- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/400V/415V and other

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

5000 kg

-

Marketing Type:

-

New Product 2022

-

material:

-

stainless steel

-

Raw material:

-

fish meal, corn powder, wheat flour and other

-

Usage:

-

fish feed machine

-

Capacity:

-

100-2000kg/h

-

Motor:

-

ABB, Siemens, China Brand

-

fish feed size:

-

1mm-10mm

-

barrel:

-

45#steel

-

screw:

-

38CrMoAl

-

keyword:

-

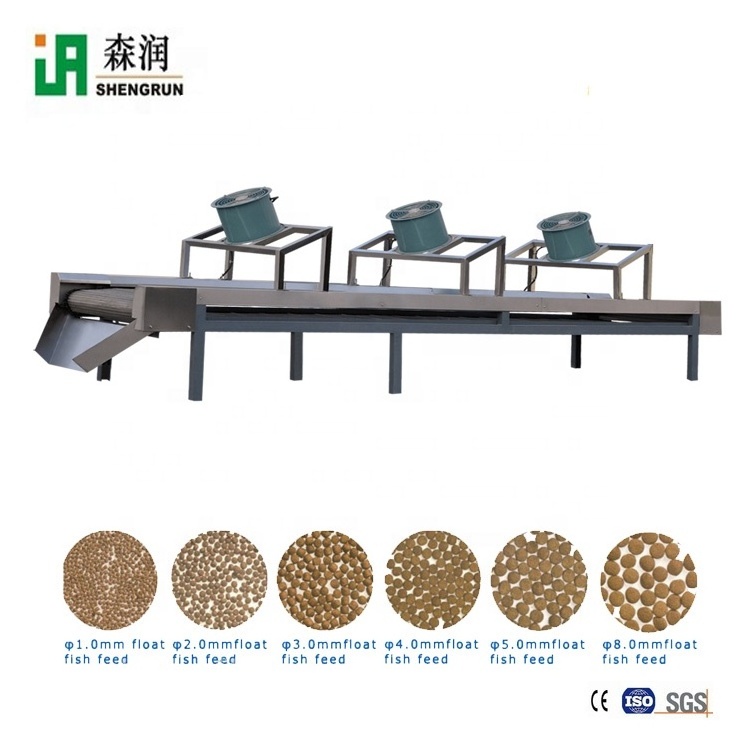

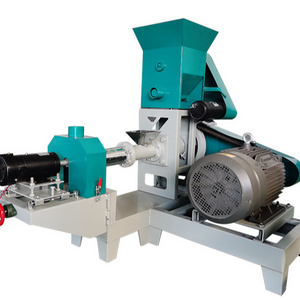

Fish Food Extruder / Floating Fish Feed Pellet Machine

-

Product name:

-

Floating feed pellet making fish food machine

Quick Details

-

Max. Capacity:

-

5 ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shengrun

-

Voltage:

-

380V/400V/415V and other

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

5000 kg

-

Marketing Type:

-

New Product 2022

-

material:

-

stainless steel

-

Raw material:

-

fish meal, corn powder, wheat flour and other

-

Usage:

-

fish feed machine

-

Capacity:

-

100-2000kg/h

-

Motor:

-

ABB, Siemens, China Brand

-

fish feed size:

-

1mm-10mm

-

barrel:

-

45#steel

-

screw:

-

38CrMoAl

-

keyword:

-

Fish Food Extruder / Floating Fish Feed Pellet Machine

-

Product name:

-

Floating feed pellet making fish food machine

tropical fish food pellet extruder making pellet mill machinery floating fish feed production line

The fish feed-making machine is used to produce different kinds of pet food, floating fish feed, and sinking feed. It works with simple operation and accurate parameter control. The products can be finished at the stipulated temperature, pressure, humidity, and time. Owing to the reasonable design, special materials, the stability, repairs can be guaranteed and ensured. The various shape and tastes must meet the different requirements of pet food.

1.1 Voltage of floating fish pellet-making machine

Three phases: 380V/50Hz, Single phase: 220V/50Hz.

we can make it according to customers' Local voltage according to different countries.

