- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

soap making machine

-

Product name:

-

Bar Soap Making Machine Mini Toilet soap Making Machine

-

Application:

-

soap making machine

-

Capacity:

-

CUSTOMIZED

-

Certificate::

-

CE

-

Usage:

-

bar soap making machine

-

VOLTAGE:

-

Custom-tailor

-

Function:

-

soap making machine price

-

Advantage:

-

High efficiency

-

PACKING:

-

wooden case

-

Keywords:

-

Easy operation

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZZHL

-

Weight (KG):

-

5000

-

Machine Type:

-

soap making machine

-

Product name:

-

Bar Soap Making Machine Mini Toilet soap Making Machine

-

Application:

-

soap making machine

-

Capacity:

-

CUSTOMIZED

-

Certificate::

-

CE

-

Usage:

-

bar soap making machine

-

VOLTAGE:

-

Custom-tailor

-

Function:

-

soap making machine price

-

Advantage:

-

High efficiency

-

PACKING:

-

wooden case

-

Keywords:

-

Easy operation

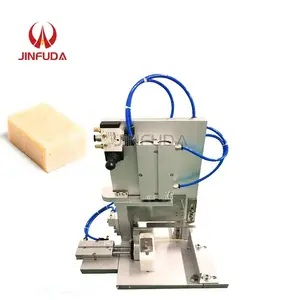

High Quality Small Liquid Bar Soap Making Machine Mini Toilet soap Making Machine Production line

Product Description

Features:

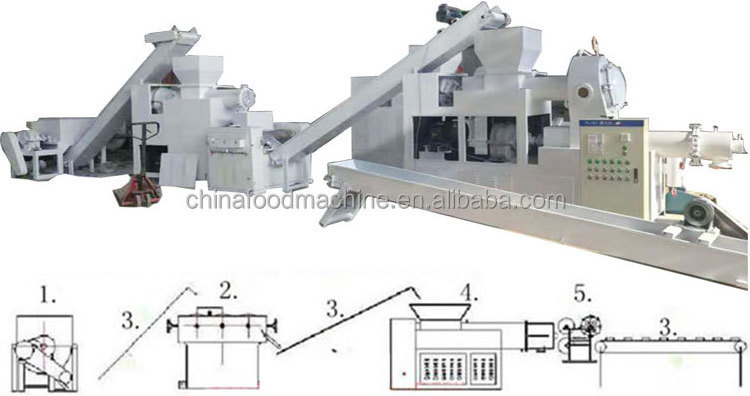

a. This system can continuously produce laundry soap, compound soap, industrial soap and others;

b. The production line is mainly consisting of oil refining, saponification, vacuum drying and extrusion;

c. Only when the crystal form of soap is tiny, the soap become fine and smooth. The vacuum drying system can make the soap to form tiny and compact crystal texture which is mainly in the shape of β base;

d. When you produce fatty acid products( laundry soap, compound soap and industrial soap), the fatty acid content is usually 49%, the vacuum degree of the system is about of 740 mmHg, the temperature of soap base is 85 0C, vacuum dewatering is about 4%, you

can take 53% fatty acid.

Production process of Mini Soap Making Machine Price:

Mix and melt oil --> Saponification --> Vacuum drying --> Soap noodle --> Grinding --> Vacuum Plodder (extruding) --> Cutting.

Available complete set of Mini Soap Making Machine Price

1)capacity: 100—500KG/Hour

2)capacity: 600—1000KG/Hour

3)capacity: 1200—1500KG/Hour

4)capacity: 1500—2000KG/Hour

b. The production line is mainly consisting of oil refining, saponification, vacuum drying and extrusion;

c. Only when the crystal form of soap is tiny, the soap become fine and smooth. The vacuum drying system can make the soap to form tiny and compact crystal texture which is mainly in the shape of β base;

d. When you produce fatty acid products( laundry soap, compound soap and industrial soap), the fatty acid content is usually 49%, the vacuum degree of the system is about of 740 mmHg, the temperature of soap base is 85 0C, vacuum dewatering is about 4%, you

can take 53% fatty acid.

Production process of Mini Soap Making Machine Price:

Mix and melt oil --> Saponification --> Vacuum drying --> Soap noodle --> Grinding --> Vacuum Plodder (extruding) --> Cutting.

Available complete set of Mini Soap Making Machine Price

1)capacity: 100—500KG/Hour

2)capacity: 600—1000KG/Hour

3)capacity: 1200—1500KG/Hour

4)capacity: 1500—2000KG/Hour

Material needed

There are two sources of raw materials:

1.

soap particles (

above

picture

)

2.Oil or fat of plant or animal (palm oil, coconut oil, tallow oil, etc.), caustic soda (NaOH), sodium-chloride (NaCl), sodium silicate, pigment, etc.

Processing Equipment

1. Raw materials

2. Production requirements

3. Finished product: shape, weight, size, etc.

According to the above information provided by customers, we can provide professional, timely and effective solutions

Finished product

Customer's finished product requirements.

Option I

This production line is a soap molding production line with

soap particles

as raw material an output of 500-1000 kg/h. After raw material mixing, grinding, vacuum stripping, electronic rolle printing and cutting/Auto Stamping machine.high-grade soap with a fatty acid content of 35-70 can be produced. The production line adopts a double-layer vacuum ejector, which can make th soap structure compact and difficult to crack.

Option II

This soap production line regard

soap noodles as raw materials or palm oil

.The production starts with mixing soap noodles or palm oil . Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made. The soap thin sheet then converted into desired long strip soap by the plodder machine.Then the long strip soap are cut into the soap bars required size by cutting machine(there are two kinds of cutting machine.One is mechanical.The other is automatic).Finally, the soap bars gets packed by packing machine if needed.

Machine composition

Soap mould

Vacuum pump

Low temperature chiller

Customers visit the factory

Related Products

*If you can not open the links above on Alibaba APP on mobile phone, please use IE browser to visit our website:

https://chinafoodmachine.en.alibaba.com

https://chinafoodmachine.en.alibaba.com

Packaging & Shipping

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Certifications

Customer Photos

Our Team

Contact us

Need more machine details or video ? Please contact us directly

Hot Searches