- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

4KW

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

1100

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Airflow Dryer Drying Machine

-

Product Type:

-

Air Flow Drying Machine

-

Function:

-

Sawdust Dryer

-

Advantage:

-

Fast Drying Speed

-

Application material:

-

Sawdust Biomass

-

Heating source:

-

Firewood

-

Usage:

-

Airflow Pipe Dryer

-

Keywords:

-

Wood Dryer Machine

-

Key words:

-

Sawdust Drying Machine

-

Key word:

-

Wood Sawdust Rotary Dryer

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SONGBAI

-

Voltage:

-

220V/380V

-

Power:

-

4KW

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

1100

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Airflow Dryer Drying Machine

-

Product Type:

-

Air Flow Drying Machine

-

Function:

-

Sawdust Dryer

-

Advantage:

-

Fast Drying Speed

-

Application material:

-

Sawdust Biomass

-

Heating source:

-

Firewood

-

Usage:

-

Airflow Pipe Dryer

-

Keywords:

-

Wood Dryer Machine

-

Key words:

-

Sawdust Drying Machine

-

Key word:

-

Wood Sawdust Rotary Dryer

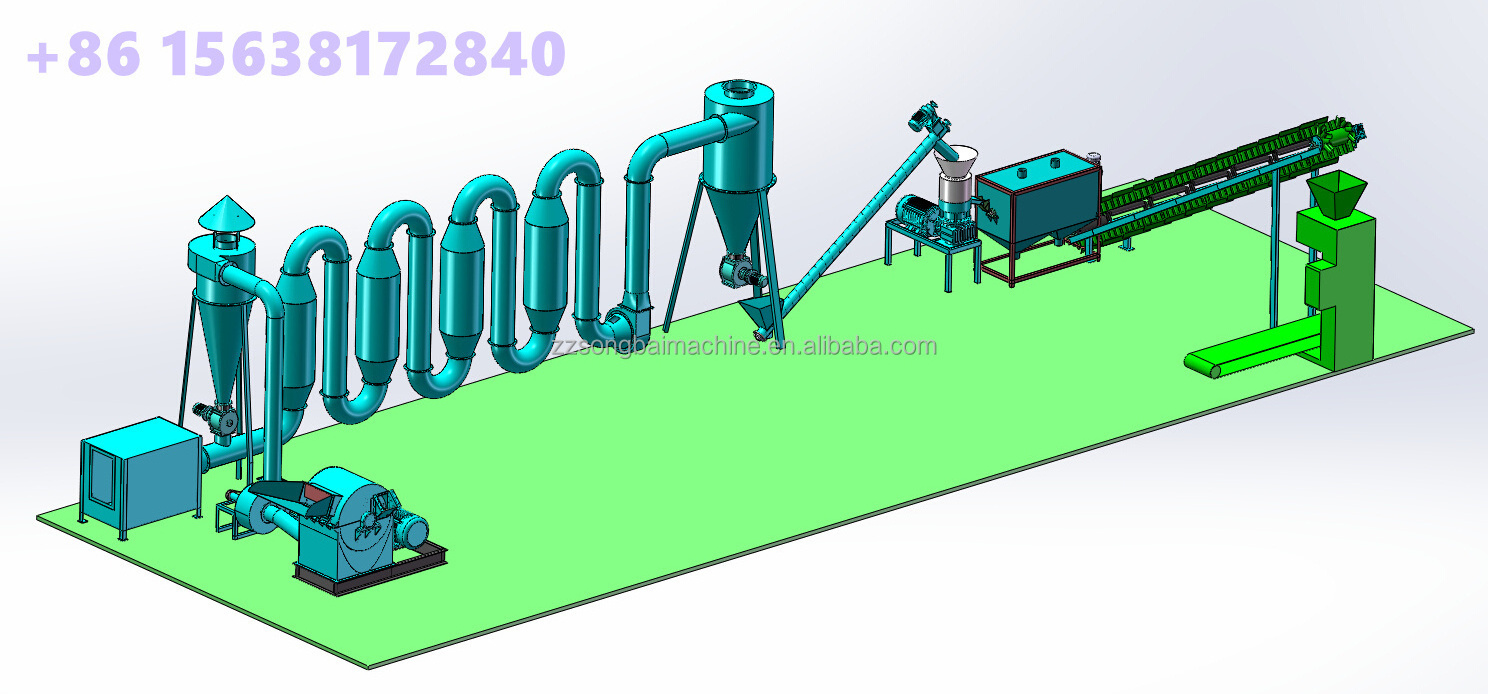

High Efficiency Wood Sawdust Dryer Airflow Type Wood Chipper Dryer Rice Husk Biomass Powder Airflow Dryer

Product Description

|

Introduce of Wood Sawdust Airflow Dryer Rice Husk Wood Chips Flash Dryer Hot Air Pipe Dryer

|

|

1. The Work Principle of hot air dryer machine engine air powder dryer machine

Hot airflow dryer using high speed flow steam to make wet materials suspend in it, in the process of the air flow (the time is instant, nearly 10~15s), the wet materials will be dried. Then the dried material will be outputted from the cyclone, used hot airflow and steam will be exhausted from the top of cyclone.

|

|

2. High heat transfer coefficient

Due to the high speed of hot airflow, the materials dispersing fully in the chambers, so nearly all of the materials surface can be dried. It means the larger heat transfer surface.

Instant drying time airflow speed is very fast, drive the materials to output in an instant, only 10~15 seconds. So it won’t influence the quality of thermosensitive materials or low-melting-point materials.

|

|

3. Easy operation of instruction, Less area occupied, Low investment and maintenance cost.

|

|

Airflow dryer can be used for wood pellet production line and carbon production line

|

|

Crushing -- Drying -- Pelleting -- Cooling -- Packing

|

Specification

Different Capacity Industrial Wood Sawdust Dryer Air Flow Pipe Dryer

According the the different drying capacity , we have many models for the wood sawdust dryer, you can check the below specification to check which model you prefer to , if you have any interest, you can contact us freely, we glad to provide more professional recommend to you.

|

Model

|

Capacity

(kg/h)

|

Power

(kw)

|

Packing Size

(mm)

|

Weight

(kg)

|

|

ZS-QH-220

|

300-500

|

4

|

Pipe: 2440*1230*1900

Stove: 1450*1420*1410

|

1100

|

|

ZS-QH-325

|

500-800

|

7.5

|

Pipe: 2450*1720*1910

Stove: 1450*1420*1410

|

1600

|

|

ZS-QH-400

|

800-1000

|

11

|

Pipe: 2450*1720*1910

Stove: 1450*1420*1410 |

1800

|

Product Show

Packing & Delivery

Automatic Wood Sawdust Airflow Dryer Packing and Shipping

Packed in standard wooden case

Shipping by sea

Hot Searches