- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.03

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SPX

-

Dimension(L*W*H):

-

referring

-

Weight:

-

520 KG

-

Product name:

-

Liquid filling machine

-

Material:

-

304# stainless steel

-

Function:

-

Pen Tube Filling And Capping Machine

-

Keyword:

-

Semi-automatic Filling Machine

-

Usage:

-

filling machine

-

Component:

-

Motor,PLC,Pump,Bearing,Engine,Gearbox

-

Air pressure&Voltage:

-

0.6-0.8Mpa 220V/ 50HZ, 2 phase

-

Control style:

-

PLC system + English interface

-

Opening way:

-

Electric

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 100BPH, 200BPH

-

Packaging Material:

-

Wood, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

0.03

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SPX

-

Dimension(L*W*H):

-

referring

-

Weight:

-

520 KG

-

Product name:

-

Liquid filling machine

-

Material:

-

304# stainless steel

-

Function:

-

Pen Tube Filling And Capping Machine

-

Keyword:

-

Semi-automatic Filling Machine

-

Usage:

-

filling machine

-

Component:

-

Motor,PLC,Pump,Bearing,Engine,Gearbox

-

Air pressure&Voltage:

-

0.6-0.8Mpa 220V/ 50HZ, 2 phase

-

Control style:

-

PLC system + English interface

-

Opening way:

-

Electric

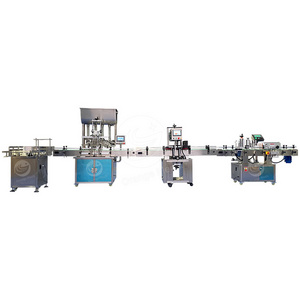

Product Information

Features:

○ It has a high degree of automation, high yield, wide adaptability, good stability and other characteristics.

○ Detection: the photoelectric sensor detects whether there is empty bottle on the working rotary chuck, and sends the detection signal to the control. In the computer, it is used to control the filling with bottle, no filling without bottle.

○ Filling: If a bottle is detected in the front, PLC controls the filling nozzle to go into the bottle for filling.

○ Gland: the upper and lower gland is controlled by the CAM to ensure that the lower limit of the cap is in place.

○ Bottle out: the final capped bottle out of the conveyor belt.

○ Reasonable design, compact models, easy to operate, pneumatic parts are used in Taiwan AIRTAC pneumatic components.

○ Material contact parts are made of SUS304 stainless steel material, corrosion resistance, in line with GMP requirements.

