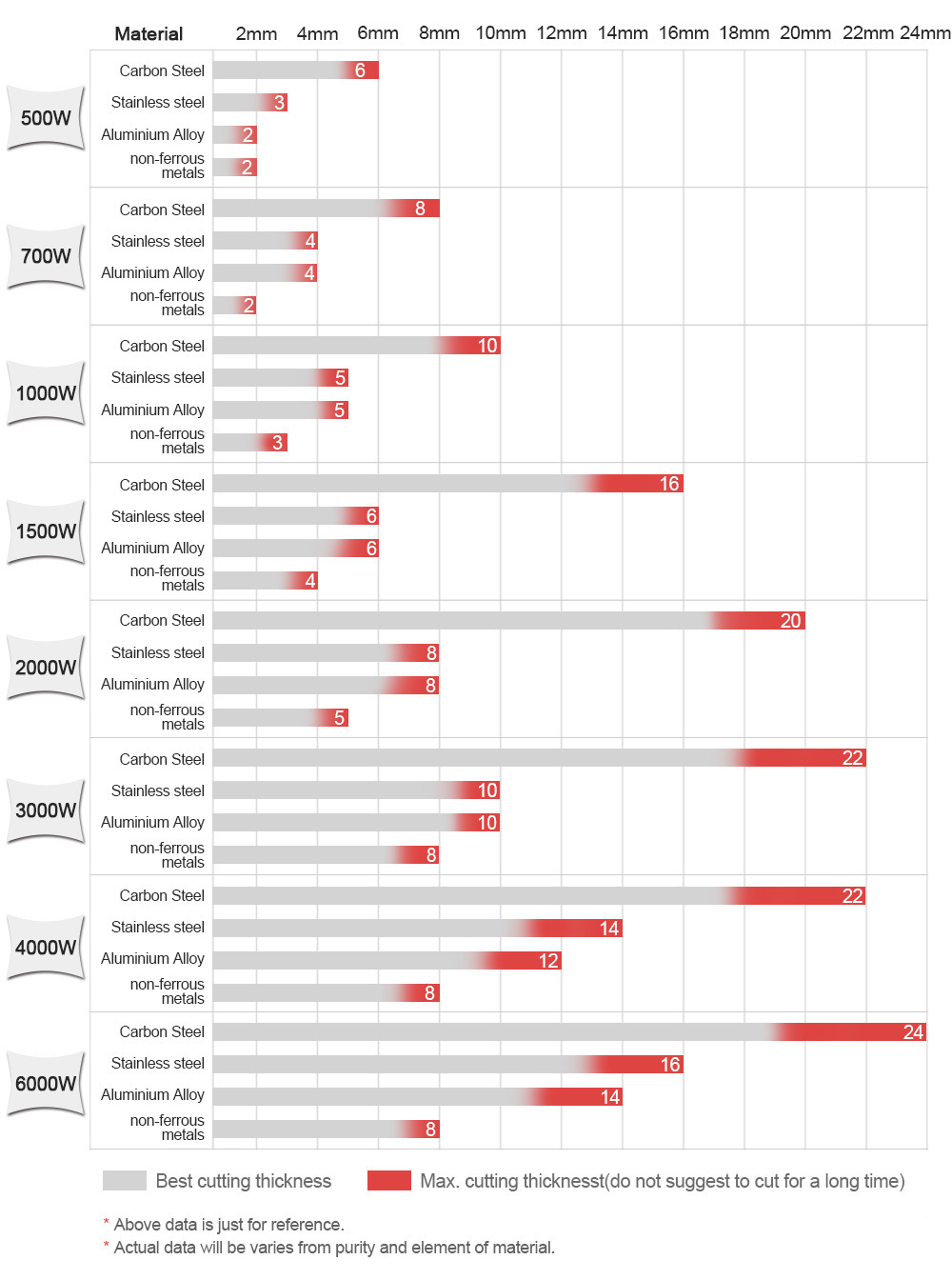

Cutting Thickness:

-

24 mm (carbon steel)

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Perfect Laser

-

Weight (KG):

-

2000 KG

-

Product name:

-

laser metal cutting machine

-

Dimension(L*W*H):

-

4.62*2.8*2.2m

-

laser power:

-

1000W/1500W,2KW,3.3KW, 4KW

-

Transmission Method:

-

Ball Screw/Gear Rack Transmission

-

location precision:

-

±0.05 mm

-

Control Method:

-

Offline Movement Control

-

Focus Method:

-

Following and Automatic Adjust Focus

-

Laser Technology:

-

Germany Technology

-

Transmission way:

-

Imported ball screw

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

5-30m / Minute

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

24 mm (carbon steel)

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Perfect Laser

-

Weight (KG):

-

2000 KG

-

Product name:

-

laser metal cutting machine

-

Dimension(L*W*H):

-

4.62*2.8*2.2m

-

laser power:

-

1000W/1500W,2KW,3.3KW, 4KW

-

Transmission Method:

-

Ball Screw/Gear Rack Transmission

-

location precision:

-

±0.05 mm

-

Control Method:

-

Offline Movement Control

-

Focus Method:

-

Following and Automatic Adjust Focus

-

Laser Technology:

-

Germany Technology

-

Transmission way:

-

Imported ball screw

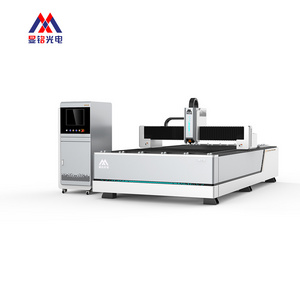

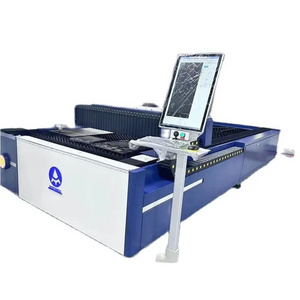

1000W 1500W 2000W 3000W 4000W Max Raycus IPG CNC Metal SS Aluminum Copper Sheet Tube Pipe Fiber Laser Cutters Cutting Machines

(Model:PE-F3015)

Contact:Emma whatsapp/wechat:+86

13886034275

Skype: perfectlaser020

Email:

sales020@perfectlaser.net

Product Description

Product Introduction

Product Application

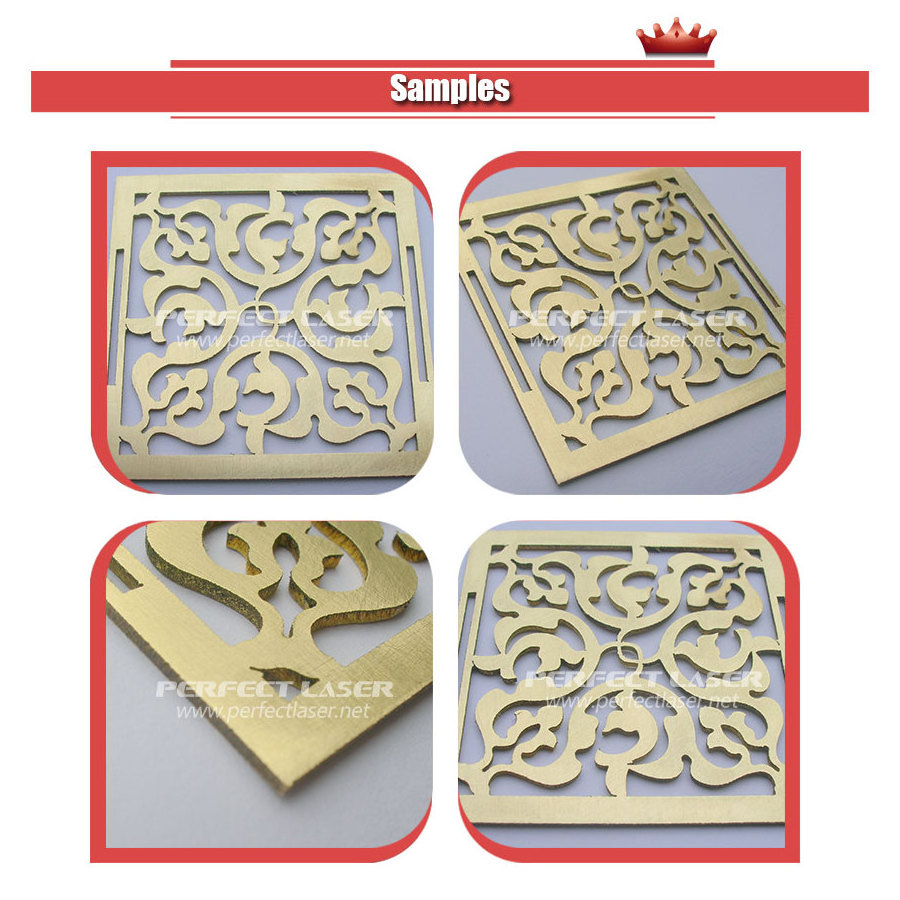

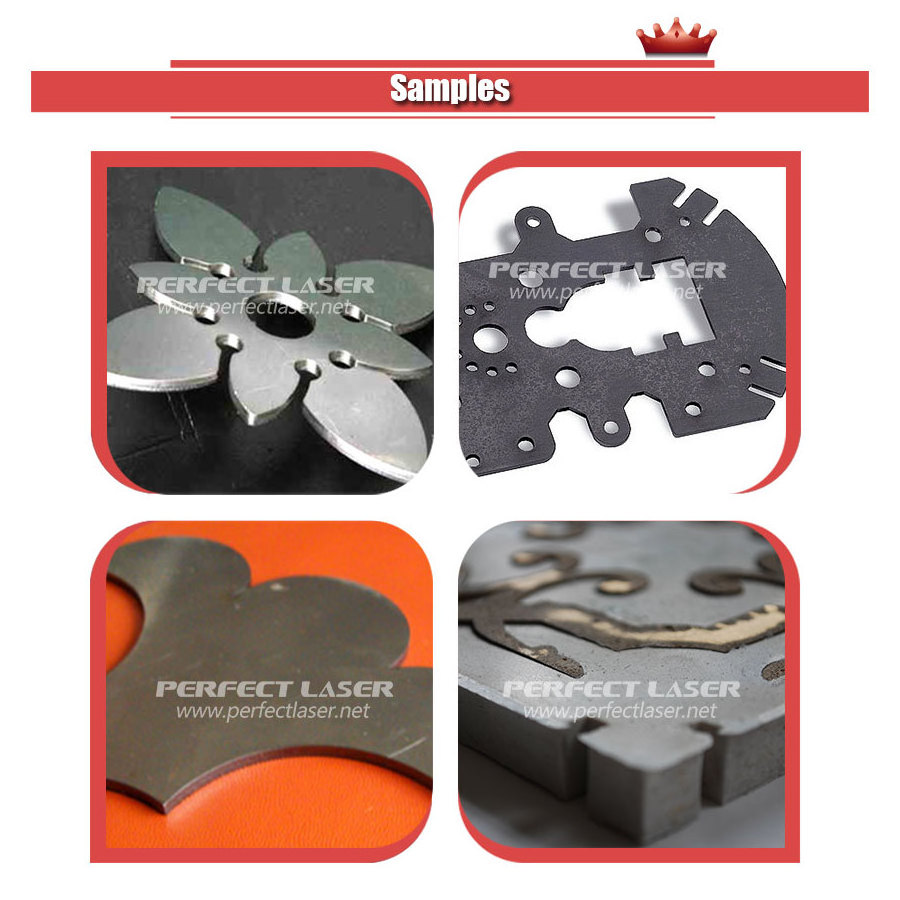

»Applied materials

The fiber laser marking machine is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

The fiber laser marking machine is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

»Applied Industries

The fiber laser cutting machine is applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

The fiber laser cutting machine is applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Machine Details

Advantages

*

Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

* High cutting speed: Cutting speed is more than 20m/min

* Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

* High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine has three times photoelectric conversion efficiency

* Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. Fiber line transmission no need reflect lens, save maintenance cost;

* Easy operations: fiber line transmission, no adjustment of optical path;

* Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.

* High cutting speed: Cutting speed is more than 20m/min

* Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

* High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine has three times photoelectric conversion efficiency

* Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. Fiber line transmission no need reflect lens, save maintenance cost;

* Easy operations: fiber line transmission, no adjustment of optical path;

* Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.

1. Advanced Laser Optical System

Ensure Excellent Laser Beam Quality Double-Xenon-lamp technology,can strongly improve the laser power and laser beam quality.

2. Heavy Machine Body

Adopt 100mm*100mm*6mm thick, square metal tube Stable, Heavy Loading,won’t distortion after long-time using. Worktable Max. Load can reach 500 kgs. Adopt a funnel-type machine bed design, Work with conveyor belt, Easy for user to get the cutting pieces from the machine front.

3. Auto transfer system

Can automatically transfer the cutted work-pieces into the front of machine, Improve working efficiency,Save labor energy, No need user to take it by hand. Make the work-pieces neat and beautiful.