1.2 Capacity of floating fish pellet-making machine

100kg/h - 150kg/h; 200-250kg/h; 300-500kg/h; 500-800kg/h; 800-1000kg/h; 1-2ton/h etc

1.3 The parameter of the floating fish pellet making machine

| MODEL | INSTALLED POWER | REAL POWER | OUTPUT(KG/H) | DIMENSION(MM) |

| DLG60 | 16.5KW | 15KW | 100-150 | 1200*600*1500 |

| DLG80 | 23.5KW | 22KW | 200-300 | 1200*600*1500 |

| DLG120 | 66KW | 55KW | 500-600 | 2600*900*1900 |

| TSE65 | 80KW | 50KW | 100-150 | 2600*900*1900 |

| TSE70 | 110KW | 80KW | 200-250 | 2600*1200*1900 |

| TSE85 | 150KW | 100KW | 350-500 | 3900*1500*1900 |

| TSE90 | 170KW | 120KW | 600-900 | 4200*1800*2500 |

| TSE95 | 190KW | 150KW | 800-1500 | 4200*2200*2800 |

| TSE120 | 230KW | 200KW | 2000-3000 | 5200*2500*3800 |

| TSE140 | 290KW | 240KW | 3000-5000 | 6800*2800*4200 |

1.4 Samples of floating fish pellet/ animal feed/ pet food etc

2.1 Twin-screw extruder

1.The main extruder adopts frequency speed controlling with high automation.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system ,which can guarantee the equipment transmission life longer.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

5.It has the widest range of applications and can produce different products with different equipment and models.

2.2 Multi-layer dryer

1. We have four types of dryers, which includes fuel ovens, gas ovens, electric ovens, and high-temperature inflated ovens (used to produce cornflakes).

2. Dryer is compact and has a small dry area and a large superficial area. It also features a small scale of heat elimination and high thermal efficiency.

3. Mesh belt conveyors and thermal insulation boards all use stainless steel material, making the equipment clean and sanitary.

4.Mesh belt conveyors and thermal insulation boards all use stainless steel material, making the equipment clean and sanitary.

5. The speed of mesh belt conveyor is adjustable, the drying period for food in the oven can be adjusted.

6. The automatic temperature control system makes it possible to set the temperature according to your needs.

2.3 Flavoring line

1. Spray the oil in the roller.

2. The inside turning container is very sanitary because of adopting the stainless steel material.

3. Material touching food is stainless steel.

4. The inside of the roller is also uneven, the main purpose is to more evenly season.

In order to ensure the quality of the machine, the accessories used by the company are mostly domestic or international well-known brands.

Now there are 100 countries people using our equipment including our agents' clients. Not only can our after-sales engineers provide on-site service, but our agents in India, Nigeria, and Peru can also help our customers quickly solve their problems. You can receive professional service.

-- Before sale service

1. Provide free consultation on the equipment.

2. Provide the standard device and the flow chart.

3. According to the client's special requirements, offering a reasonable plan and free design helps to select the equipment.

--Services during the sales:

1. Help the client design the factory and offer professional advice, and free engineering drawing for the factory layout

2. Welcome to visit our factory or the domestic clients’ factory.

3. Inspect the machine before leaving the factory.

--After-sale services:

1. Overseas installation and debugging of the equipment.

2. Train the first-line operator.

3. Provide the basic formula.

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. 1-2 engineers will be arranged for the customer

1. Testing Machine before package.

2. Packaging: inside is covered in plastic film, outside is a wooden case.

3. Shipping: 15-35 working days after receiving the deposit.

1. What's the pre-sale service of your company?

Related machines’ technical parameters will be supplied to the customer.

1. According to the customer’s factory size, the factory layout can be provided in

advance.

2. According to the customer’s material cost, general formulation can be

prepared well.

3. Special machines can be supplied at the customer’s request.

4. Professional Advice about Markets, machines, processing, materials,

and packing can be supplied.

5. Suggesting professional shipping agent or helping book ship as customer

request.

2. What's the after-sale service of your company?

1. Allocation chart as the buyer’s request will be supplied.

2. Operation manual will be supplied after shipment.

3. One-year warranty, lifetime maintenance with cost price.

4.

Free easy broken spare parts will be sent with a container.

5. The first installation can be done by an engineer.

6. Training workers in customer factories.

3. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer videos.

4. What are the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.