- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

Depend on capacity

-

Item:

-

solid fuel wood pellet boiler with stoker

-

Design fuel:

-

coal, wood, chips, pellet, husk, etc

-

Thermal efficiency:

-

85%

-

Rated steam capacity:

-

1-10 ton/h

-

Rated working pressure:

-

0.7/1.0/1.25/1.6/2.5Mpa

-

Rated steam temperature:

-

170/184/194/204/225C

-

Feed Water Temperature:

-

20C

-

Application:

-

rice mill, sugar mill, food and beverage, textile and Printing etc

-

Color:

-

Customer's Requirement

-

Fuel consumption:

-

151-1160 kg/h

Quick Details

-

Steam Production:

-

Max. 10t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XinLi

-

Dimension(L*W*H):

-

Depend on capacity

-

Weight:

-

Depend on capacity

-

Item:

-

solid fuel wood pellet boiler with stoker

-

Design fuel:

-

coal, wood, chips, pellet, husk, etc

-

Thermal efficiency:

-

85%

-

Rated steam capacity:

-

1-10 ton/h

-

Rated working pressure:

-

0.7/1.0/1.25/1.6/2.5Mpa

-

Rated steam temperature:

-

170/184/194/204/225C

-

Feed Water Temperature:

-

20C

-

Application:

-

rice mill, sugar mill, food and beverage, textile and Printing etc

-

Color:

-

Customer's Requirement

-

Fuel consumption:

-

151-1160 kg/h

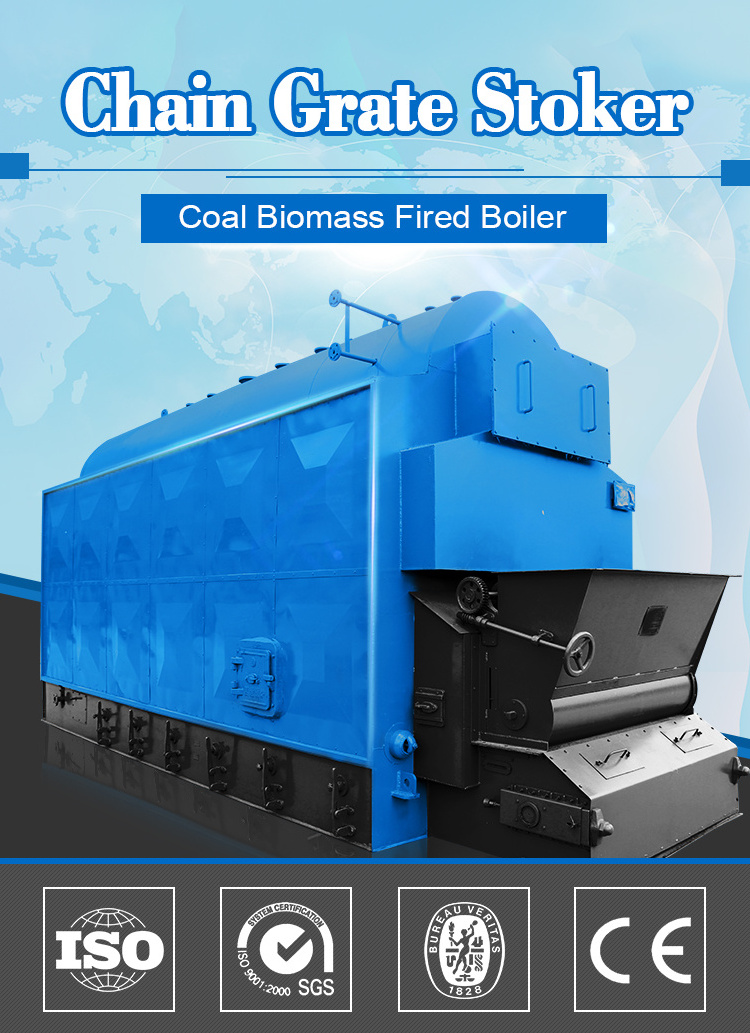

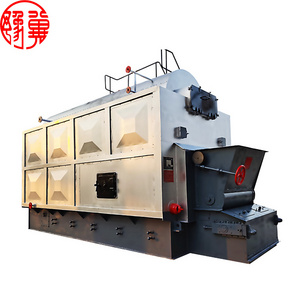

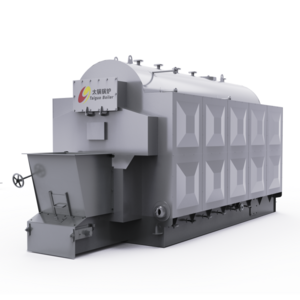

DZL series coal biomass fired boiler is single drum water tube and fire tube boiler, combustion equipment is chain grate. Water wall tubes at left and right sides of furnace are the radiated heating area. the two wings at furnace and screw fire tube in the drum are convection heating area. This boiler uses the upper drum, water wall tube and head are in symmetrical arrangement mode. This furnace structure in reasonable arrangement and high efficiency. This series boiler adopts several environmental protect measures (bag dust collector, double towers desulfurization, etc.) to meet the national emission requirement.

This boiler uses the new scientific achievement, such as arch tube plate and corrugated tube, to solve the problem of tube plate flaw and water wall tube explosion, improve the heat transfer efficiency and thermal efficiency, increase the output. The boiler is wide adoptability of different fuels, such as coal, biomass fuel, wood, straw, bagasse, rice husk, coconut shell, etc.

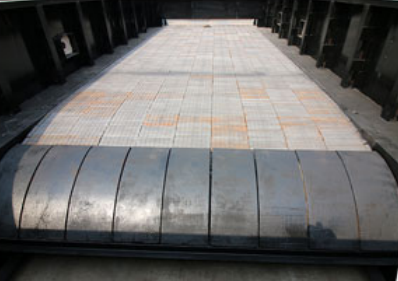

Chain Grate Stoker

Mechanization to reduce labor intensity

Layer burning + suspension combustion

Eight Character Wall

Low original dust concentration

Environgmental protection

Thread Smoke Tube

Enhance heat transfer

Flue gas disturbance, self - cleaning

Arched Tube Plate

BEFORE

(1) 24 hours customer service online, and offer professional technical support within 48 hours.

(2) Help design the specific boiler and efficient energy utilization plan individually.

(3) Offer factory inspection service, make arrangement including pick up, meal, accommodation, etc.

DURING

(1)Guarantee high product quality and punctual delivery deadline.

(2)Door-to-door installation service by the professional installation team with 50 senior engineers.

AFTER

(1) 24 months warranty period.

(2)The technical teams will visit customers for after sale service every quarter.

Q1: How to get the best price quickly?

1)Please offer the boiler capacity & pressure you need, and the fuel you plan to use, then we could offer the suitable boiler model.

2)Please provide your name, email address, WhatsApp/WeChat/Skype, and company name, then we will send the best price and boiler details immediately.

Q2: How to ensure the boiler quality?

(1)Strength calculation report for applied materials information;

(2)100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3)100% X-ray inspection(welding seam): ensure the quality of entire boiler;

(4)Hydrostatic test: ensure the standard working pressure and safety;

(5)Third-party inspection report: Henan Boiler Inspection Institute;

(6)Passed ISO:9001,CE, SGS and Intertek certificate.

Q3: What about the installation and Commissioning?

After you receive the boiler, we will guide you to make some preparation for installation, and our experts will offer overseas installation service if you need, and fly to the installation site within 72 hours.

Q4:What is the using life of your boiler?

Normally the boiler is designed for 15 years life span, but with correct operation and well maintenance, the boiler operation life will be longer.

Q5: After Sales Service

1)Guarantee Period:12 months from the date of trial run finish, but not to exceed 18 months from date on which the goods leave factory.

2)If any parts (excluding easily damaging parts) are found defective in quality in the first year, we will replace free-of-cost.