4. Auto-feeding Design

Adopt feeding wheel design, Make the material feeding easier, Labor energy saving.

5. Laser Source

Adopt USA imported Laser Xenon lamp, Double lamp Technology .Strongly improve the power and laser beam quality.

6.Saw-tooth Type Working Table

Stable, Heavy Holding.

7. DSP Control Panel

East to operate, Enable remote control.

8.Professional Laser Cutting Software

Adopt CNC 2012 latest version, with powerful editing function,friendly interface, Easy to Use. Supports DXF, PLT, G-Code and many graphs.

Ensure Excellent Laser Beam Quality Double-Xenon-lamp technology,can strongly improve the laser power and laser beam quality.

2. Heavy Machine Body

Adopt 100mm*100mm*6mm thick, square metal tube Stable, Heavy Loading,won’t distortion after long-time using. Worktable Max. Load can reach 500 kgs. Adopt a funnel-type machine bed design, Work with conveyor belt, Easy for user to get the cutting pieces from the machine front.

3. Auto transfer system

Can automatically transfer the cutted work-pieces into the front of machine, Improve working efficiency,Save labor energy, No need user to take it by hand. Make the work-pieces neat and beautiful.

4. Auto-feeding Design

Adopt feeding wheel design, Make the material feeding easier, Labor energy saving.

5. Laser Source

Adopt USA imported Laser Xenon lamp, Double lamp Technology .Strongly improve the power and laser beam quality.

6.Saw-tooth Type Working Table

Stable, Heavy Holding.

7. DSP Control Panel

East to operate, Enable remote control.

8.Professional Laser Cutting Software

Adopt CNC 2012 latest version, with powerful editing function,friendly interface, Easy to Use. Supports DXF, PLT, G-Code and many graphs.

Product Paramenters

|

Model

|

PE-F3015

|

|

Laser Technology

|

Germany Technology

|

|

Laser Source

|

Germany Import Laser Fiber Laser Source IPG/Raycus/Max

|

|

Max. Cutting Speed

|

5-20 Meters / Min (Up to Materials)

|

|

Max. Location Speed

|

90m/min

|

|

Laser Wavelength

|

1080nm

|

|

Minimum Line Width

|

≤0.1mm

|

|

Location Precision

|

≤±0.01mm

|

|

Re-Location Precision

|

±0.01mm

|

|

Max. Moving Speed

|

100m/min

|

|

Supporting Format

|

PLT, DXF, BMP, AI

|

|

Power Demand

|

380V/50HZ, 3phases or 220V,50HZ 1 phase/3 phases

|

|

Cooling Way

|

Water Cooling

|

|

Worktable Max. Load

|

1000kgs

|

|

Transmission Method

|

Ball Screw Transmission

|

|

Table-driven system

|

Japanese Imported Servo Motor & Driving System

|

|

Focus Method

|

Following and Automatic Adjust Focus

|

|

Control Method

|

Offline Movement Control DSP

|

|

Control software

|

Professional Laser Cutting Software Cypcut or Weihong

|

Related Products

We have several main products as following :

1.Fiber Laser Cutting Machine

2. Fiber Laser Marking Machine

3. Dot Peen Marking Machine

4. Co2 Laser Engraver and Cutter

5.3D Crystal Laser Engraver

1.Fiber Laser Cutting Machine

2. Fiber Laser Marking Machine

3. Dot Peen Marking Machine

4. Co2 Laser Engraver and Cutter

5.3D Crystal Laser Engraver

Marketing Compaign

Service:

The guarantee period of quality shall be 12 months counting from the date on which the commodity arrives at the port of destination. Except the damage artificially and laser crystal rod and laser lamp, we are responsible for offering the fittings free of charge during the guarantee period, while it is preferred you send the damaged fittings to us by courier with your charge for our testing, after confirming damage, we will send back the alternative fittings to you. After the guarantee of quality period, the parts required repairing or change, if any, shall be paid.

When you meet some complicated problem and online-support can not solve it, we can offer Door-Visiting Service. If our engineer to assemble or/and maintain or/and adjust the machine is/are required, we shall assist to deal with the visa formality and prepaid traveling expenses and accommodation to us during the business trip and the service period before their dispatch. And you can arrange for the translating person for the service engineer during their service period. Or you can send your engineer to China. We will offer long-term technical training to him for free.

Hot Searches