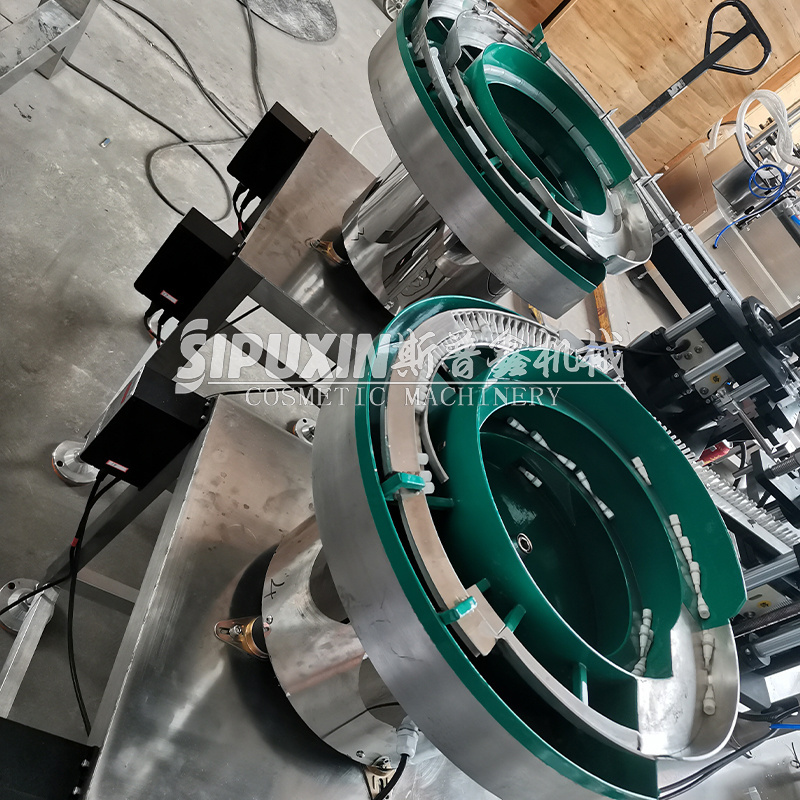

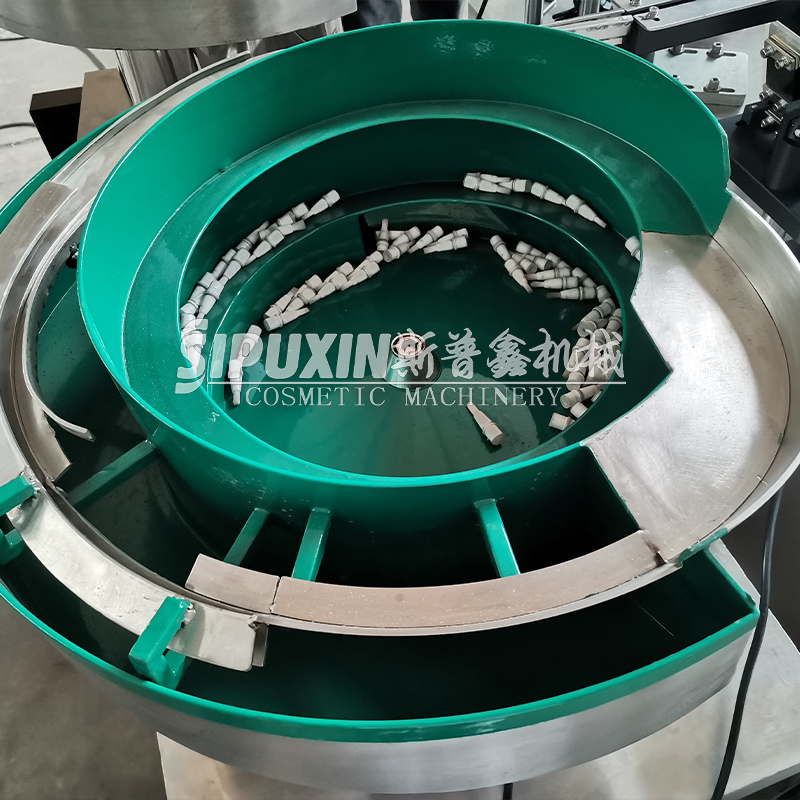

Inner dropper vibration plate & pressing device

The inner side of the vibrating plate is provided with a spiral channel, and the inner side of the vibrating plate is provided with a pressure cap. The movable frame drives the vibrating plate to vibrate, so that the material transfer effect is better and the degree of automation is stronger. Caps are conveyed to the conveyor belt.

Outer seal cap vibration plate i& screw capping device

The vibrating disc drives the cap vibrating disc to vibrate, so that the cap is transferred to the bottle, the degree of automation is stronger, the structure is simple, the work intensity of the staff is reduced, and the cap is conveyed to the conveyor belt

PLC control panel

The touch-screen control panel uses Siemens world-renowned brands,wt garant uty ntfor the operator to operate various funetions, adjustabl trequency, quick st n o very sensitive. Different languages can be selected.

Bottle transfer conveyor

The belt-type automatic conveyor belt saves time and labor costs, is safe to operate, easy to use, easy to maintain, automatic transmission, high efficiency, and reduces engineering costs. The traction chain has high strength. Frequency conversion speed regulation, stable and reliable operation.

Filling Head

Automatic filling beight and position cn be aduated arbitrarily, and the ed falls in sraight line wih the liquid level in the bottle to avoid liquid splashing and contaminating the bottle and conveyor belt.

Machine Air Supply Connection

It is used to filter the water carried in the compressed gas, isolate the water vapor from the air by filtering the oil and then store the water vapor in the.water storage reservoir. Therefore, it is necessary to release the accumulated water every day when using it. It has its own pressure display and air pressure adjustment.

Blower

Through the air blowing device to blow dry the water in the bottle, keep the bottle dry, prevent contamination to the product, maintain the purity of the product.

Push Cap

The precise positioning and clamping of the bottle cap and the bottle is realized, the pressing operation of the bottle cap is convenient, the complicated positioning process is omitted, and the labor force of the workers is greatly reduced. The capping device should hold the bottle tightly when capping to prevent the bottle from rotating when capping. Automatic induction capping and capping system, integrated optical fiber, does not work without bottle.

Related Product

Hot Searches